Variable axial plunger pump

A technology for axial piston pumps and plunger pumps, which is applied in the direction of pumps, multi-cylinder pumps, liquid displacement machines, etc., and can solve the problems of expensive axial piston pump accessories, single variable control form, and difficult variable control. , to achieve the effect of compact structure, small volume and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

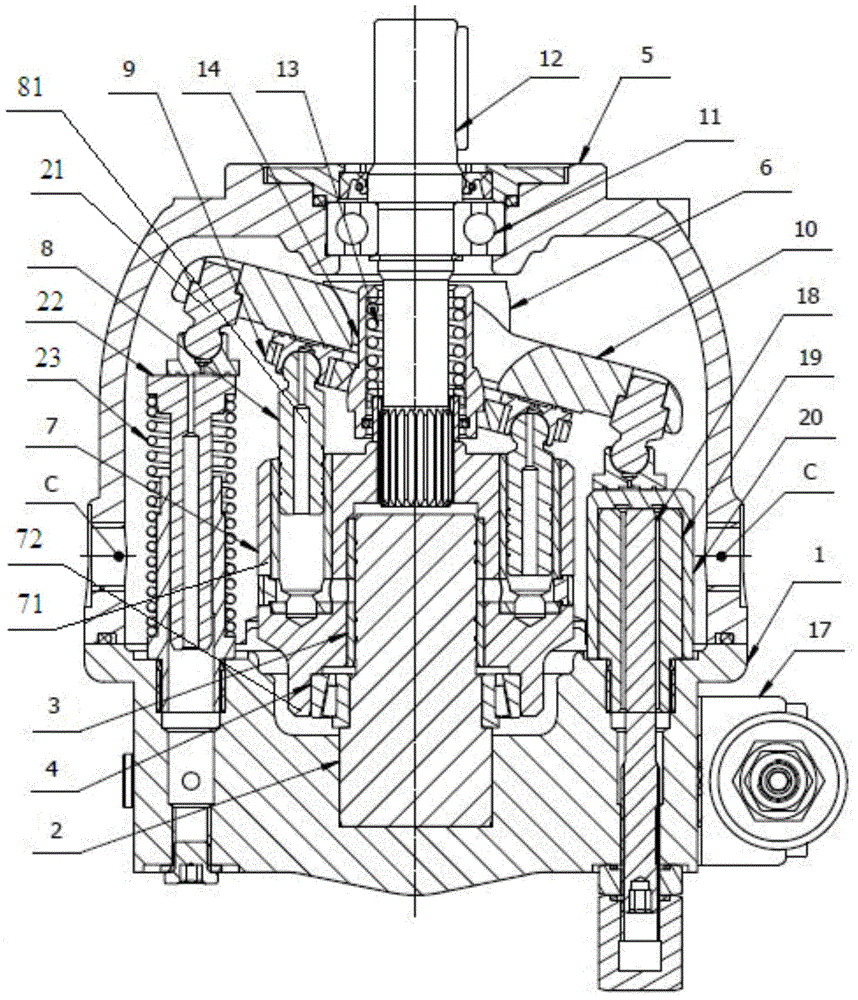

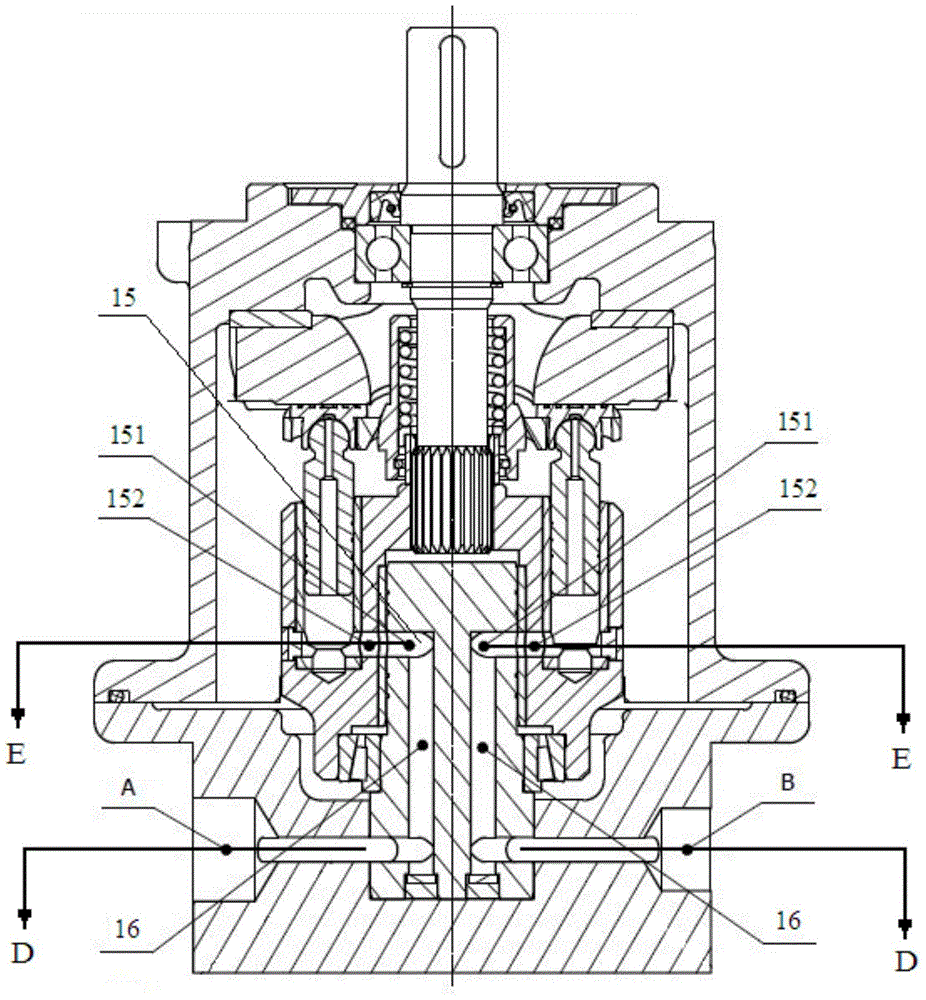

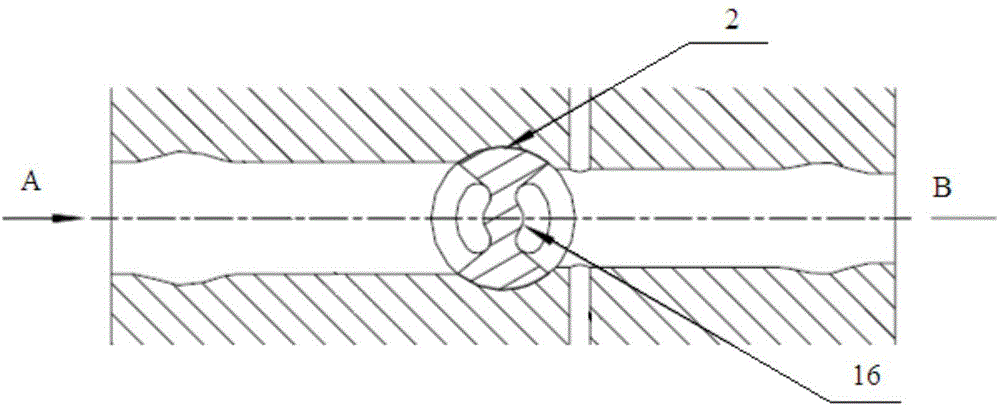

[0037] The present invention provides a variable variable axial plunger pump, the plunger pump is a radial flow distribution pump, including a drive shaft 12 driven to rotate by external force, a cylinder 7 connected to the drive shaft, a flow distribution sleeve 3, and a flow distribution shaft 2 And a variable control component that enables the plunger pump to output fluid in a variable manner; the cylinder body, the flow distribution sleeve and the flow distribution shaft are all arranged coaxially with the transmission shaft; the flow distribution sleeve is cylindrical, and the flow distribution sleeve is tightly connected to the cylinder In the cylindrical concave hole in the body; the rotation of the transmission shaft drives the cylinder body and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com