Preparation method for high-strength self-compacting concrete with recycled fine aggregate

A technology for self-compacting concrete and recycled fine aggregates, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc. It can solve the problem that the workability of self-compacting concrete is general, and the compressive strength of self-compacting concrete cannot meet the requirements of high-strength concrete. and other problems, to achieve the effect of good pumpability, wide applicability, and reduced slump loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this example, the raw materials are 42.5-grade Portland cement, fly ash, mineral powder, recycled fine aggregate with a fineness modulus of 2.2-1.6, natural fine aggregate, natural coarse aggregate, and polycarboxylic acid for efficient water reduction. agent.

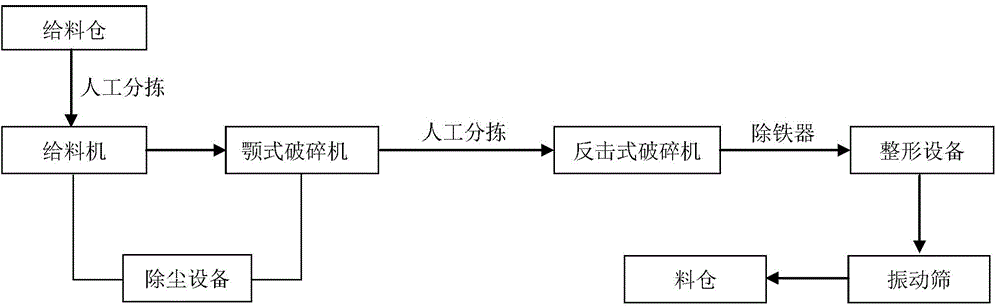

[0025] Such as figure 1 As shown, waste concrete was crushed, shaped, and sieved to obtain recycled fine aggregate particles with a particle size not greater than 4.75mm, and the water demand ratio of recycled mortar prepared from recycled fine aggregate was measured, and the saturation of recycled fine aggregate was calculated. water demand.

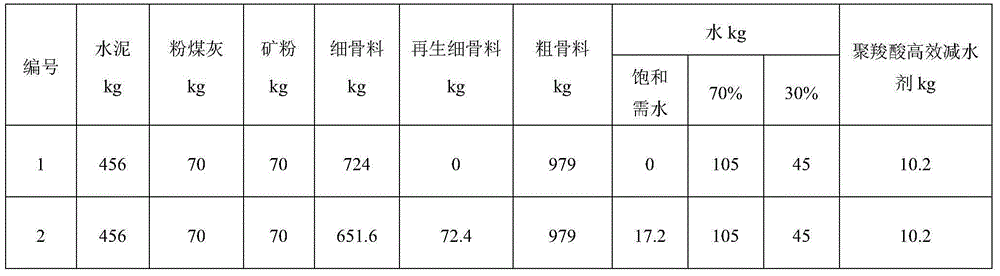

[0026] In this embodiment, the preparation method of C60 recycled fine aggregate high-strength self-compacting concrete with a water-binder ratio of 0.25 using the above-mentioned materials comprises the following steps:

[0027] Step 1: Mix and stir the regenerated fine aggregate with the required saturated water for 30 seconds. In order to prevent the regenerated f...

Embodiment 2

[0039] In this example, the raw materials are 42.5-grade Portland cement, fly ash, mineral powder, recycled fine aggregate with a fineness modulus of 2.2-1.6, natural fine aggregate, natural coarse aggregate, and polycarboxylic acid for efficient water reduction. agent.

[0040] Such as figure 1 As shown, waste concrete was crushed, shaped, and sieved to obtain recycled fine aggregate particles with a particle size not greater than 4.75mm, and the water demand ratio of recycled mortar prepared from recycled fine aggregate was measured, and the saturation of recycled fine aggregate was calculated. water demand.

[0041] In this embodiment, the preparation method of C60 recycled fine aggregate high-strength self-compacting concrete with a water-binder ratio of 0.25 using the above-mentioned materials comprises the following steps:

[0042] Step 1: Mix and stir the regenerated fine aggregate with the required saturated water for 30 seconds. In order to prevent the regenerated f...

Embodiment 3

[0054] In this example, the raw materials are 42.5-grade Portland cement, fly ash, mineral powder, recycled fine aggregate with a fineness modulus of 2.2-1.6, natural fine aggregate, natural coarse aggregate, and polycarboxylic acid for efficient water reduction. agent.

[0055] Such as figure 1 As shown, waste concrete was crushed, shaped, and sieved to obtain recycled fine aggregate particles with a particle size not greater than 4.75mm, and the water demand ratio of recycled mortar prepared from recycled fine aggregate was measured, and the saturation of recycled fine aggregate was calculated. water demand.

[0056] In this embodiment, the preparation method of C60 recycled fine aggregate high-strength self-compacting concrete with a water-binder ratio of 0.25 using the above-mentioned materials comprises the following steps:

[0057] Step 1: Mix and stir the regenerated fine aggregate with the required saturated water for 30 seconds. In order to prevent the regenerated f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com