Method for treating water-soluble polymer containing wastewater

A technology for water-soluble polymers and waste water, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of systematic research on the process parameters of water-soluble polymer waste water, Removal of low efficiency, long treatment cycle and other problems, to achieve the effect of convenient operation, pollution reduction and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

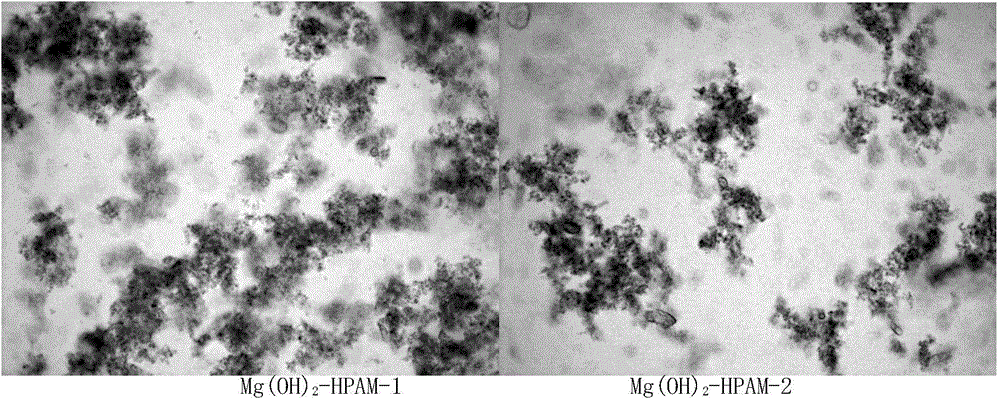

[0022] Take 1000mL of wastewater containing water-soluble HPAM, the initial concentration of HPAM is 900mg / L, and the temperature is 303K. The pH values of the system were adjusted to 8.0, 9.5, 10.5, 11.5, 12.5 and 13.5 using pH regulators. The pH regulator is one of hydrochloric acid, sodium hydroxide, calcium hydroxide and ammonia water. Add MgCl to the wastewater according to the dosage of 0.01mol / L-0.3mol / L and 0.02mol / L-0.6mol / L 2 and NaOH two reactants, maintain the oscillation speed of 150 rpm, shake for 2 hours, then centrifuge for 15 minutes, collect the supernatant, and conduct water quality analysis. against MgCl2 At different pH values, different dominant groups will appear, therefore, in the range of pH = 8.0-13.5, for MgCl 2 The dominant groups were studied. The result of practice shows that pH=9.5 is the optimum pH condition. It is determined that the removal rates of pollutants HPAM-1 and HPAM-2 can reach 98.9% and 93.9% respectively at pH=9.5, and the wa...

Embodiment 2

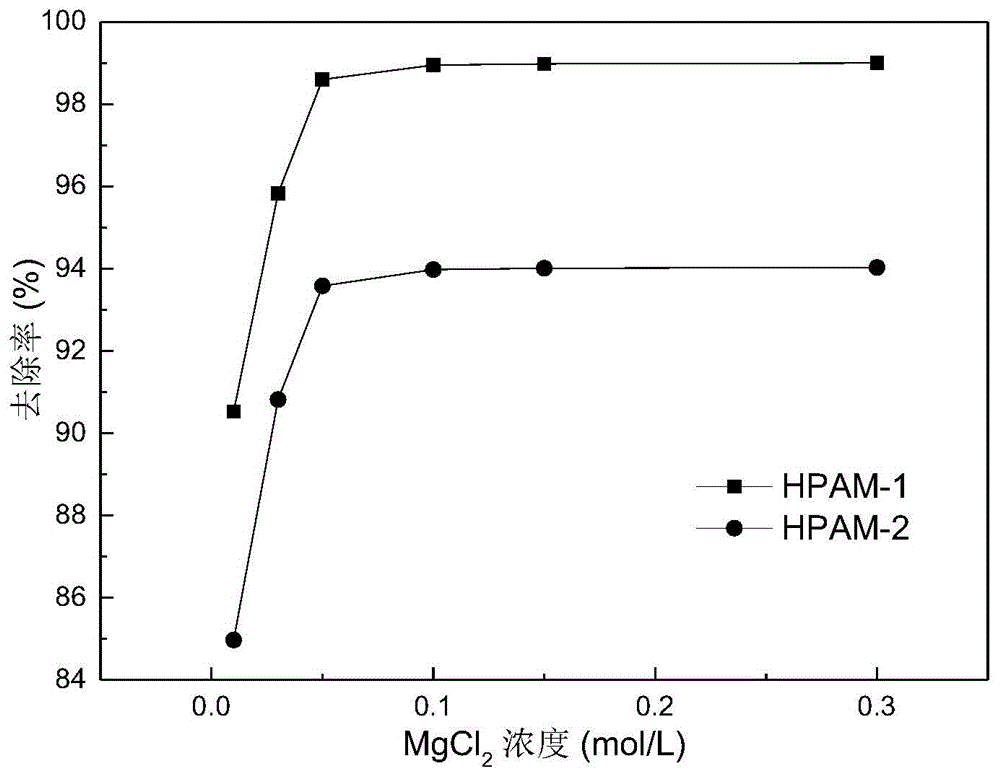

[0028] Take 1000mL of water-soluble HPAM wastewater, the pH value is 9.5, the initial concentrations of pollutants HPAM-1 and HPAM-2 are respectively 900mg / L, the temperature is controlled at 303K, and the reactant MgCl dropped into the wastewater 2 The dosages of NaOH and NaOH are 0.01mol / L-0.3mol / L and 0.02mol / L-0.6mol / L respectively; maintain the shaking speed at 160 rpm for 5 hours, then centrifuge for 10 minutes, and collect the supernatant Liquid, for water quality analysis, in the reactant MgCl 2 When the dosage reaches 0.3mol / L, the removal rates of two kinds of HPAM with different molecular weights can reach over 99% and 94% respectively, such as Figure 4 shown.

Embodiment 3

[0030] Get 1000mL of waste water containing water-soluble HPAM, the pH value is 9.5, the initial concentration of the pollutants HPAM-1 and HPAM-2 of two different molecular weights is 900mg / L, and the reactant MgCl 2 The dosage of NaOH and NaOH is 0.1mol / L and 0.2mol / L; the reaction temperature is controlled at 293K, 303K and 313K. Maintain the oscillation speed at 180 rpm and the oscillation time for 1 hour, then centrifuge for 20 minutes, collect the supernatant, and conduct water quality analysis. It is determined that the process of adsorbing HPAM from the water body is an endothermic reaction. Elevating the temperature will help Removal of HPAM. The processing results of this embodiment are shown in Figure 5(a) and Figure 5(b).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com