Hot melt cementing machine

A technology of hot-melt glue and heating plate, which is applied in book binding, binding adhesives, printing, etc., can solve the problems of non-removable transport of cardboard, non-parallel front push plates, inconvenient packaging costs, etc., and achieve Increase the effect of full integration, easy transportation, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

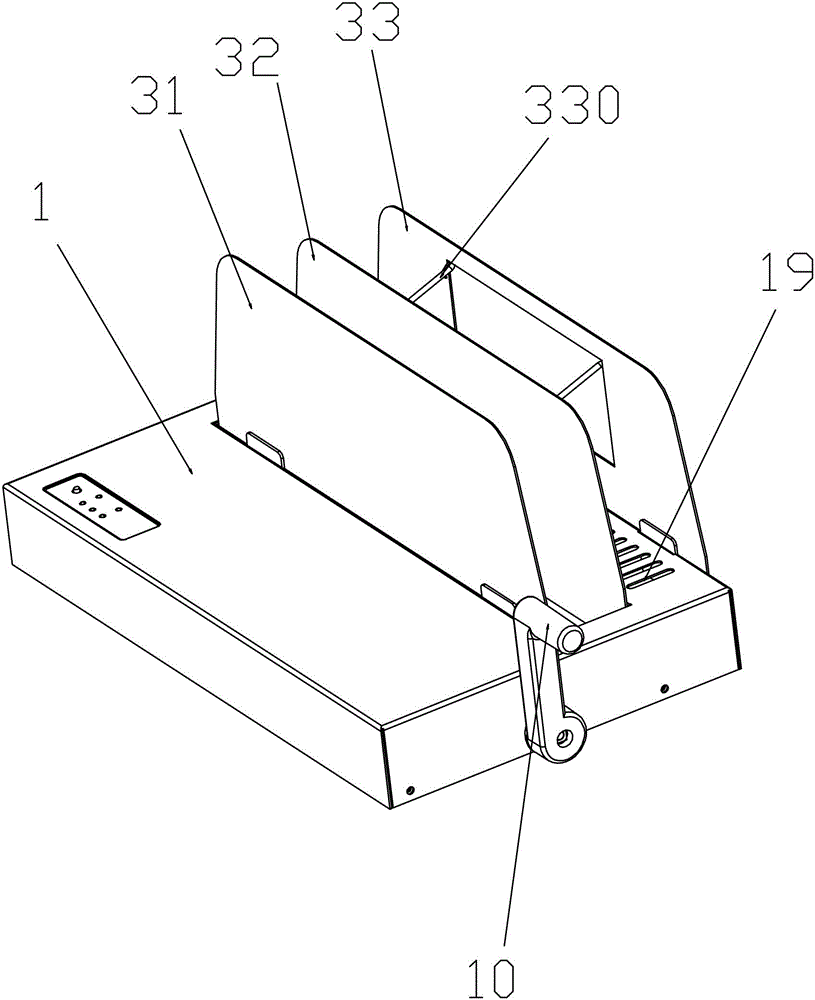

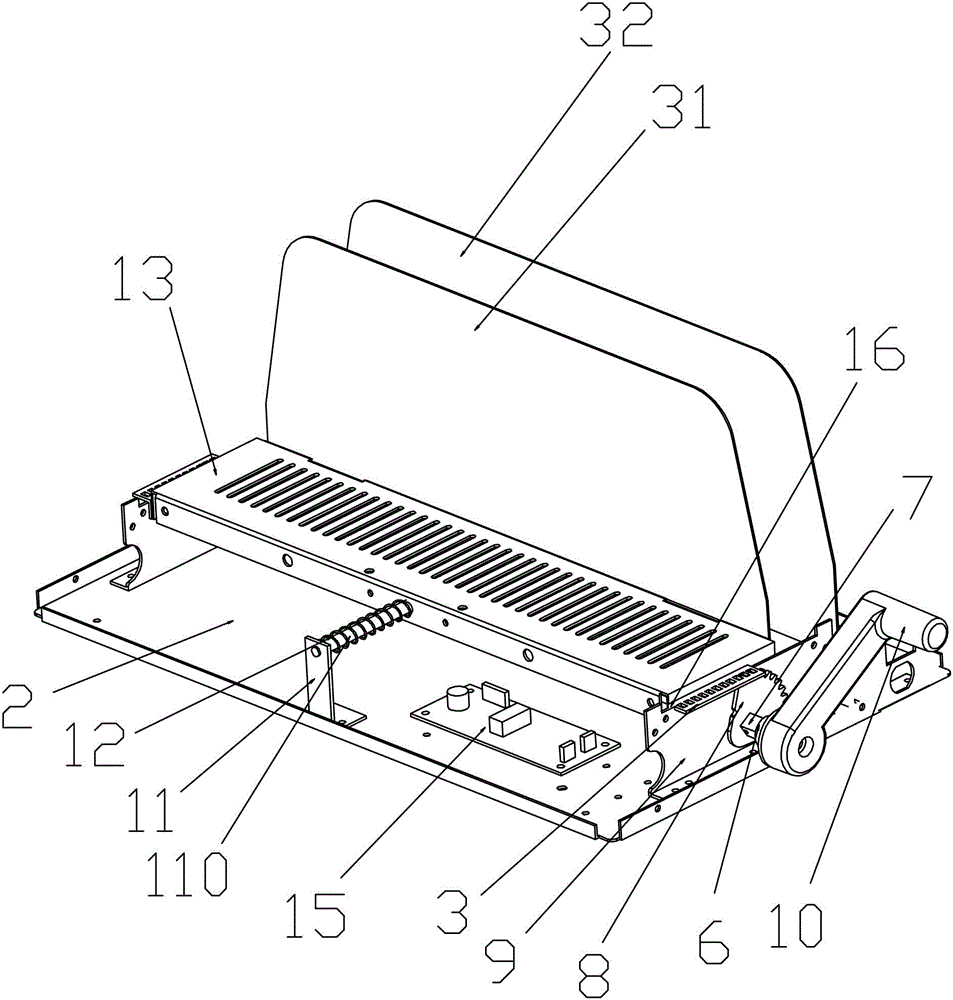

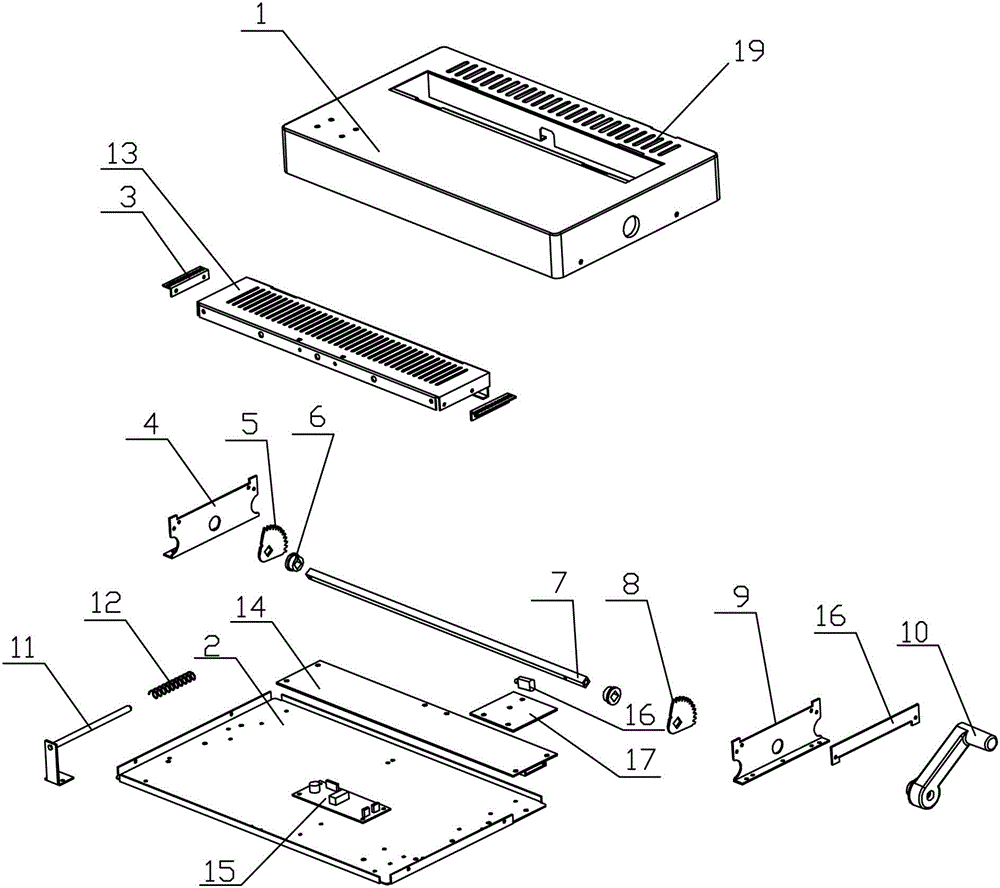

[0027] Such as Figure 1-5 As shown, the present invention discloses a hot-melt adhesive machine, which includes a housing 1, a sliding plate 13, a sliding rack 3, a left bracket 4, a left gear 5, a shaft sleeve 6, a transmission shaft 7, a right gear 8, and a right bracket 9 handle 10, spring bracket 11, spring 12, base 2, heating plate 14, controller 15, sliding rack pressing plate 16, glass fiber heat insulation board 17 and vibrator 18; wherein, the left bracket 4 and the right bracket 9 is fixedly installed on the base 2; the shaft sleeves 6 are inserted into the round holes on the left bracket 4 and the right bracket 9 respectively; the two ends of the transmission shaft 7 pass through the shaft sleeves 64 respectively, and are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com