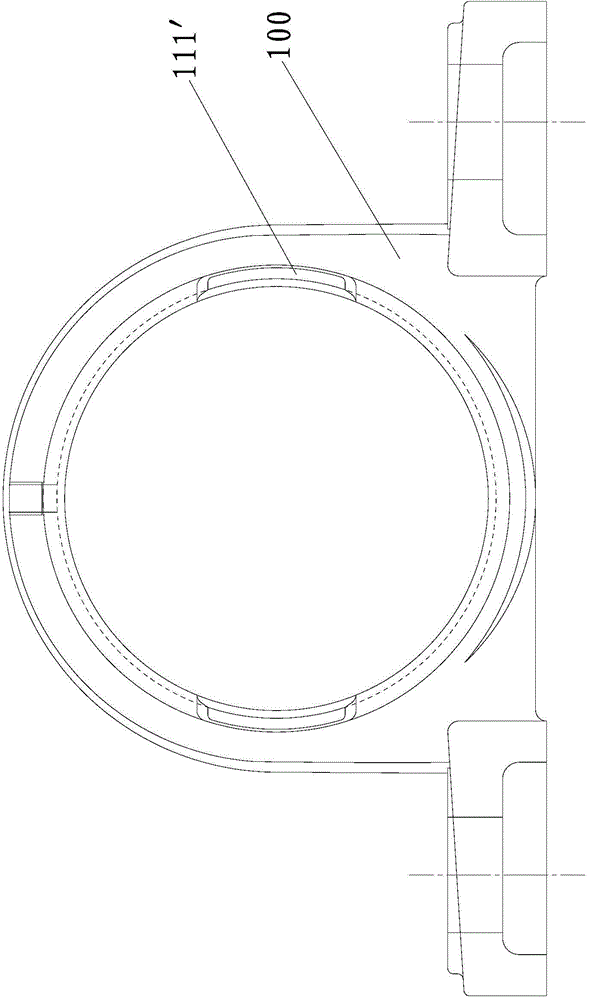

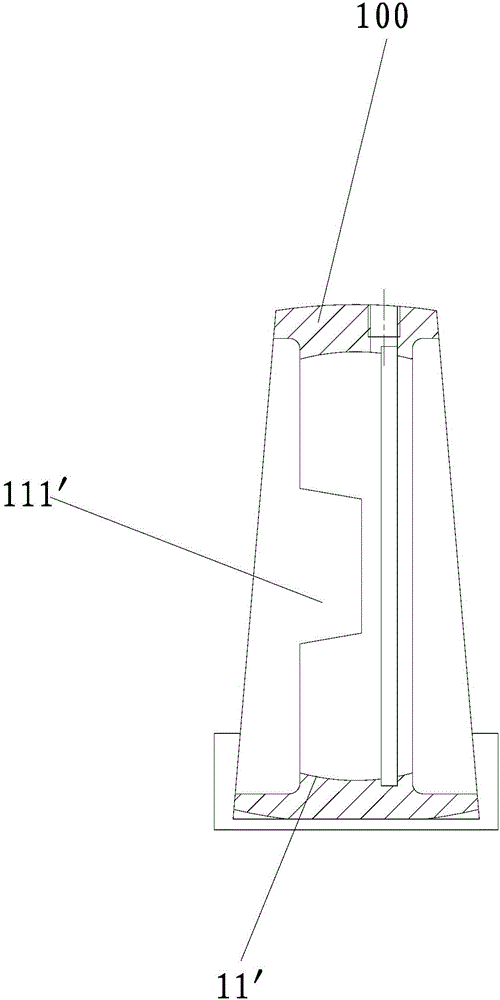

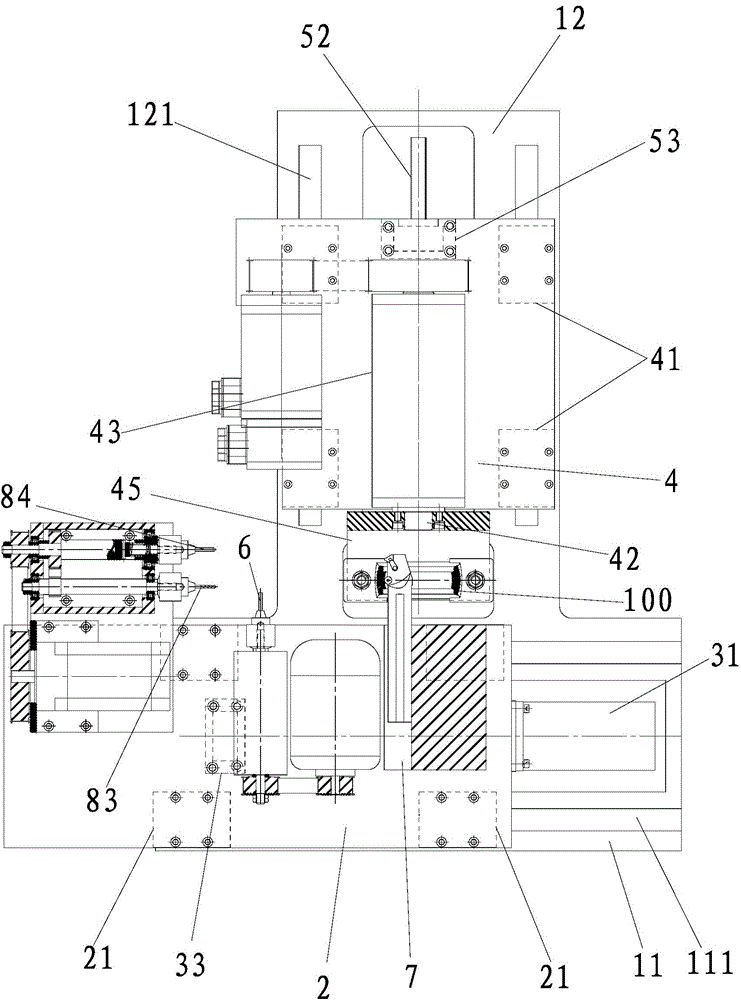

Technology for manufacturing mounted bearing pedestal and numerical control special machine tool thereof

A technology of bearings with seats and special machine tools, which is applied in the direction of manufacturing tools, other manufacturing equipment/tools, metal processing machinery parts, etc., can solve serious processing quality problems, serious quality problems, etc., achieve accuracy and quality level improvement, and reduce operating noise The effect of reducing and eliminating the shape error of the inner spherical surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0033] A process for manufacturing a bearing seat of a bearing with seat according to the present invention is mainly realized through the following steps:

[0034] 1. Cast the bearing seat blank with inner hole but no bearing insertion groove, anneal, grind the parting surface flash, and mill the installation datum surface;

[0035] 2. Perform CNC rough turning, semi-finish turning and turning oil groove on the inner spherical surface of the bearing seat blank in step 1;

[0036] 3. Carry out CNC finish turning on the inner spherical surface of the bearing seat blank in step 2 to obtain a preprocessed part, that is, use a CNC special machine tool to perform finish turning on the inner spherical surface of the bearing seat blank after semi-finishing turning;

[0037] 4. Use an end mill to mill two oppositely s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com