A multi-connected micro-reverse hydrothermal reaction kettle

A hydrothermal reaction kettle and micro-reaction chamber technology, applied in chemical/physical/physical chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as time-consuming, labor-intensive, low efficiency, etc., to improve reaction efficiency, Enhanced heat transfer capability and increased temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

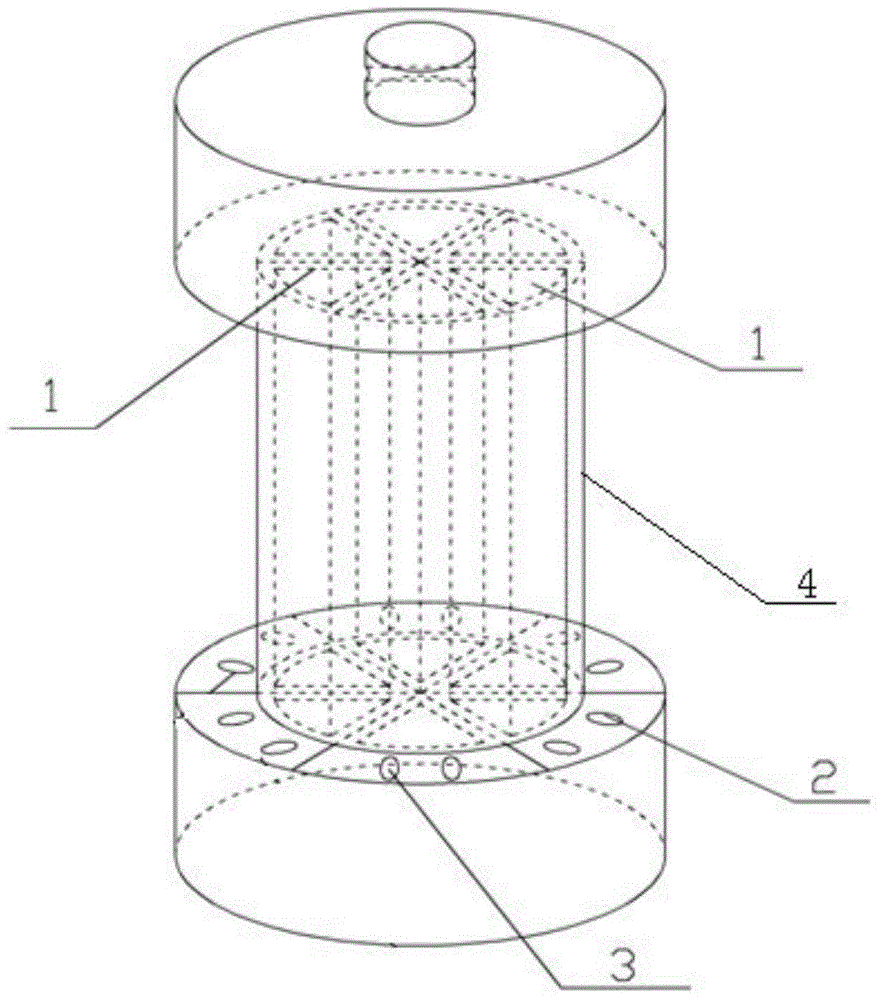

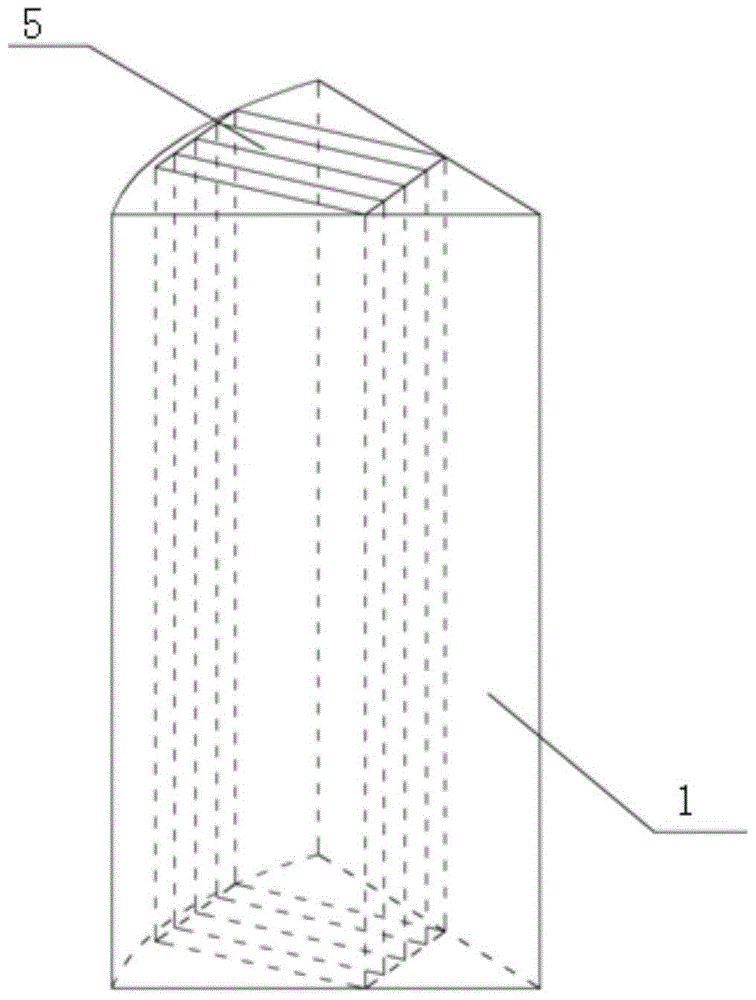

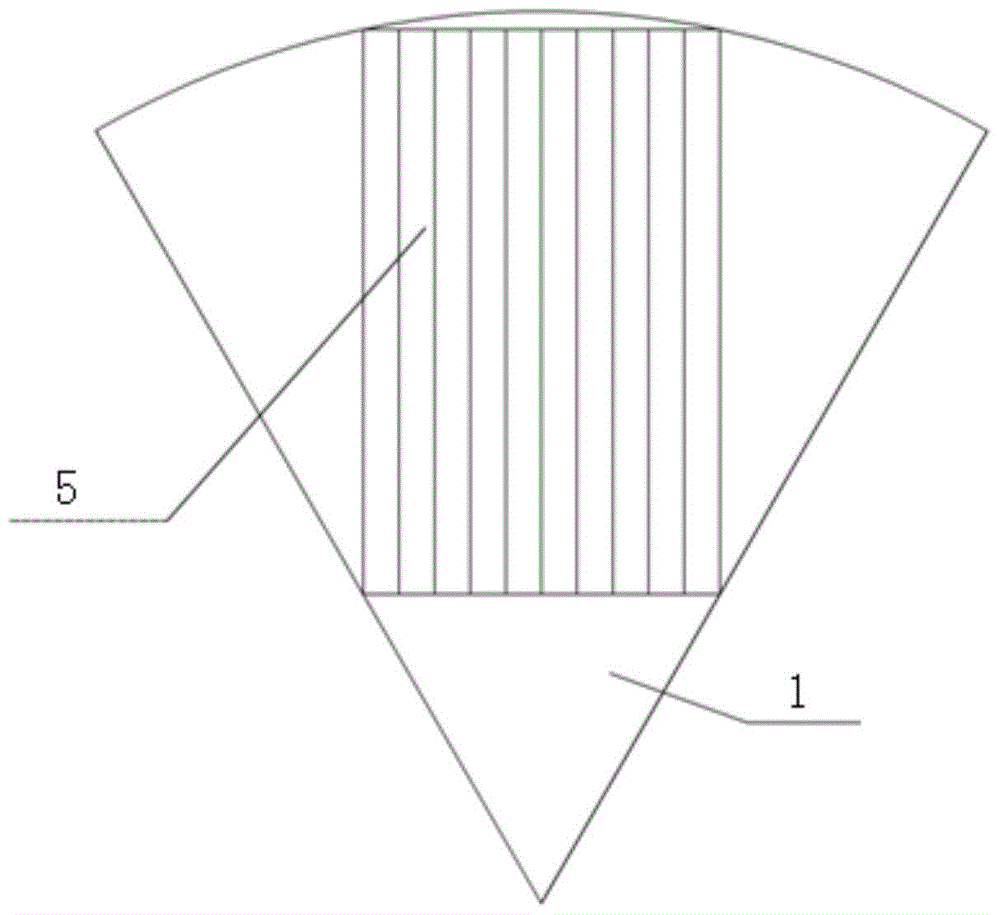

[0053] The multi-connected micro-reverse hydrothermal reaction kettle of the present embodiment includes a reaction vessel 4, in which a plurality of micro-reaction chambers 1 are arranged; in the plurality of micro-reaction chambers 1, at least one The reaction plate 5 is horizontally provided with a plurality of parallel micro-reaction channels 8 in the reaction plate 5 . Each micro-reaction channel 8 communicates with the outside of the reaction plate 5 .

[0054] The top surface of each micro-reaction channel 8 is plane, and the bottom surface thereof is wavy.

[0055] The side walls of all the micro reaction channels 8 on the reaction plate 5 are open, and the cover plate 6 is fixed on the side walls of the openings of the micro reaction channels 8 on the reaction plate 5 .

[0056] The upper part of the reaction plate 5 is provided with a feed port 9 , and the plurality of micro-reaction channels 8 communicate with the feed port 9 . A strip-shaped channel 10 is vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com