Rotational flow efficient separation silt clarifying basin and treatment technology

A clarifier and pre-sedimentation technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, separation of sediments by centrifugal force, settling tank, etc., can solve the problem of unsuitable pretreatment of sandy and micro-polluted surface water, affecting sandy rivers Problems such as utilization of water resources and waste of the effective volume of the pool body, to achieve the effect of improving pre-sedimentation efficiency, dense particle size, and reducing elevation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

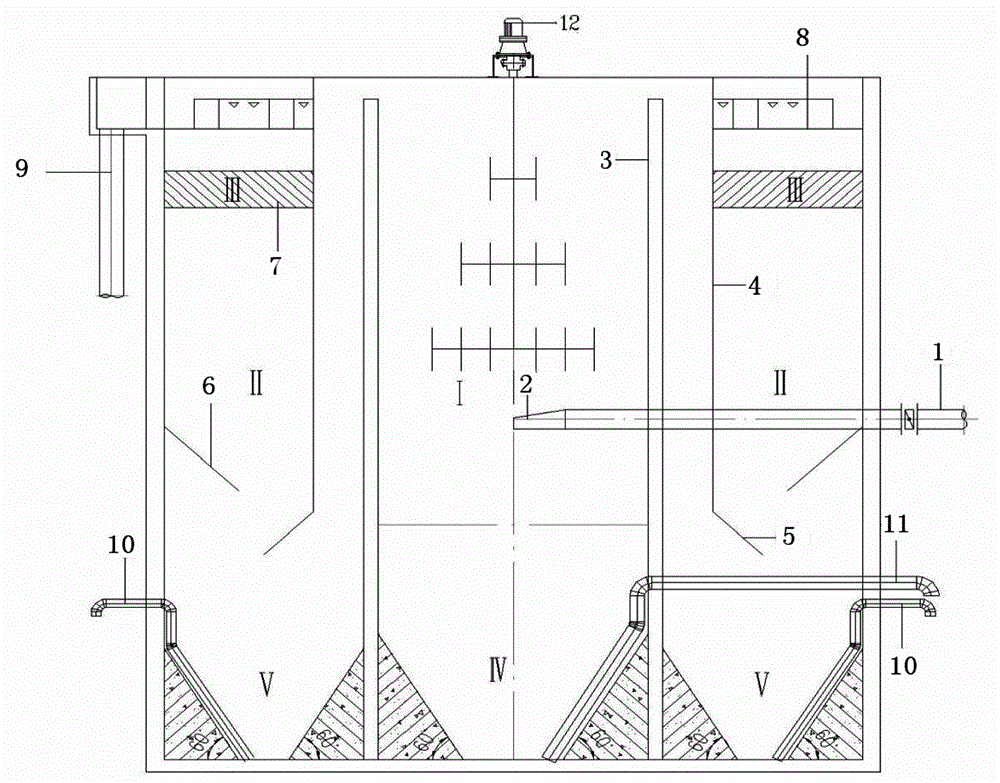

[0026] like figure 1 , figure 2 As shown, the swirl pre-settling high-efficiency separation sediment clarification tank includes a square clarifier tank, water inlet pipe 1, nozzle 2, central cylinder 3, straight deflector 4, inclined deflector 5, umbrella plate 6, and inclined pipe 7 , water collection tank 8, water outlet pipe 9, mud discharge pipe 10, central mud discharge pipe 11, mechanical swirl device 12, the inner side wall of the square clarifier is fixed with an umbrella plate 6, and the center of the square clarifier is fixed with a straight cylindrical center Cylinder 3, the square clarifier is provided with a water inlet pipe 1 extending into the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com