Heat-preserving dish structure

A technology for insulating trays and insulating bricks, which can be applied to trays, household utensils, table utensils, etc., and can solve problems such as inconsistent work and rest time, and the completion of meals after a long wait

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below according to the drawings and embodiments.

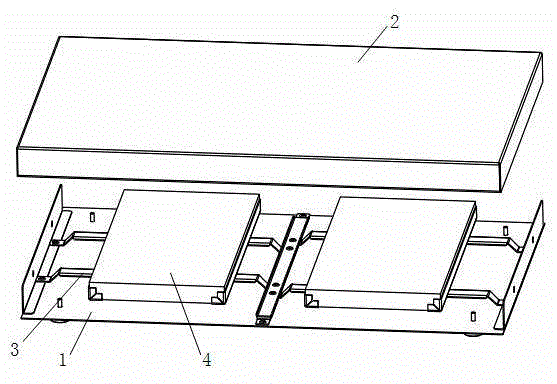

[0011] Such as figure 1 As shown, a heat preservation tray structure described in the embodiment of the present invention includes a base 1 and a heat preservation tray 2 airtightly fastened on the base 1, the base 1 is provided with a bracket 3, and the bracket 3 is fixed A thermal insulation brick 4 is installed, and the thermal insulation brick 4 is embedded with an electric heating wire that can be energized to generate heat. The top plane of the thermal insulation brick 4 is attached to the thermal insulation plate 2 .

[0012] The bottom of the heat preservation tray is pasted with two heat preservation bricks. The bracket is fixedly installed on the base by bolts.

[0013] The electric heating wire is energized to generate heat, and the heat is transferred to the insulation brick. Due to the low thermal conductivity of the insulation brick, the heat is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com