Self-adaptive coal quality adjustment system and method in RUNBACK (RB) process

A self-adaptive adjustment and auxiliary machine failure technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the calculation deviation of calorific value correction circuit, large fluctuations in fuel volume, and the quality of combustion control system reduce problems, achieve the effect of improving quality, maintaining stability, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

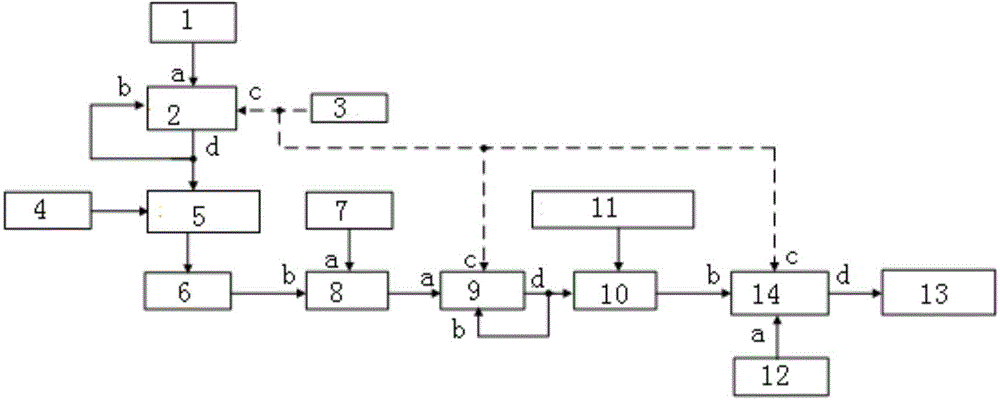

[0029] Coal quality self-adaptive adjustment system during auxiliary machine failure load reduction process, including: calorific value correction module 1, first switcher 2, RB generation module 3, actual coal quantity module 4, first multiplier 5, corrected coal quantity module 6 , unit load module 7, divider 8, second switcher 9, second multiplier 10, target load module 11 when RB occurs, third switcher 14, coal quantity instruction module 12, fuel controller module 13.

[0030] Among them, the calorific value correction module 1 is a correction coefficient of 0.8-1.2; the first switcher 2, the second switcher 9, and the third switcher 14 have four pins respectively, and pins a and b are input analog quantities channel, pin c is the trigger condition and receives digital signals, pin d is the analog output channel, when pin c is a logic true signal, pin b is on, and pin c i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com