A Method for Measuring Solid Surface Free Energy Using Adsorption

A solid surface, adsorption capacity technology, applied in measurement devices, surface/boundary effects, instruments, etc., can solve problems such as complexity, difficulty in surface energy testing, uneven surface of aggregates, etc., to achieve simple implementation steps, fast and effective water damage Performance evaluation, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

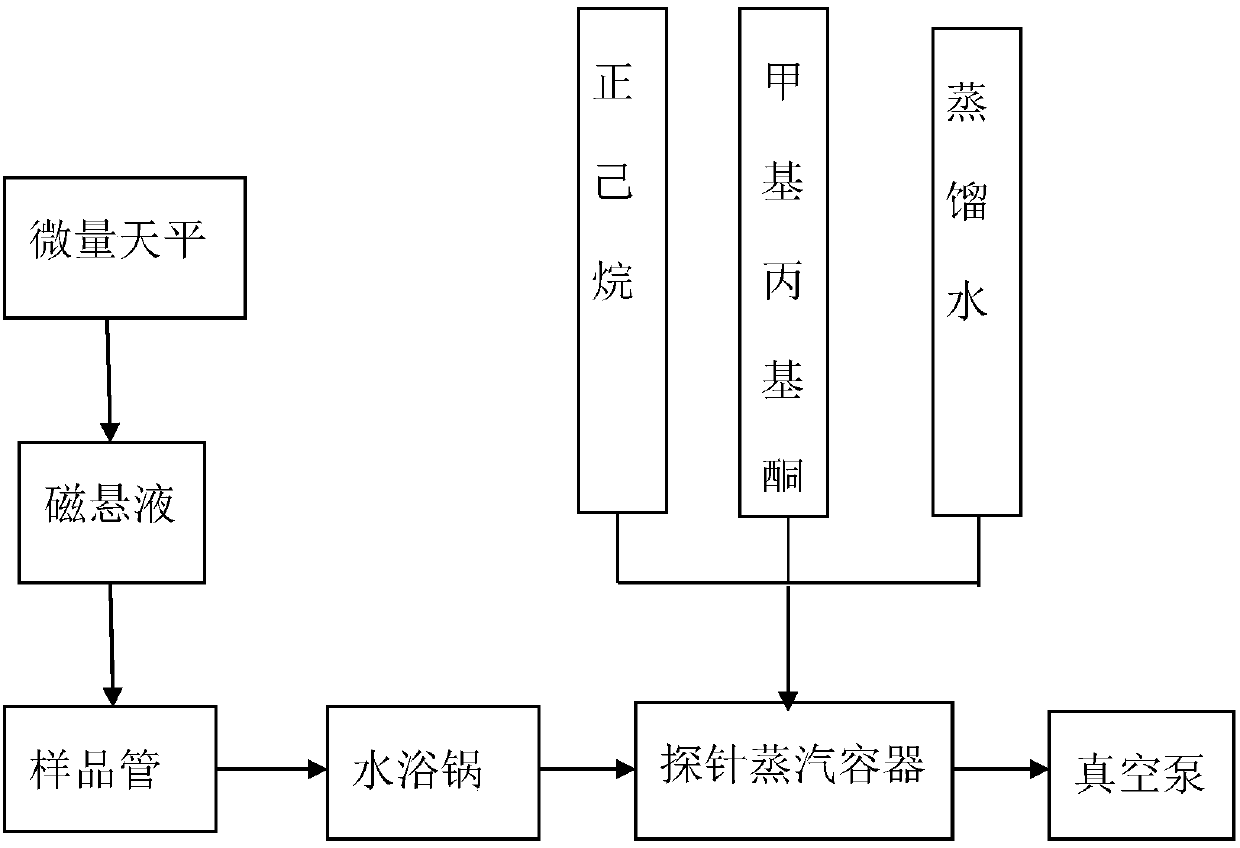

Method used

Image

Examples

Embodiment Construction

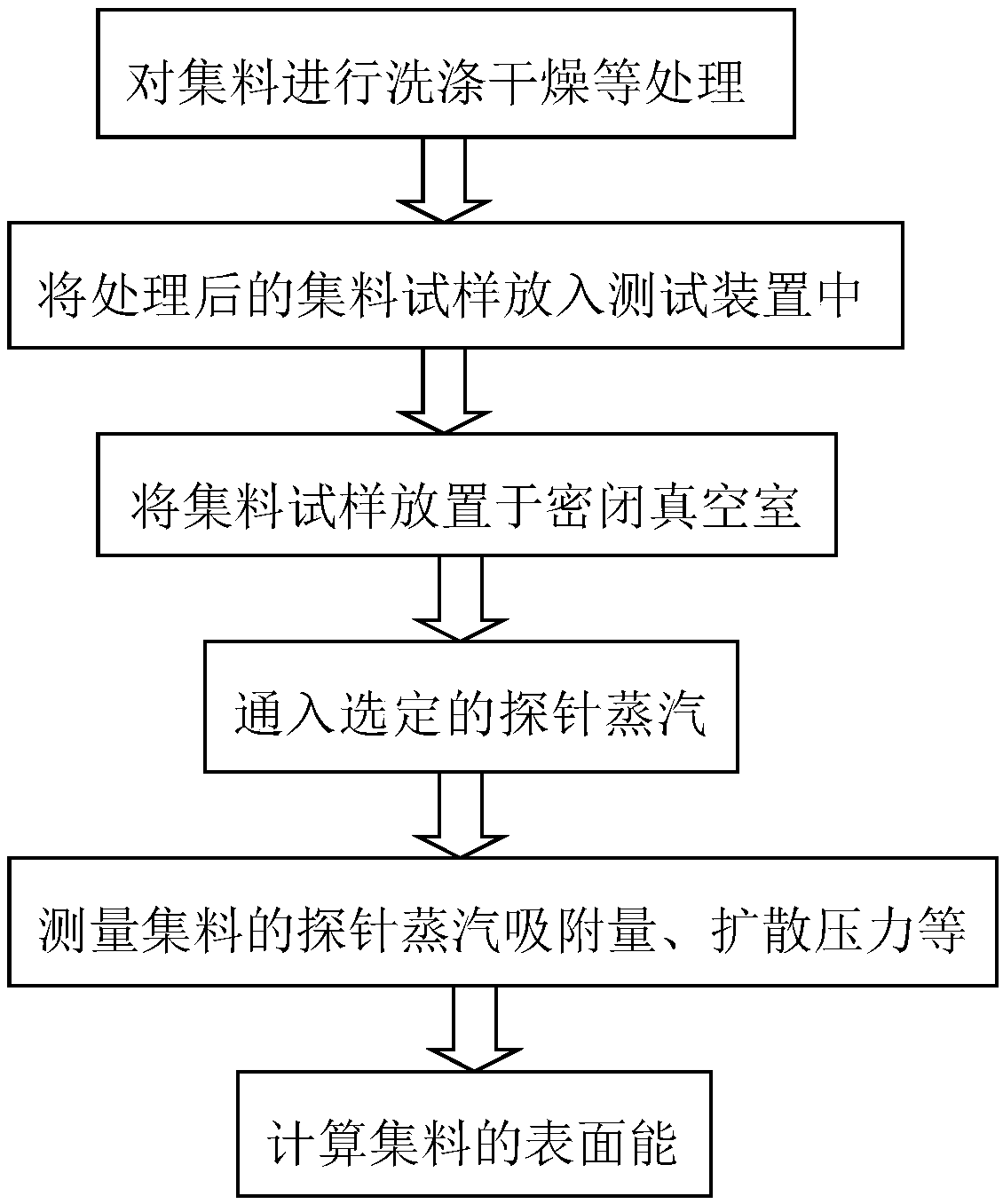

[0030] A method for measuring solid surface free energy by adsorption, comprising the steps of:

[0031] 1) After preparing the sample, place it in a sealed vacuum chamber. The vacuum chamber maintains a constant temperature of 25°C. The specific steps include: the sample is screened and the particle size is between 4.75mm-2.36mm, and then washed Cycle, the washing cycle includes first washing with distilled water, methanol and n-hexane in sequence, then washing with methanol again, drying in an oven at 150°C for 8 hours after the final washing, and drying at room temperature for at least 8 hours. ;

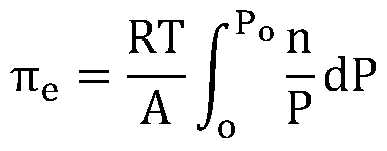

[0032] 2) The probe steam is released into the vacuum chamber, and the vacuum chamber maintains a constant temperature. The probe steam reaches the saturated vapor pressure P at different stages (that is, the time period divided by a certain time interval after the probe gas is introduced). o When measuring the probe vapor adsorption amount n on the surface of the sample at diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com