Determination method for predicting material uniaxial constitutive relation through circular ring radial compression energy

A constitutive relation, radial compression technology, applied in the application of stable tension/compression to test the strength of materials, special data processing applications, instruments, etc. Problems such as easy acquisition of axis constitutive relation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

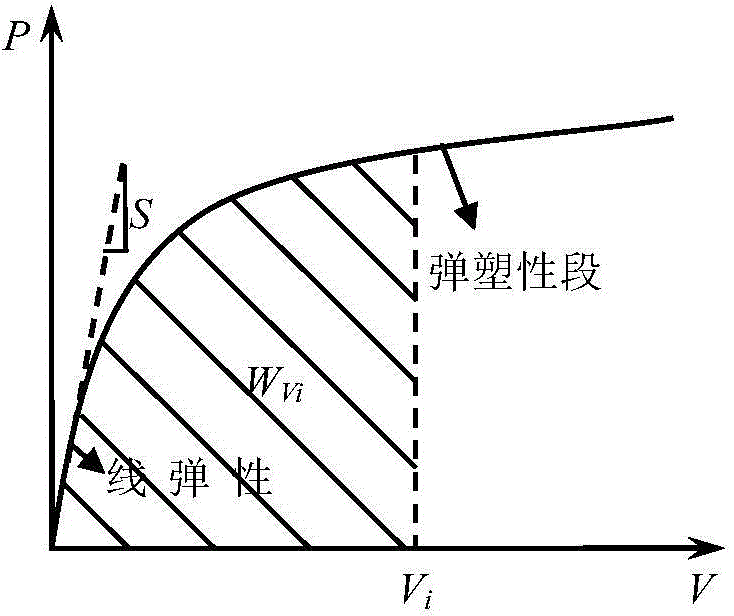

[0055] In the technical solution of the present invention, based on the theoretical derivation of compressive deformation energy of the Mises strain energy criterion and the calibration of finite element parameters, the present invention proposes a technical theoretical system for predicting the uniaxial constitutive relationship of materials by using the radial compressive deformation energy of circular minimally invasive sliced samples .

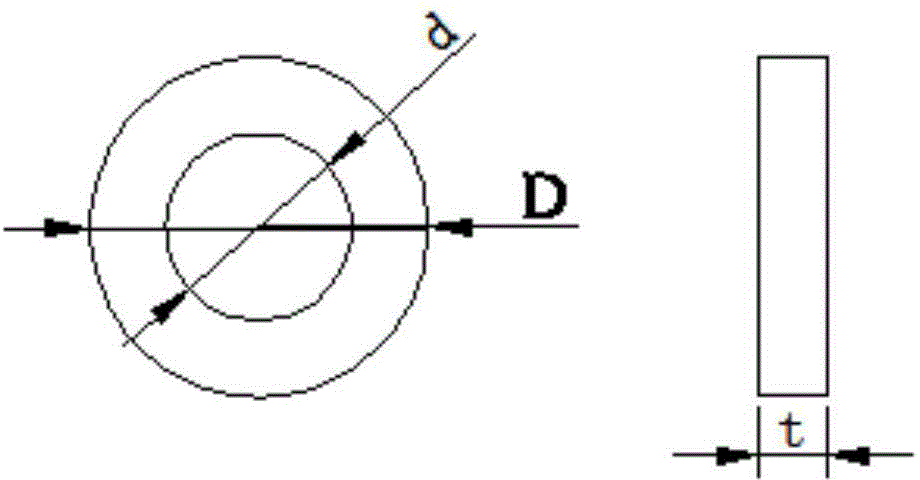

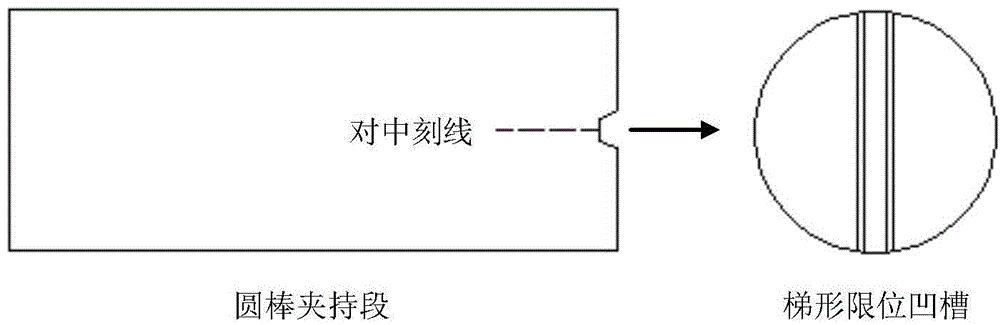

[0056] A radial compression test was carried out on the annular slice of the A-type nuclear fuel zirconium alloy cladding tube by using a flat indenter with a groove, and the uniaxial constitutive relation curve was obtained. Figure 4 The load-displacement curve per unit thickness obtained from the radial compression test of the ring sliced specimen (outer radius R is 5mm, inner and outer diameter ratio μ is 0.8) is given. The data processing flow is as follows: firstly, the initial linear elastic section data is extracted from the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com