Packaging online-testing device and method for spiral sampling

A helical sampling and packaging machine technology, applied in measurement devices, sampling devices, particle and sedimentation analysis, etc., can solve problems such as large parameter differences, insufficient sealing of lids, easy to be cheated, etc., to ensure consistency and avoid replacement. fake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

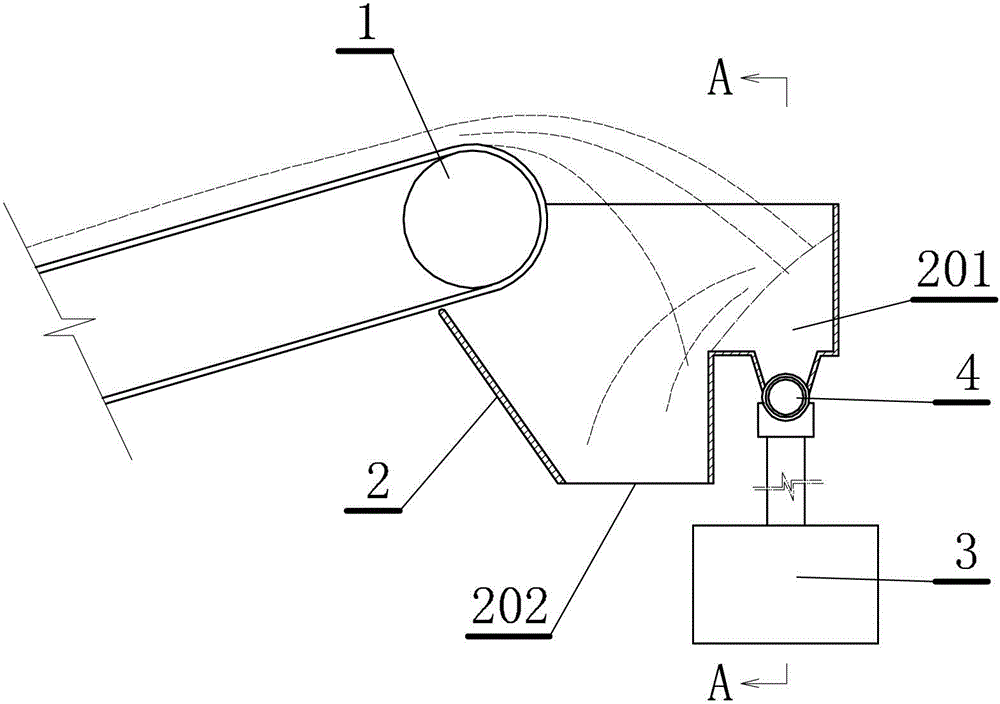

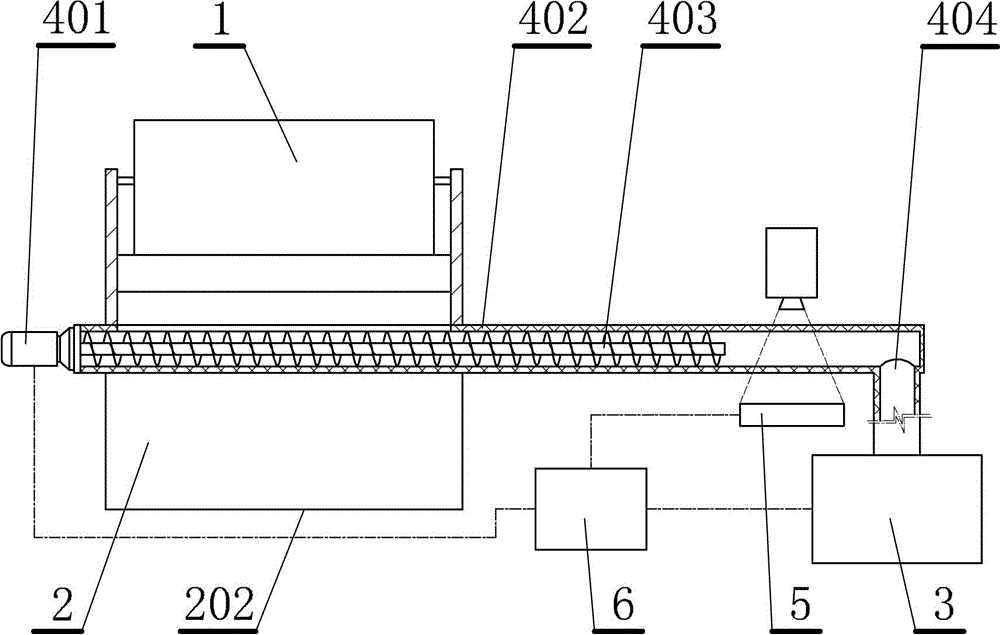

[0026] This embodiment is a device for spiral sampling on-line detection package, such as figure 1 , 2 shown. The present embodiment comprises: the material receiving bucket 2 that is installed in front of the belt machine head 1, the described material receiving bucket is provided with a sampling groove 201, and the inlet of the described sampling groove is connected with the screw sampler 4, and the described screw sampler A radiation detector 5 is provided on the top, and the outlet of the spiral sampler is connected to the sample packaging machine 3 through a pipeline, and the spiral sampler, radiation detector and sample packaging machine are electrically connected to the sampling controller 6 ( figure 2 The electrical connection is indicated by a dash-dotted line).

[0027] The sampling method in this embodiment is a method of sampling at the head of the belt conveyor, that is, collecting the materials thrown out by the belt conveyor at the head of the belt conveyor. ...

Embodiment 2

[0035] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment about the sampling groove. The horizontal projection of the sampling tank described in this embodiment is a rectangle, the long side of the rectangle is parallel to the axis of the pulley of the belt conveyor, and the bottom of the sampling tank is open to the spiral sampler.

[0036] It is called a "trough" to express its function of holding materials. It does not have the characteristic shape of a general "trough" with a concave bottom in the middle and sides on both sides, but a long strip with a roughly triangular cross-section. In other words, it is a "trough" with one groove side removed and only the bottom and one side of the groove. When sampling, the material is accumulated in the triangular area formed by the bottom of the tank and a side of the tank. When the material on the sampling tank is accumulated to a certain extent, the material will fall naturally d...

Embodiment 3

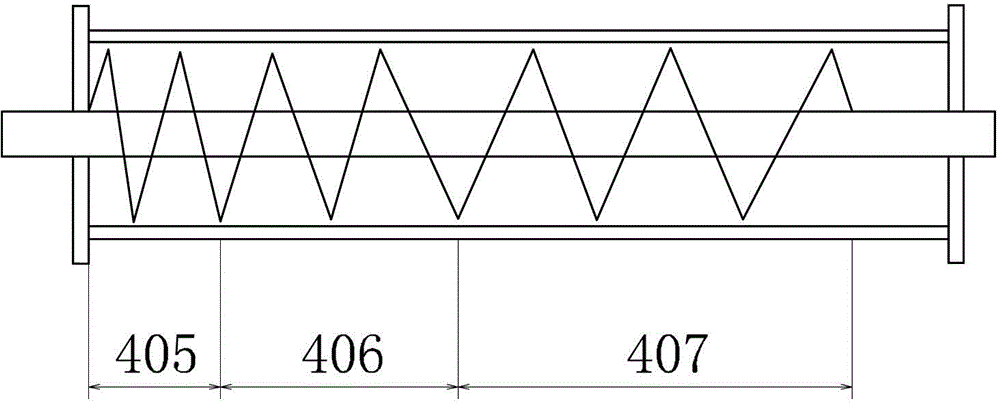

[0040] This embodiment is an improvement of the above embodiment, and is a refinement of the above embodiment about the spiral sampler. The spiral sampler described in this embodiment includes: a sampling barrel 402, in which a screw push rod 403 driven by a motor 401 is provided, and one end of the sampling barrel is provided with a sampling port as the outlet of the spiral sampler. Output port 404, such as figure 2 shown.

[0041] A spiral sampler is arranged at the bottom of the sampling tank. The rotary push rod of the spiral sampler is consistent with the long direction of the sampling slot, see figure 2 , the bottom of the sampling tank is open to the auger sampler, that is to say, if the auger pusher of the auger sampler does not rotate, the material accumulates on the auger pusher of the auger sampler. The screw push rod is a rotating rod driven by a motor, on which a helical blade is arranged, and the outer circumference of the blade is surrounded by a cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com