Oil gas type load reduction pneumatic actuator cylinder and load reduction method thereof

An oil-pneumatic and actuator technology, which is applied to fluid pressure actuators, servo motors, chassis, etc., can solve problems such as increased product weight, blockage, and large buffer pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

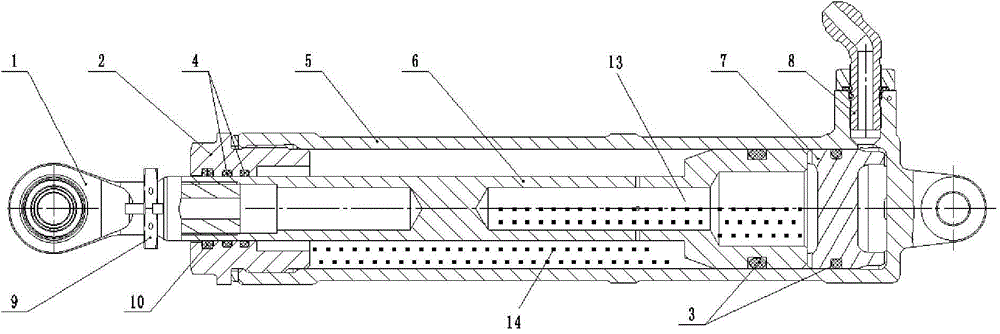

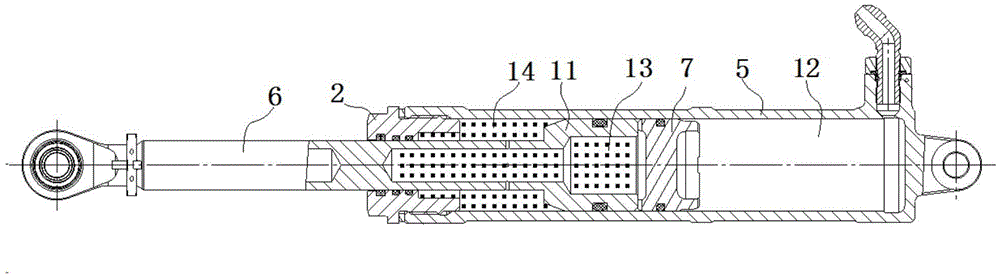

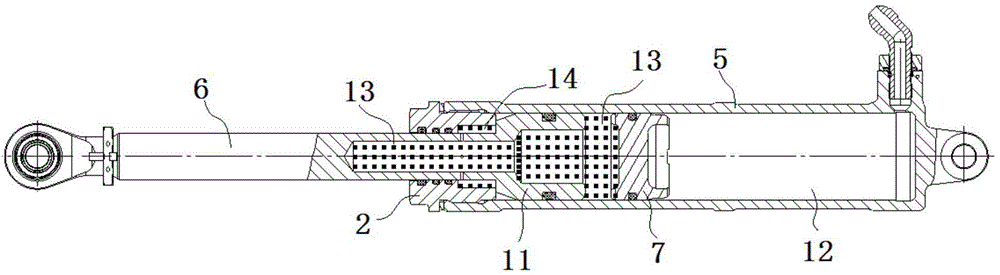

[0024] An oil-pneumatic degradable pneumatic cylinder, such as figure 1 As shown, it is mainly composed of an outer cylinder 5, a piston rod 6, a floating piston 7, an earring joint 1, an end cover 2, a sealing ring, a pipe joint and the like. The floating piston is installed between the closed end of the outer cylinder 5 and the fixed piston 11 of the piston rod 6; the end cover 2 is connected with the outer cylinder 5 through threads, and the end cover 2 and the The fixed piston 11 forms a closed chamber composed of a rod chamber 14 and a rodless chamber 13; the closed chamber is filled with hydraulic oil, and the total amount of hydraulic oil is the closed chamber in this state when the piston rod is fully extended. .

[0025] In order for the piston rod of the actuator to become a differential actuator at the end of the actuator, a certain volume of hydraulic oil is filled between the floating piston 7 and the end cover; the amount of hydraulic oil depends on the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com