Hollow sodium filled valve based on cross wedge rolled billet

A hollow and valve technology, applied in valve devices, machines/engines, mechanical equipment, etc., can solve the problems of low material utilization rate, difficult temperature and quality control, and many processes, so as to improve the cooling effect, realize light weight and shape. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

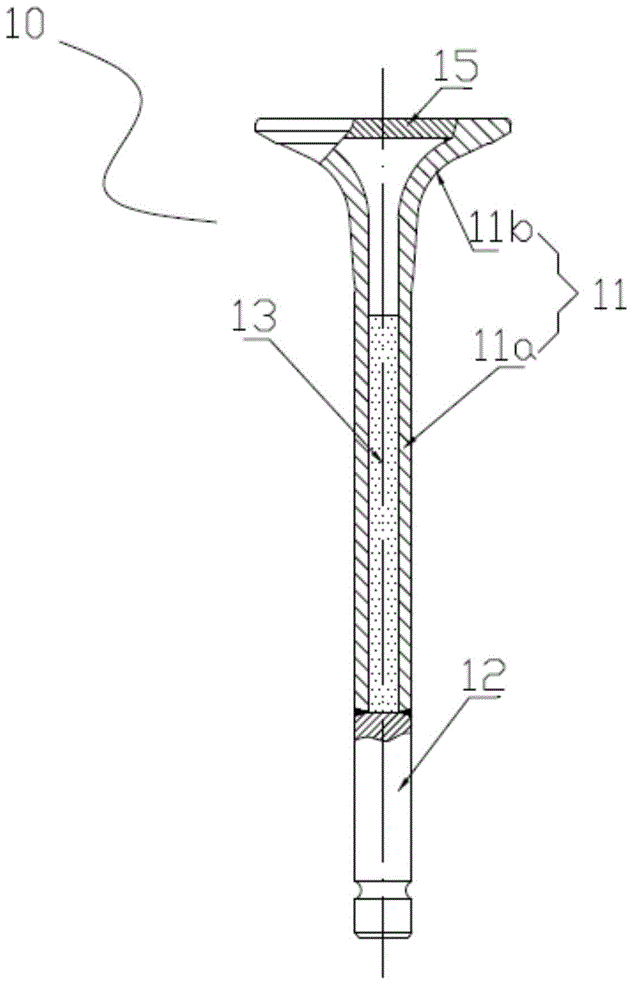

[0021] see figure 1 , which is a structural schematic diagram of the hollow sodium-filled valve described in the present invention.

[0022] A hollow sodium-filled valve 10 based on a cross wedge rolled billet of the present invention includes a valve housing 11, a solid rod portion 12 and a disc end face plug 15; the valve housing 11 includes an integrally formed trumpet-shaped hollow disc portion 11b and a hollow rod part 11a, one end of the hollow rod part 11a of the valve housing 11 is welded to the solid rod part 12, and the cross-sectional diameter of the solid rod part 12 is the same as the outer diameter of the cross-sectional cross-section of the hollow rod part 11a; The disk end face plug 15 is welded to the opening of the hollow disk part 11b to seal the hollow disk part 11b and form an inner cavity with the valve housing 11; the inner cavity is filled with metal sodium 13.

[0023] Further, the outer surfaces of the hollow rod portion 11 a and the solid rod portio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com