A frequency continuously adjustable mass damper

A mass damper and frequency technology, applied in bridge parts, building components, bridges, etc., can solve the problems of difficult to accurately manufacture spring stiffness, excessive comfort, limited tunable range, etc., achieve huge economic and social benefits, reduce Small high-frequency vibration, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

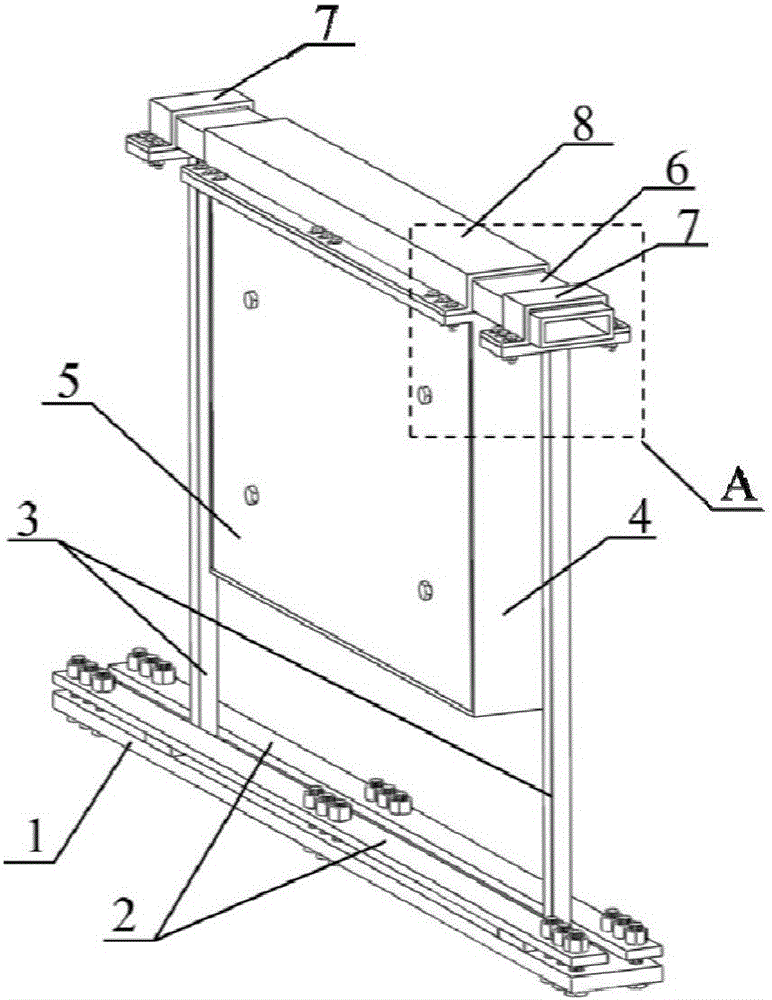

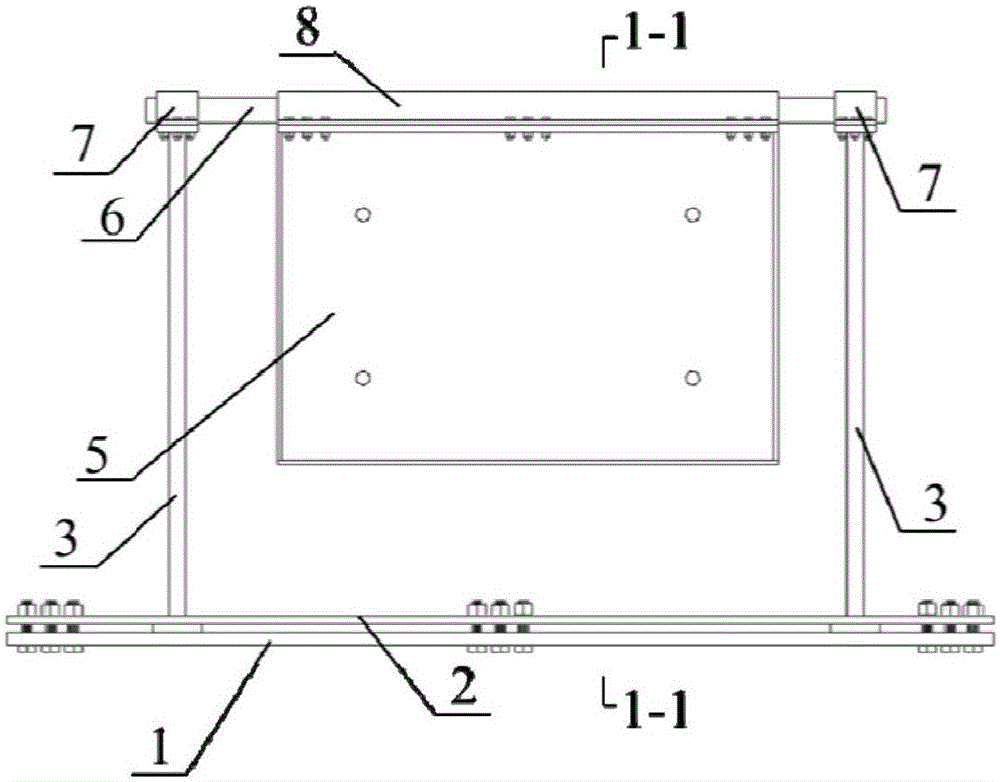

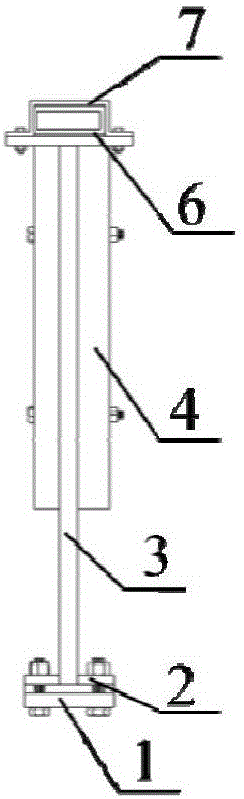

[0020] A frequency continuously adjustable mass damper comprises a bottom plate 1, a pressure plate 2, a column 3, a counterweight box 4, a counterweight steel plate 5 and a beam 6.

[0021] The overall schematic diagram, elevation and sectional view of the present invention are as follows: Figure 1-Figure 4 shown. Column 3 such as Figure 6 As shown, a rectangular column foot is set at the bottom, and a rectangular column cap is set at the top. The bolt I11 is pre-embedded or implanted into the structure where the damper needs to be installed, and the column foot of the column 3 is clamped and fixed between the bottom plate 1 and the pressure plate 2 by tightening the bolt I11. Before the upright is clamped and fixed, the foot of the upright 3 can move in the length direction of the bottom plate 1, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com