A transmission system torsional vibration damping method and its application

A technology of transmission system and torsional vibration reduction, which is applied in the field of mechanical vibration reduction, can solve the problems of inconvenient repair of the vibration reduction structure in the later stage, and achieve the effects of small torsional fatigue load, stable operation and reduced vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

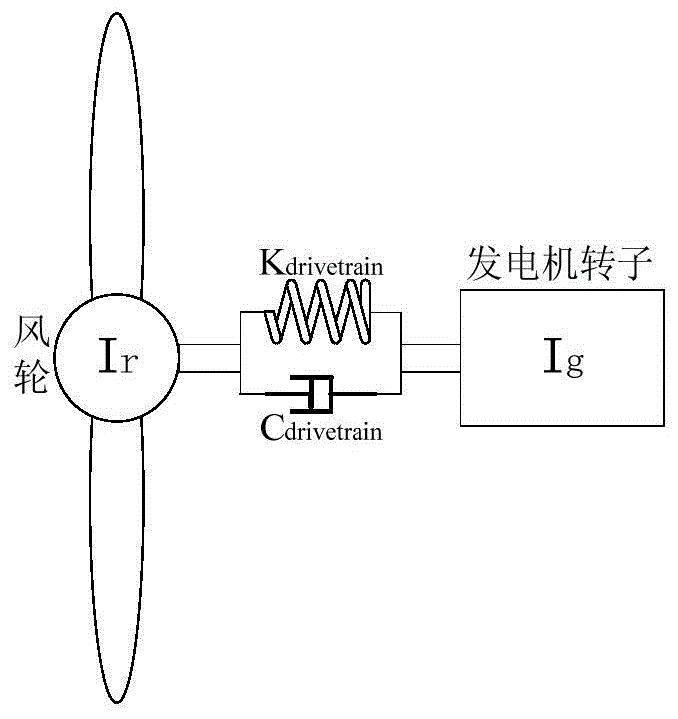

[0028] The present invention provides a torsional vibration damping method for a transmission system, which is mainly to add a torsional vibration damper in a parallel connection to the transmission system to reduce vibration at a specific modal frequency in the torsion direction. The effect is significant, and the parallel connection is not Changing the original transmission system structure can be used to repair abnormal vibration afterwards.

[0029] The mechanics principle of this technical solution is to tune the moment of inertia vibration reduction, that is, connect the tuning moment of inertia damper (including moment of inertia block, spring and damping unit) to the transmission system, and control the vibration mode resonance of the moment of inertia block and the transmission system The torsional vibration energy of the transmission system is transferred to the tuned moment of inertia damper, thereby suppressing the torsional vibration of the transmission system.

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com