Bacteria slag type coal dust suppressant and preparation method thereof

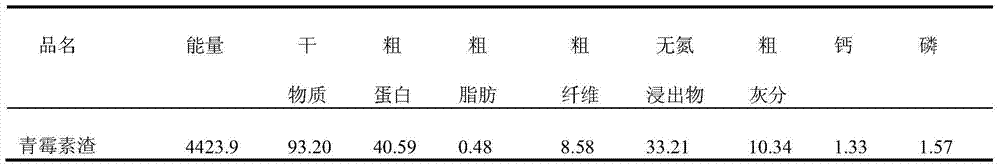

A technology of dust suppressant and coal is applied in the field of preparation of starch polyvinyl alcohol type coal dust suppressant, which can solve the problems of antibiotic residues, soil and water pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

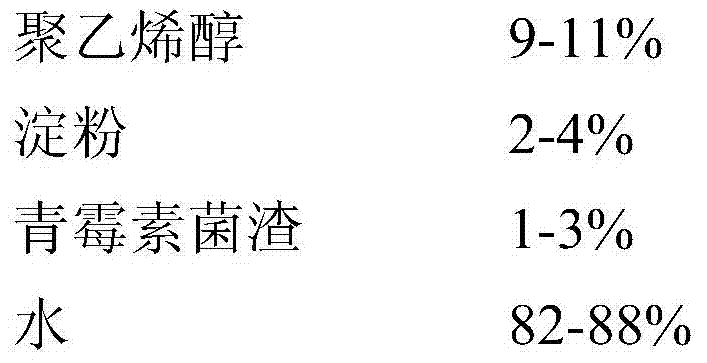

Embodiment 1

[0018] When 10% polyvinyl alcohol + 3% starch + 2% penicillin residue + 85% water, the dust suppressant (1) has a moderate viscosity of 345mPa·s; (2) the initial stratification time can reach 135h; (3 ) The cured layer has good film-forming properties and water resistance, and can resist certain environmental changes. The penetration speed of the dust suppressant is 0.24mm.s -1 , the compressive strength is 225KPa, the wind erosion resistance is 0.58%, the compressive strength after freezing and thawing of the solidified layer is 205KPa, and the compressive strength after raining is 216KPa.

Embodiment 2

[0020] When 9% polyvinyl alcohol + 2% starch + 88% water + 1% penicillin fungus residue, the dust suppressant (1) viscosity at this moment is reduced to 220mPa·s; (2) the initial stratification time can reach 149h; ( 3) The cured layer has good film-forming properties and water resistance, and can resist certain environmental changes. The penetration speed of the dust suppressant is 0.19mm.s -1 , the compressive strength is 198KPa, the wind erosion resistance is 0.75%, the compressive strength of the solidified layer is 173KPa after freezing and thawing, and the compressive strength after raining is 186KPa.

Embodiment 3

[0022] When 11% polyvinyl alcohol + 4% starch + 3% penicillin scum + 82% water, the viscosity of the dust suppressant (1) becomes high at this moment, which is 520mPa·s; (2) the initial delamination time is reduced to 79h; ( 3) The cured layer has good film-forming properties and water resistance, and can resist certain environmental changes. The penetration speed of the dust suppressant is 0.15mm.s -1 , the compressive strength is 210KPa, the wind erosion resistance is 0.62%, the compressive strength of the solidified layer is 186KPa after freezing and thawing, and the compressive strength after raining is 190KPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com