Polyurethane mop sponge and production method thereof

A polyurethane and mop technology, applied in the field of polyurethane products, can solve the problems of perishability, dirty water pressure out, mop is not easy to clean, etc., and achieve the effect of not easy to tear, easy to clean, and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

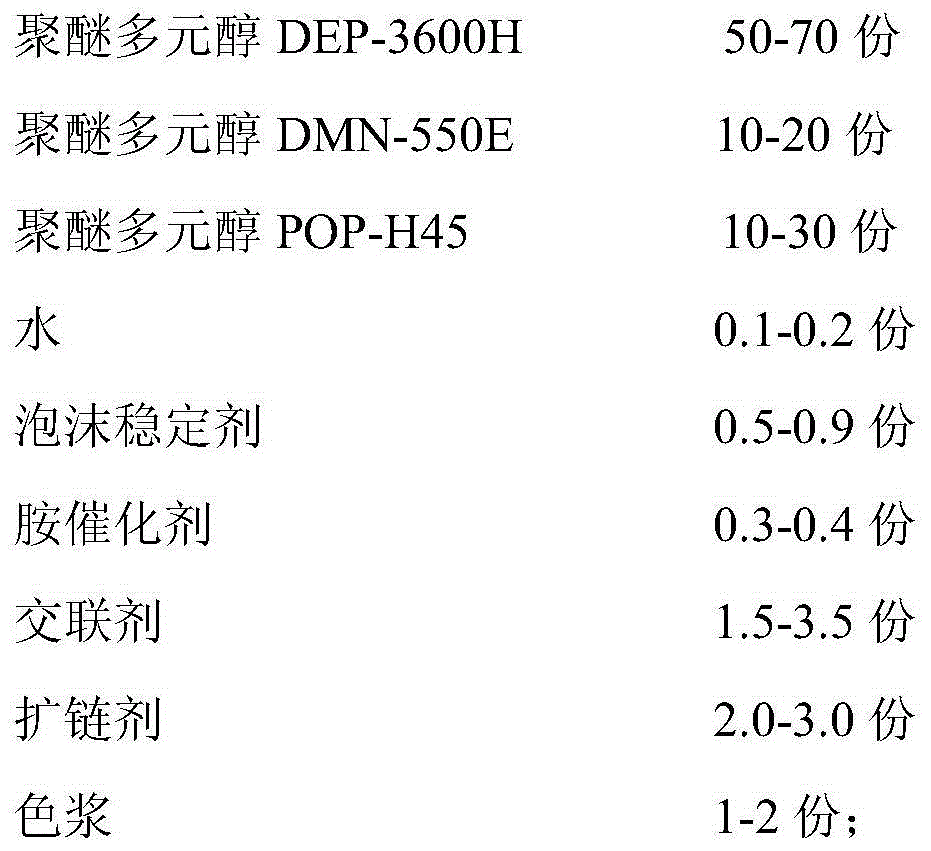

[0024] The composition of raw materials is as follows:

[0025] A component:

[0026]

[0027]

[0028] B component:

[0029] WANNATE 8019 45kg.

[0030] Put the raw materials of component A into the mixer and mix evenly, adjust the constant material temperature to 25°C, adjust the speed of the stirrer to 4200r / min, pour component B preheated to 25°C into component A and stir for 4.5s, and mix the mixture The material is poured into a mold preheated to 40°C, and the mold is demoulded after 6 minutes to obtain the product.

[0031] The product index is shown in Table 1.

[0032] Table 1 Example 1 product index

[0033]

Embodiment 2

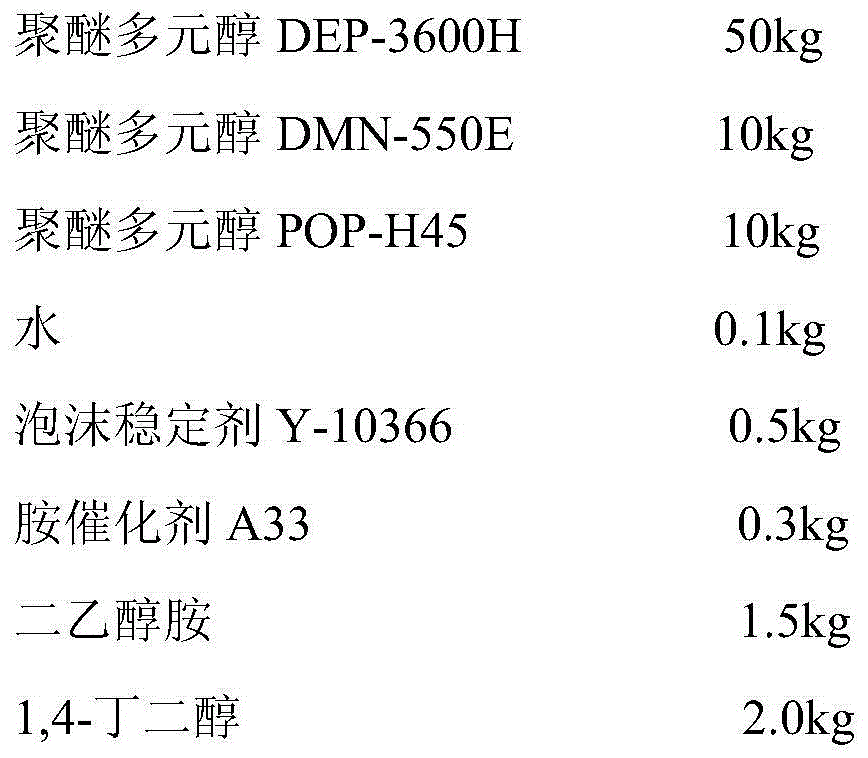

[0035] The composition of raw materials is as follows:

[0036] A component:

[0037]

[0038] B component:

[0039] WANNATE 8019 75kg.

[0040] Put the raw materials of component A into the mixer and mix evenly, adjust the constant material temperature to 23°C, adjust the speed of the agitator to 4000r / min, pour component B preheated to 23°C into component A and stir for 4s, and mix the material Pour it into a mold preheated to 35°C, and demould after 5 minutes to obtain the product.

[0041] Product indicators are shown in Table 2.

[0042] Table 2 embodiment 2 product index

[0043] Tensile strength (MP)

[0044]

Embodiment 3

[0046] The composition of raw materials is as follows:

[0047] A component:

[0048]

[0049] B component:

[0050] WANNATE 8019 60kg.

[0051] Put the raw materials of component A into the mixer and mix evenly, adjust the constant material temperature to 27°C, adjust the speed of the agitator to 4500r / min, pour the B component preheated to 27°C into the A component and stir for 5 seconds, and mix the material Pour it into a mold preheated to 45°C, and demould after 10 minutes to obtain the product.

[0052] Product indicators are shown in Table 3.

[0053] Table 3 embodiment 3 product index

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com