One-step preparation method for synthesizing polyimide-based micro/nano fibers

A polyimide and nanofiber technology, applied in the field of one-step synthesis of polyimide-based micro/nanofibers, can solve the problems of low yield, hinder development, and the preparation method has not yet been reported, and achieves high porosity, The effect of reducing energy consumption and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing polyimide-based micro / nano fibers by one-step synthesis, comprising the steps of:

[0028] (1) The monomer for preparing polyimide, pyrophthalic anhydride and initiator sodium methylate are dissolved in a four-necked flask equipped with N,N-dimethylacetamide, and diisocyanate is dissolved to a certain amount N,N-dimethylacetamide was added into a four-neck flask by quantitative dropwise, heated at 100° C., and reacted for 6 hours to prepare a polyimide polymer solution.

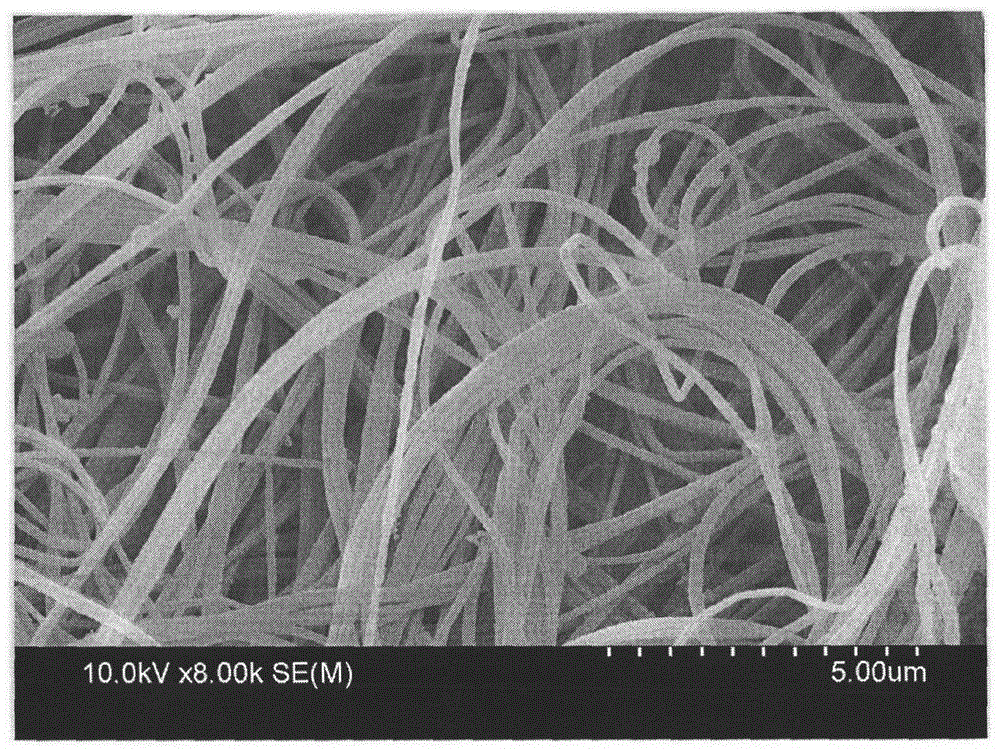

[0029] (2) Prepare the polyimide solution obtained in step (1) to the range of spinnable concentration, and prepare an optimized polyimide nanofiber mat by using solution jet spinning technology. In the solution jet spinning technology, the apparent viscosity of the solution is 3712mPa s, the airflow temperature is 80°C, the propulsion speed is 5ml / h, the diameter of the spinneret hole is 0.3mm, the airflow slit is 0.2mm, and the air flow rate of the air inlet is 700m 3 / h, the ...

Embodiment 2

[0033] A method for preparing polyimide-based micro / nano fibers by one-step synthesis, comprising the steps of:

[0034] (1) Prepare the monomer of polyimide, 3,3'-4,4'-biphenyl dianhydride and initiator sodium hydroxide solution in the four necks equipped with N,N-dimethylacetamide Dissolve in a flask, dissolve diisocyanate into a certain amount of N,N-dimethylacetamide, add it into a four-necked flask by quantitative dropwise, heat at 110°C, and react for 8 hours to prepare polyamide imine polymer solution.

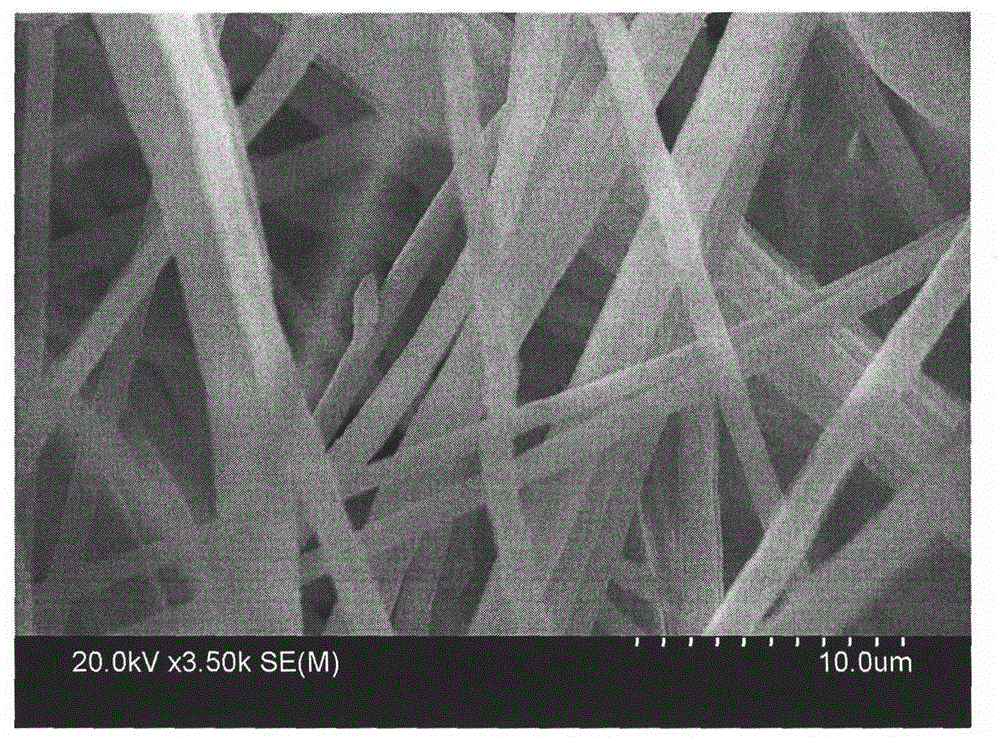

[0035] (2) Prepare the polyimide solution obtained in step (1) to the range of spinnable concentration, and prepare an optimized polyimide nanofiber mat by using solution jet spinning technology. In the solution jet spinning technology, the apparent viscosity of the solution is 4512mPa s, the airflow temperature is 90°C, the diameter of the spinneret hole is 0.5mm, the airflow slit is 0.3mm, and the gas flow rate of the air inlet is 900m 3 / h, the air flow at the exha...

Embodiment 3

[0039] A method for preparing polyimide-based micro / nano fibers by one-step synthesis, comprising the steps of:

[0040] (1) Dissolving the monomer for preparing polyimide, 3,3'-4,4'-benzophenonetetraacid dianhydride and initiator sodium methylate in a four-necked flask equipped with N-methylpyrrolidone , dissolving diisocyanate into a certain amount of N-methylpyrrolidone, adding it quantitatively to a four-neck flask, heating at 150°C, and reacting for 8 hours to prepare a polyimide polymer solution.

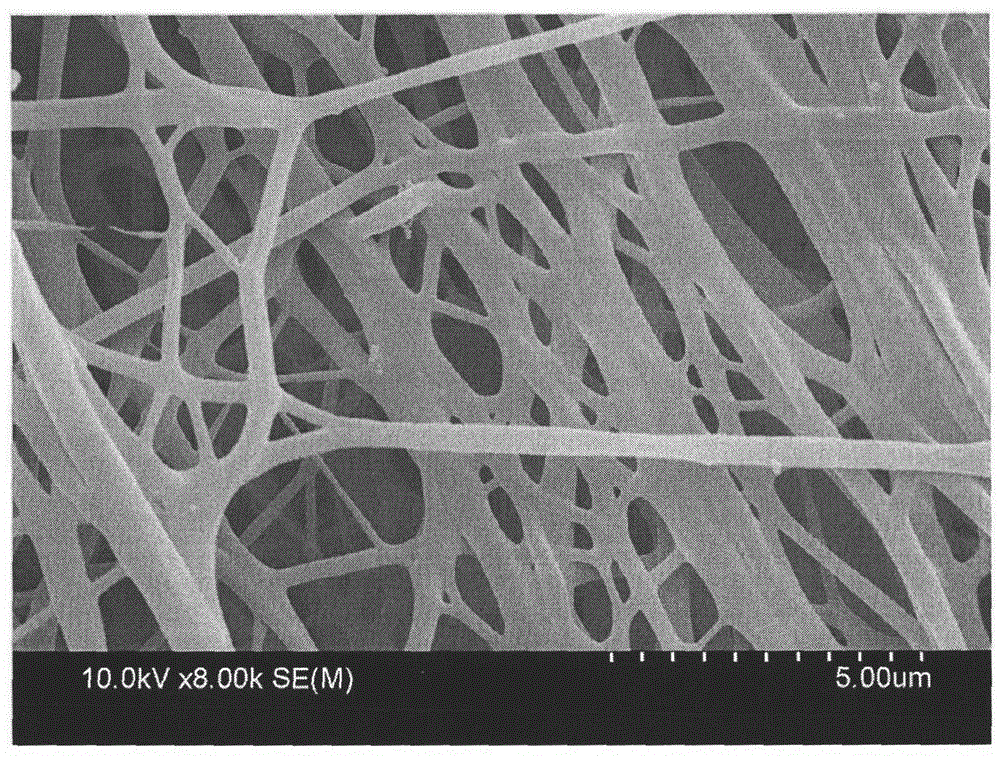

[0041] (2) Prepare the polyimide solution obtained in step (1) to the range of spinnable concentration, and prepare an optimized polyimide nanofiber mat by using solution jet spinning technology. In the solution jet spinning technology, the apparent viscosity of the solution is 7058mPa s, the airflow temperature is 90°C, the diameter of the spinneret hole is 0.75mm, the airflow slit is 0.5mm, and the air flow rate of the air inlet is 800m 3 / h, the air flow at the exhaust por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com