Novel energy-saving ball press machine

A briquette machine, a new type of technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problem that the two sets of parallel rollers of the briquette machine cannot run synchronously normally, and the sliding wear of the floating bearing seat and the upper and lower frames error, reduction of forming pressure of the briquette machine, etc., to achieve the effect of small pressure, stable operation of the pressing roller, and less steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

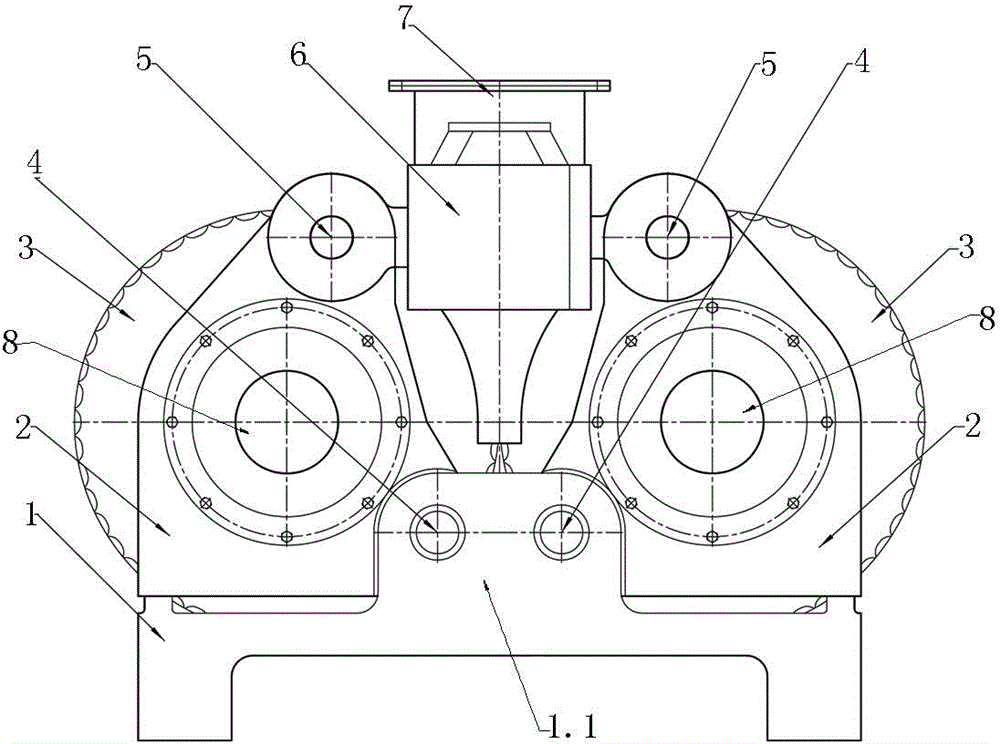

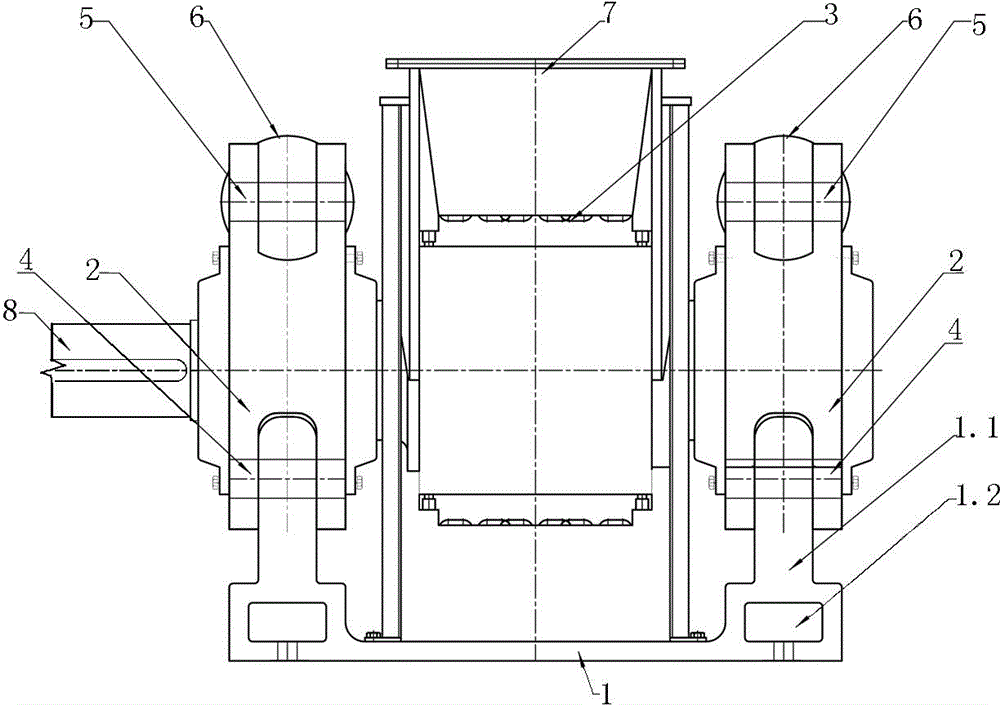

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0024] like figure 1 and figure 2 , the present invention relates to a new type of energy-saving briquetting machine, comprising a roller system, a feeding system, a transmission system and a hydraulic system, the feeding system is arranged above the roller system, including a feeding hopper 7 and a feeding control system, and the feeding hopper is erected on On the base 1 of the equipment, the roller system is connected to the transmission system to be driven by it. The transmission system includes a coupling, a reducer and a motor. The hydraulic system is connected to the roller system, including an oil cylinder and a hydraulic As for the pumping station, since the transmission system and the hydraulic system ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com