Segmental Grinding Method of Large Screw Compressor Rotor

A screw compressor and rotor technology, applied in the field of mechanical processing, can solve the problems of affecting the processing accuracy, increasing the load of the motor, increasing the size of the machine tool, etc., and achieve the effects of high processing accuracy, convenient modification and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

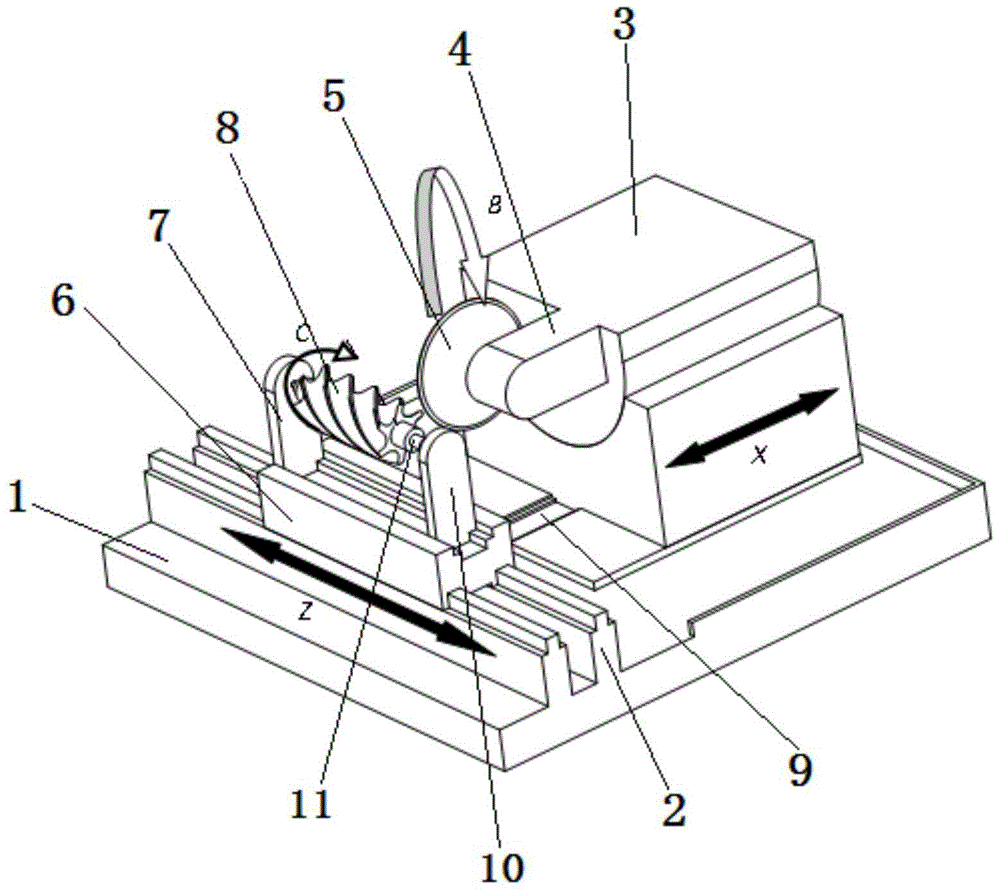

[0070] The subsection grinding device adopted in the present invention has a structure such as figure 1 As shown, including the bed 1, the bed 1 is respectively provided with a transverse guide rail 2 and a longitudinal chute 9, and the transverse guide rail 2 and the longitudinal chute 9 are perpendicular to each other; the longitudinal chute 9 is provided with a grinding wheel frame 3, and the grinding wheel frame 3 can Move along the longitudinal chute 9; one side of the grinding wheel frame 3 is provided with a boss 4, and one side of the boss 4 is provided with a grinding wheel 5; The workbench 6 is provided with a headstock 7 and a tailstock 10 parallel to each other, the headstock 7 is provided with a rotor clamping head for clamping the rotor workpiece 8, and the tailstock 10 is provided with a top for clamping the rotor workpiece 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com