A multifunctional drill clamp device

A multi-functional, drill-clamp technology, applied in the field of drilling processing machinery, can solve problems such as inconvenient measurement, moving parts position, drilling deviation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

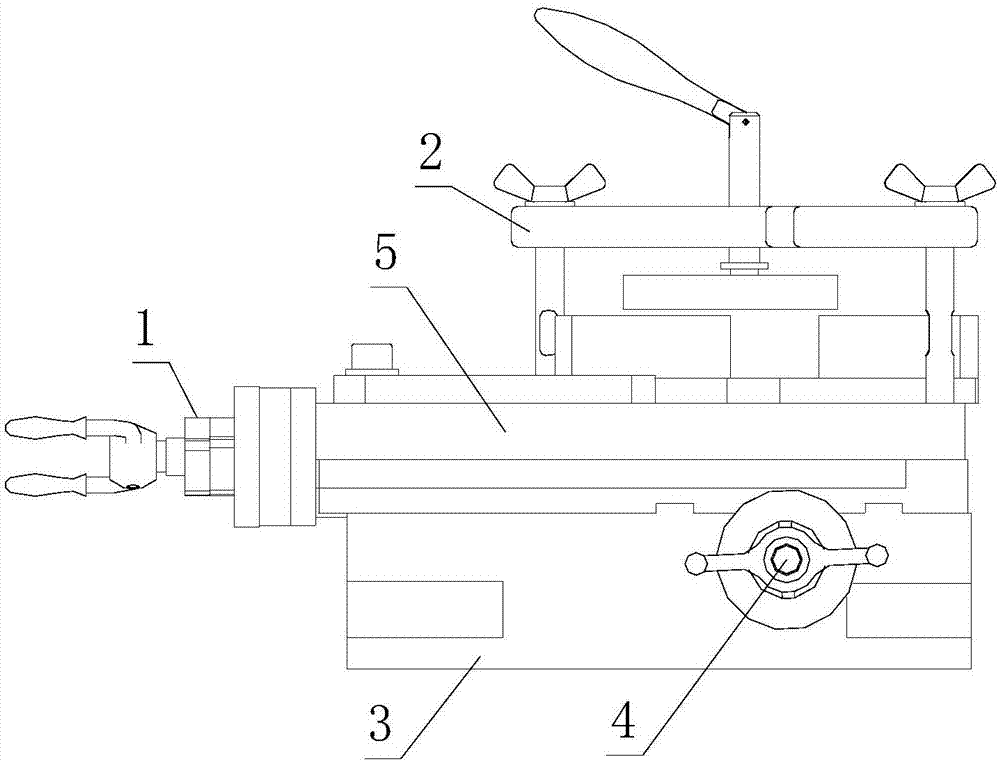

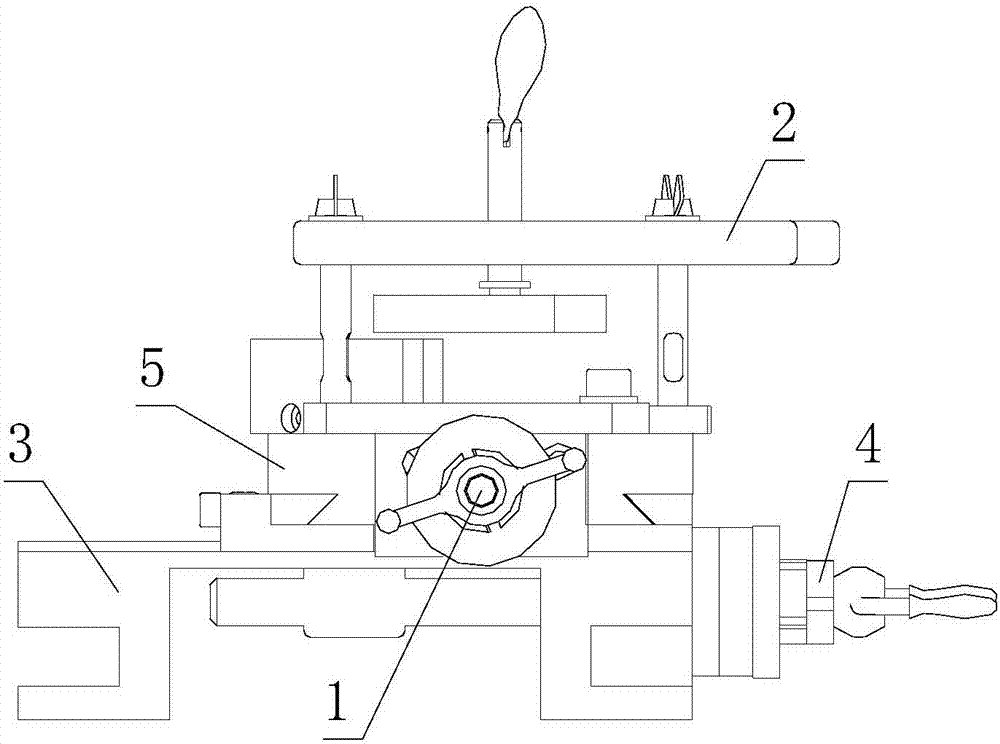

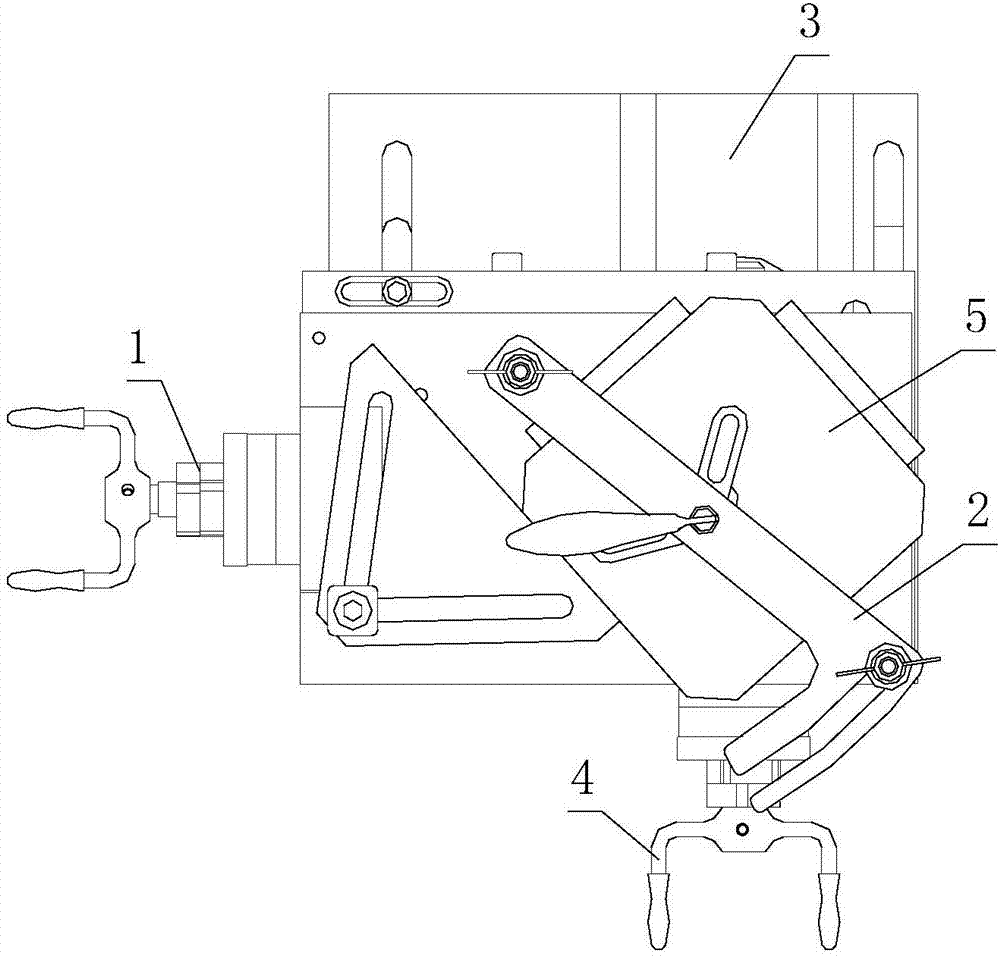

[0043] Such as Figure 1 to Figure 14 As shown, a kind of multifunctional drill chuck device according to the present invention includes a lateral movement operation mechanism 1, a pressing mechanism 2, a base 3, a longitudinal movement operation mechanism 4 and a vertical and horizontal movement mechanism 5, and the vertical and horizontal movement mechanism 5 It is composed of a lower supporting plate 51 and an upper supporting plate 53, wherein the lower supporting plate 51 and the upper supporting plate 53 are connected by a dovetail groove, the base 3 is provided with a slide rail 33, and the base 3 is connected with the set via the slide rail 33 Fitted and connected with the concave groove 511 at the bottom of the lower palle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com