Saline land improvement method

A technology of saline-alkali land and seeds, applied in the direction of soil preparation methods, fertilizer mixtures, agricultural machinery and implements, etc., can solve problems such as high engineering, maintenance and management costs, high investment in drainage projects, excessive water consumption, etc., to improve permeability ability and nutrient status, improve fertilizer retention, and reduce the effect of soil alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

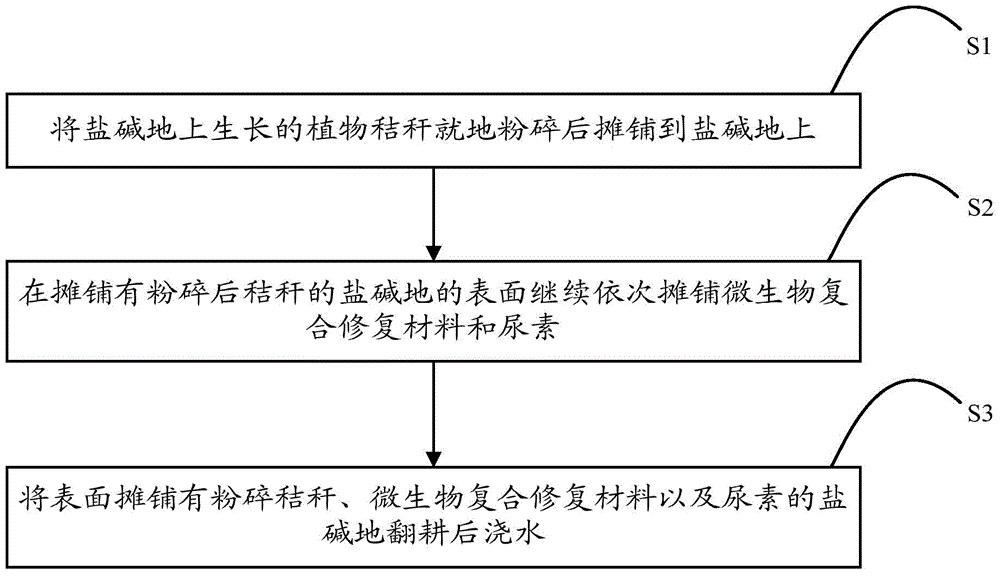

Method used

Image

Examples

Embodiment 1

[0065] Crush the plant stalks growing on the coastal saline-alkali land into pieces with a length of less than 10 cm, spread them as evenly as possible on the surface of the saline-alkali land, and then continue to spread microbial composite repair materials (150 kg / mu) on the surface of the saline-alkali land in sequence ) and urea (15 kg / mu); mechanical tillage, and the tillage depth is 20-30 cm. After the tillage is completed, the soil after the tillage will be watered thoroughly, and the restoration will be completed after 15-20 days.

[0066] The formula of microbial composite restoration material is: 4 parts of organic manure, 2 parts of humic acid, 0.7 part of agricultural organic waste, 0.2 part of marine organic waste, 0.01 part of liquid bacterial agent, and 0.005 part of solid microbial agent.

[0067] Among them, organic manure includes any proportion of cow manure, pig manure, sheep manure and chicken manure; agricultural organic waste includes any proportion of pe...

Embodiment 2

[0069] Crush the plant stalks growing on the coastal saline-alkali land into pieces with a length of less than 10 cm, spread them as evenly as possible on the surface of the saline-alkali land, and then continue to spread microbial composite restoration materials (200 kg / mu) on the surface of the saline-alkali land ) and urea (15 kg / mu); mechanical tillage, and the tillage depth is 20-35 cm. After the tillage is completed, the soil after the tillage will be watered thoroughly, and the restoration will be completed after 15-20 days.

[0070] The formula of the microbial composite restoration material is: 6 parts of organic manure, 4 parts of humic acid, 3 parts of agricultural organic waste, 0.4 part of marine organic waste, 0.02 part of liquid bacterial agent, and 0.01 part of solid microbial agent.

[0071] Among them, organic manure includes any proportion of cow manure, pig manure, sheep manure and chicken manure; agricultural organic waste includes any proportion of peat, r...

Embodiment 3

[0073] Crush the plant stalks growing on the coastal saline-alkali land into pieces with a length of less than 10 cm, spread them as evenly as possible on the surface of the saline-alkali land, and then continue to spread microbial composite restoration materials (300 kg / mu) on the surface of the saline-alkali land ) and urea (20 kg / mu); mechanical tillage, and the tillage depth is 20-35 cm. After the tillage is completed, the soil after the tillage will be watered thoroughly, and the restoration will be completed after 15-20 days.

[0074] The formula of the microbial composite restoration material is: 4 parts of organic manure, 3 parts of humic acid, 1.4 parts of agricultural organic waste, 0.3 part of marine organic waste, 0.014 part of liquid bacterial agent, and 0.007 part of solid microbial agent.

[0075] Among them, organic manure is cow dung and chicken manure (the weight ratio is 4:1.3); agricultural organic waste includes any proportion of straw, rice husk powder, mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com