Handpiece having direct cooling type slimmed driving part

A technology of driving parts and handpieces, applied in fixed tubular catheter components, surgery, manufacturing tools, etc., can solve problems such as injection of salt water, reduction of heat cooling effect, vibration and noise, etc., to prevent engine overheating, realize miniaturization, Realize the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, specific contents for implementing the present invention will be described in more detail with reference to the accompanying drawings.

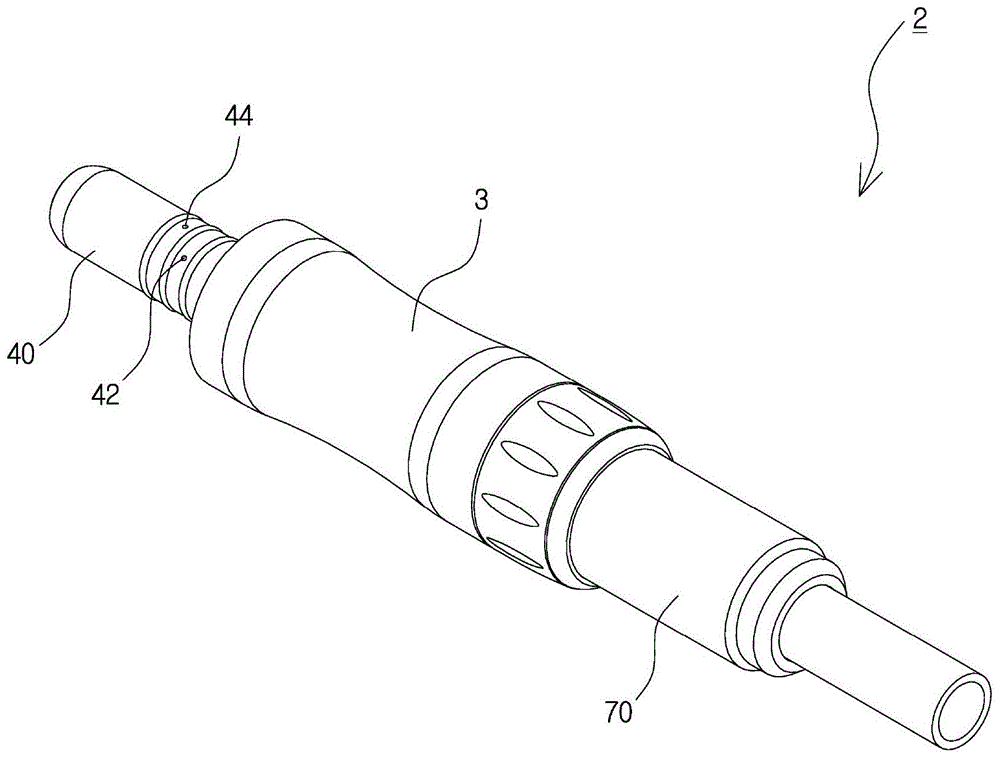

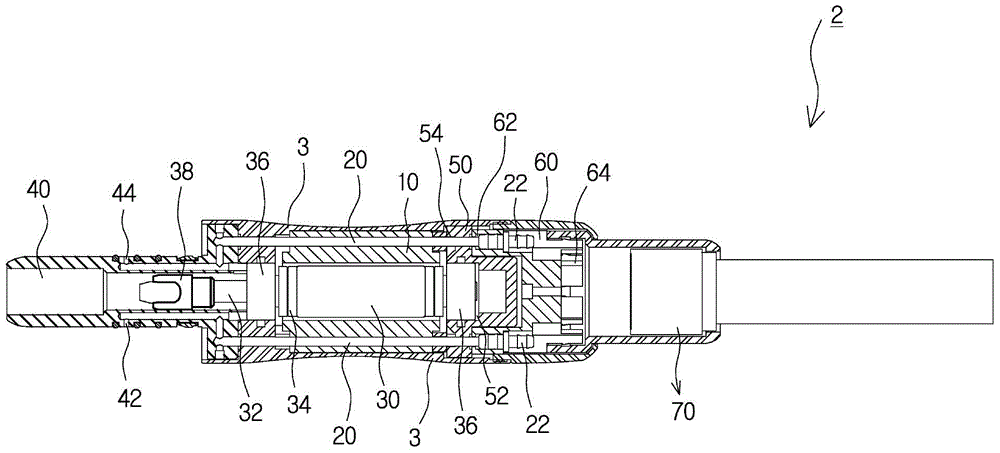

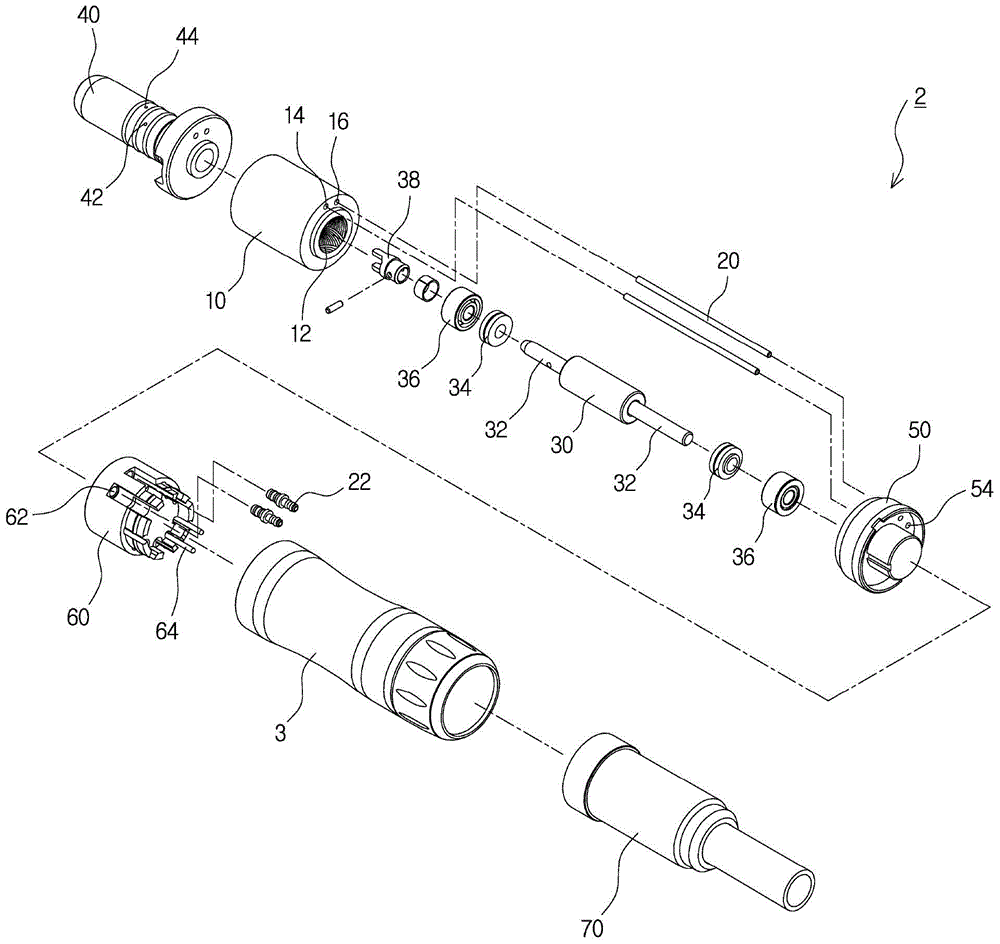

[0021] refer to Figure 1 to Figure 4 , according to the handpiece with direct cooling light-duty driving part of the present invention, it includes an outer shell (3) that is shaped like a stick and can be held by hand, is inserted into the inner side of the outer shell (3), and is formed with a ventilation hole ( 14) and the cylindrical magnetic core (10) of water injection hole (16), the pipeline (20) that is respectively inserted in the ventilation hole (14) of described magnetic core (10) and water injection hole (16) and forms, by A rotor (30) formed of a cylindrical magnet inserted inside the magnetic core (10), and a cylindrical support on both sides of a transmission shaft (32) coupled to the rotor (30) are respectively sandwiched. ring (34), a pair of bearings (36) arranged in front and rear of the support ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com