New method for leakage detection of Freon valve

A freon and new method technology, applied in the field of valve supervision and inspection, can solve the problems of insufficient precision, short time consumption, high detection cost, etc., and achieve the effects of ensuring detection accuracy, increasing pressure and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

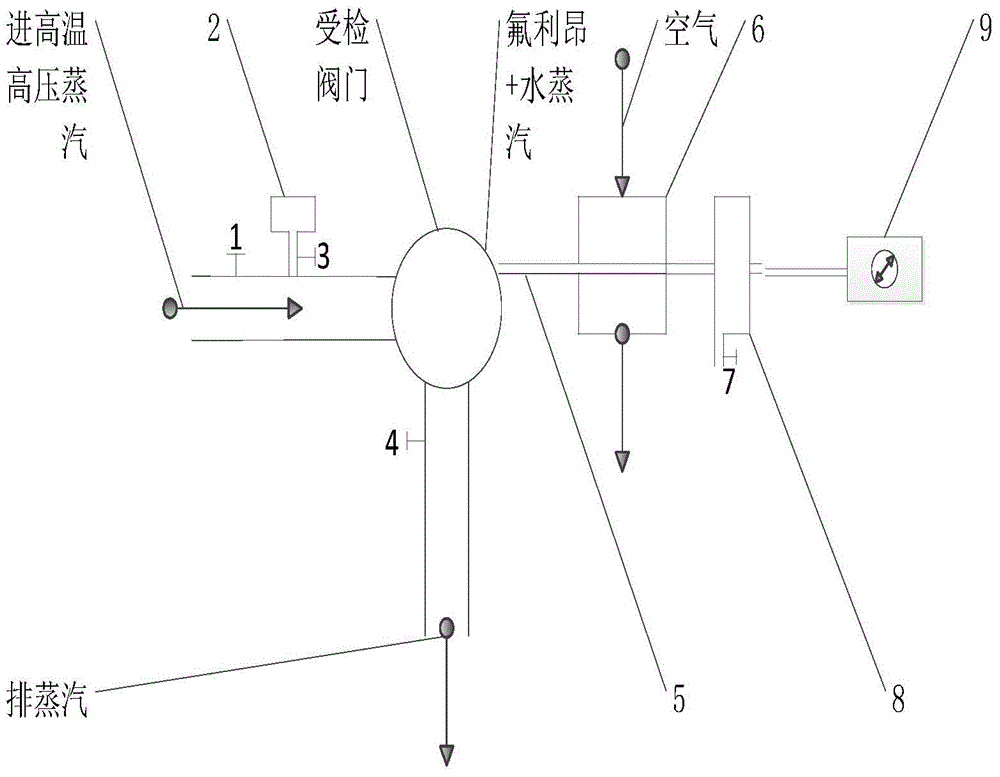

[0010] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0011] The working process of the present invention is as follows: arrange according to the schematic diagram of the device, align the probe of the halogen detector 9 with the outlet of the gas-liquid separation device 8, and because the gas density of Freon is higher than that of air, the probe of the halogen detector 9 should be close to the gas-liquid separation device 8 The lower edge of the gas outlet, the horizontal distance between the probe of the halogen detector 9 and the gas outlet of the gas-liquid separation device 8 is not more than 3mm. Open the high-temperature and high-pressure steam control valve 1, the exhaust steam valve 4 and the inspected valve, and close the Freon control valve 3 at the same time, and pass the high-temperature and high-pressure steam into the high-temperature and high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com