Heating furnace

A heating furnace and furnace body technology, applied in the field of heating furnaces, can solve problems such as poor sealing of furnace doors and damage to furnace bricks, and achieve the effects of good sealing, improving thermal efficiency and prolonging heat transfer time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

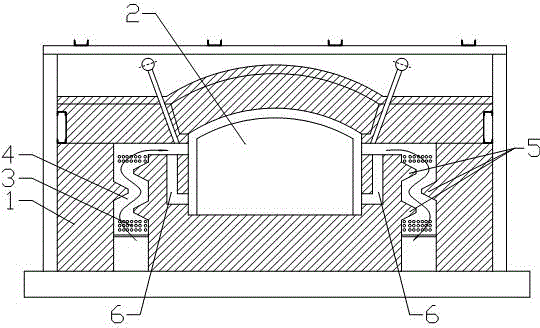

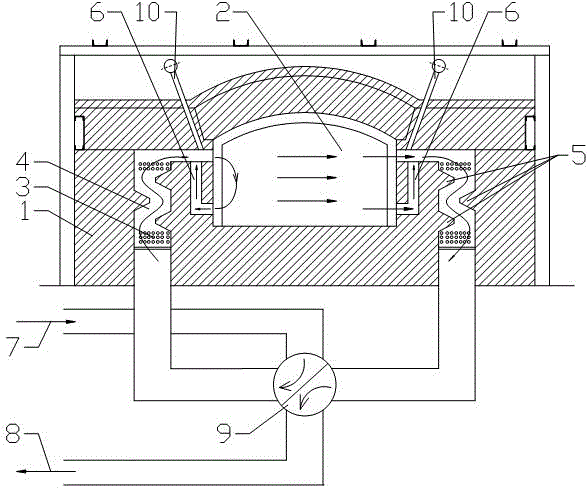

[0055] see figure 1 , the present invention relates to a regenerative heating furnace with a circulation channel, comprising a furnace body 1, a furnace chamber 2, a furnace door and a furnace door sealing structure, a pair of regenerator chambers 4 and a pair of circulation chambers are arranged in the furnace body 1 Channel 6, the circulation channel 6 is on the inside, the regenerator 4 is on the outside, one end of the circulation channel 6 communicates with the regenerator 4, and the other end communicates with the lower part of the furnace 2, and the inner wall of the regenerator 4 is arranged with a separation layer from top to bottom 5. The heat storage chamber 4 is filled with heat storage balls 3 .

[0056] Working principle of heating furnace:

[0057] Working condition one: see figure 2 , the reversing valve 9 turns to the position shown in the figure, and the air 7 enters figure 2 The heat storage chamber 4 on the left side of the center exchanges heat with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com