Multistage liquefaction apparatus driven by loop thermoacoustic engine

A technology of thermoacoustic engine and liquefaction device, applied in liquefaction, refrigeration and liquefaction, gas cycle refrigerator, etc., can solve the problems of increasing system complexity and restricting applications, achieve good application prospects, reduce production costs, reduce transmission The effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

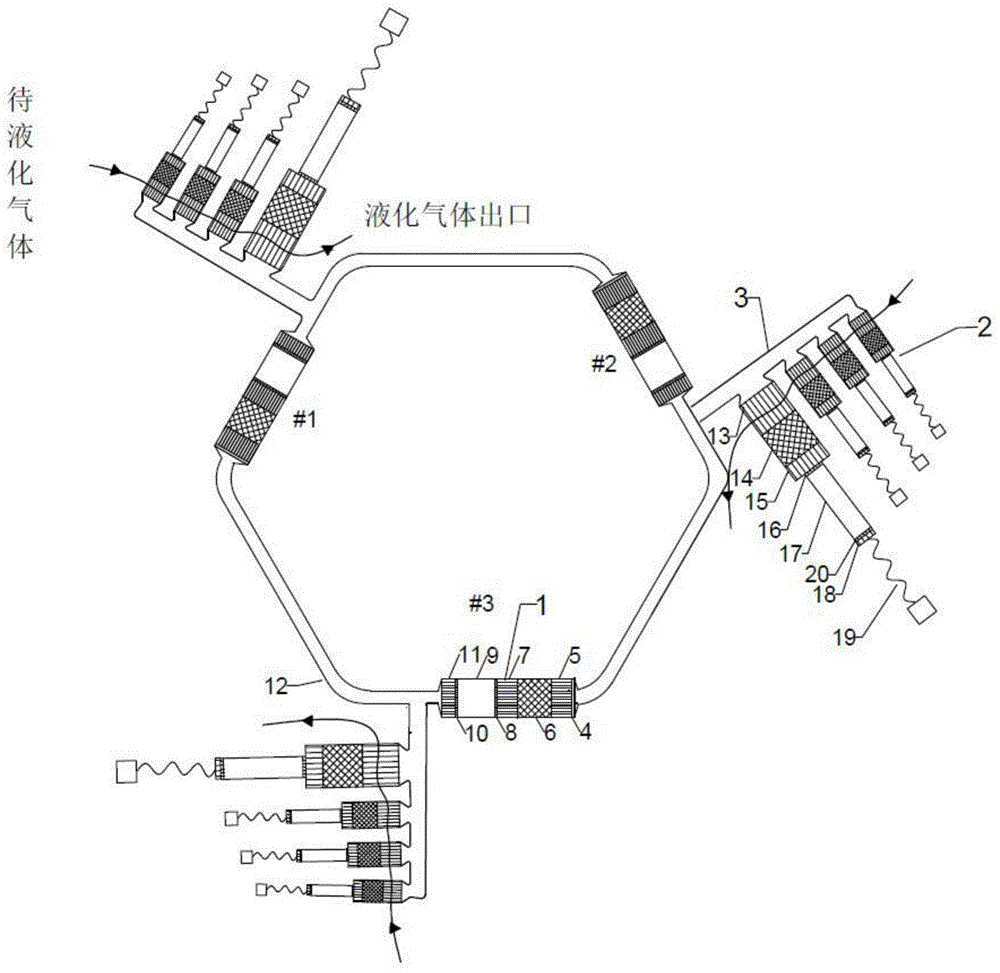

[0027] figure 2 It is a structural schematic diagram of a gas multistage liquefaction device (embodiment 1) driven by a loop multistage thermoacoustic engine of the present invention; as figure 2 As shown, the gas multi-stage liquefaction device in this embodiment 1 consists of 3 (#1 thermoacoustic engine unit, #2 thermoacoustic engine unit and #3 thermoacoustic engine unit) identical thermoacoustic engine units and 3 bypass 3 components; 3 thermoacoustic engine units are connected end to end through a resonance tube 12 to form a loop structure; each bypass 3 is connected to 4 pulse tube refrigerator units 2, and the size is from the far end far away from the resonance tube 12 to the proximal end From small to large; each bypass is at the junction of the outlet of the engine sub-cooler 11 and the resonant tube 12;

[0028] Each stage of thermoacoustic engine unit 1 is composed of DC suppressor 4, engine main cooler 5, engine regenerator 6, heater 7, high temperature end lam...

Embodiment 2

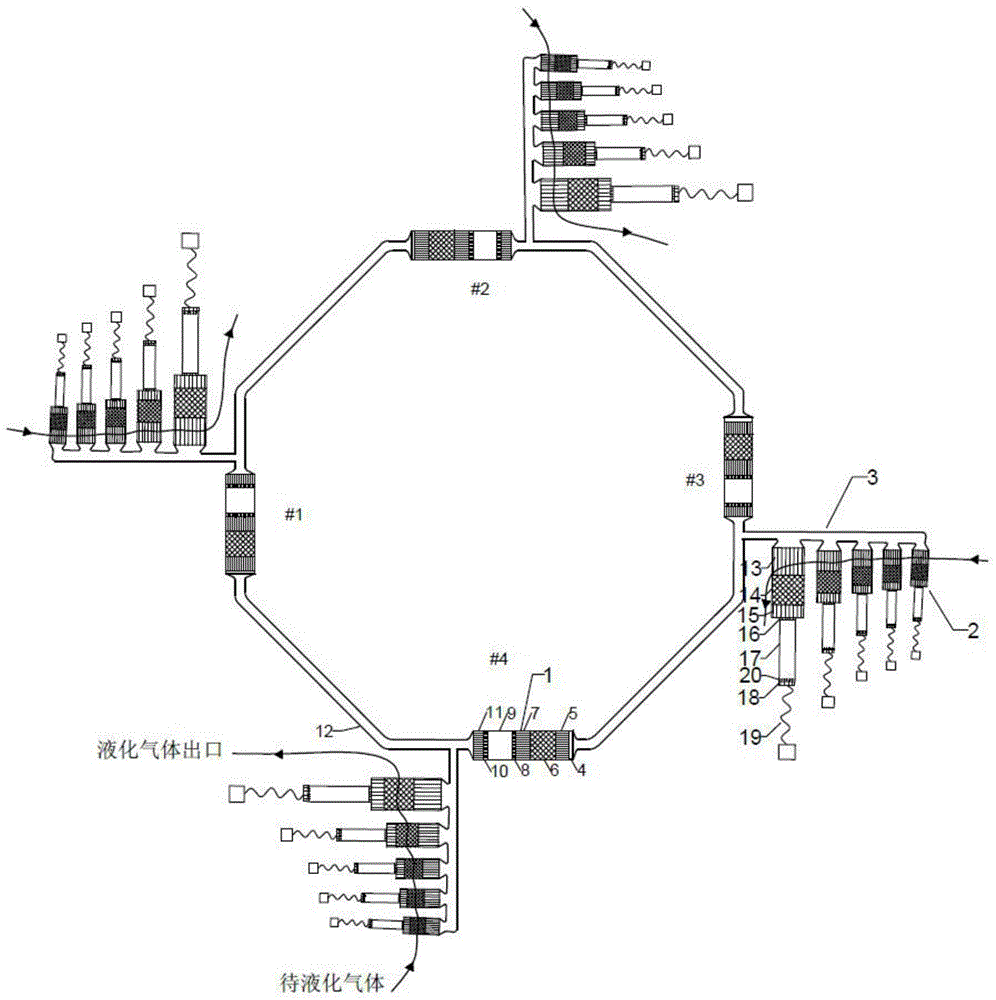

[0033] image 3 It is a structural schematic diagram of a gas multistage liquefaction device (embodiment 2) driven by a loop multistage thermoacoustic engine of the present invention; as image 3 As shown, the gas multistage liquefaction device of the present embodiment 2 consists of 4 (#1 thermoacoustic engine unit, #2 thermoacoustic engine unit, #3 thermoacoustic engine unit and #4 thermoacoustic engine unit) identical (length and Cross-sectional area) thermoacoustic engine unit and four bypasses 3; the thermoacoustic engine units at all levels are connected end-to-end through resonant tubes 12 of the same size to form a loop structure; each bypass 3 is connected to 5 size by Small to large pulse tube refrigerator units 2; each stage of bypass is at the connection between the outlet of each engine subcooler 11 and the resonant tube 12;

[0034] Each stage of thermoacoustic engine unit 1 is composed of DC suppressor 4, engine main cooler 5, engine regenerator 6, heater 7, hi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap