Floor tile cement sand flattening machine

A technology for leveling machines and floor tiles, which is applied in construction, building construction, etc., and can solve problems such as hollowing, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

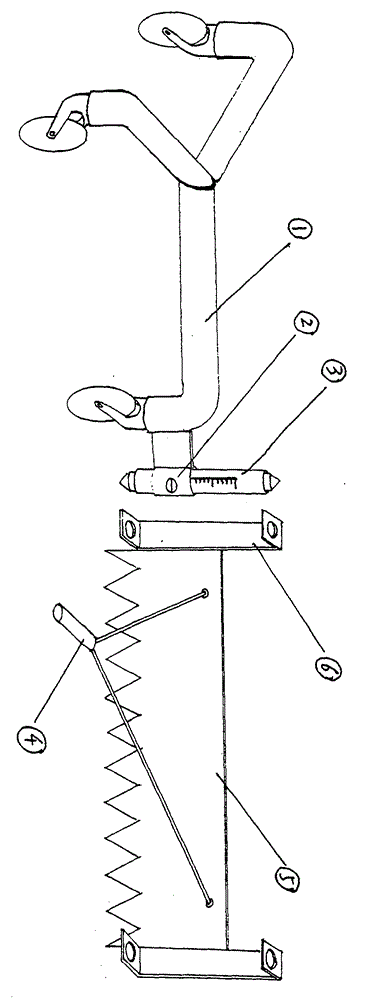

[0006] Connect the trolley ① and the scraper ⑤ through the vertical rod ③ (see the attached picture of the abstract), adjust the scale on the vertical rod relative to the casing according to the thickness of the lime sand to be spread, that is, determine the height of the scraped lime sand surface. Tighten the screws and place the trolley on the laid floor tiles, and place the scraper on the lime sand surface to be laid. Pull the handle ④, then the universal wheel at the pole moves linearly on the floor tiles, and at the same time, the trolley itself automatically and slowly rotates. Since the vertical rod always moves in parallel, the lime sand surface scraped by the scraper must be a plane parallel to the smooth surface, and it can be pressed on the floor tiles and shaken.

[0007] The principle of the invention is simple, the structure is simple, and the operation is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com