Extra-thick tempering EH40 steel for ocean engineering and preparation method thereof

A marine engineering, quenching and tempering technology, applied in the field of iron and steel metallurgy, can solve the problems of poor uniformity of extra-thick plates, achieve the effects of improving corrosion resistance, easy mass production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

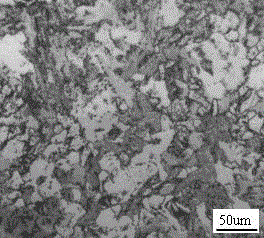

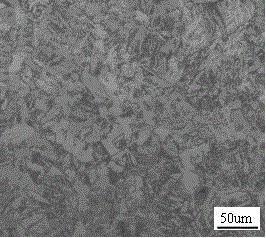

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0041] The chemical composition of the extra-thick quenched and tempered marine engineering EH40 steel corresponding to each embodiment of the present invention is shown in Table 1. The data in the table is the mass percentage content of each element, and the remainder is Fe and unavoidable impurity elements. Wherein embodiment 1, 2 corresponds to furnace number S11408150, and embodiments 3 and 4 correspond to furnace number S11408151.

[0042] Table 1

[0043]

[0044] Steel plate smelting process:

[0045] Smelting and continuous casting process: prepare materials according to the cost of the embodiment, pre-treat molten iron with KR, and deeply desulfurize, so that the sulfur content is lower than 0.0020%, and the slag is cleaned. % (carbon is added twice successively), blowing argon for 15 to 20 minutes during the tapping process, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com