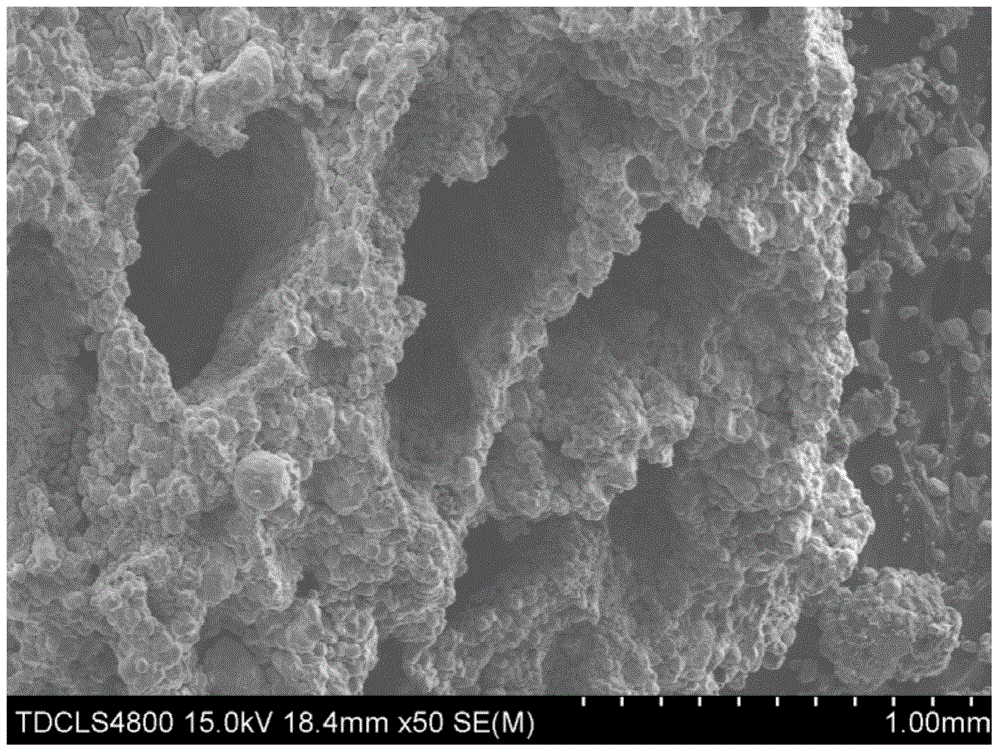

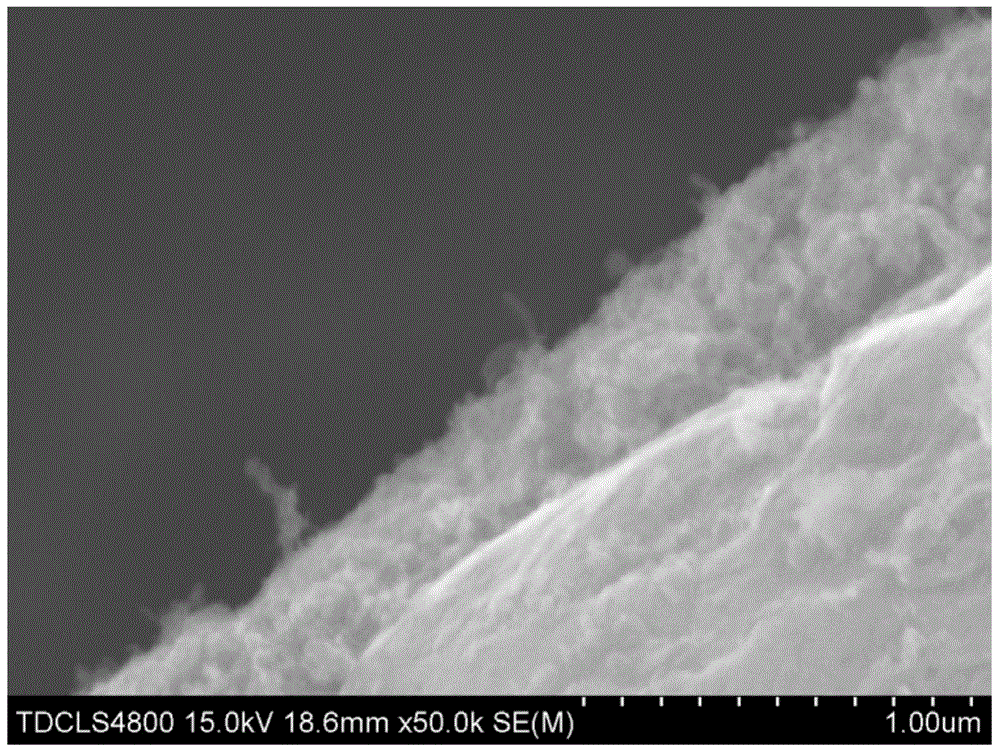

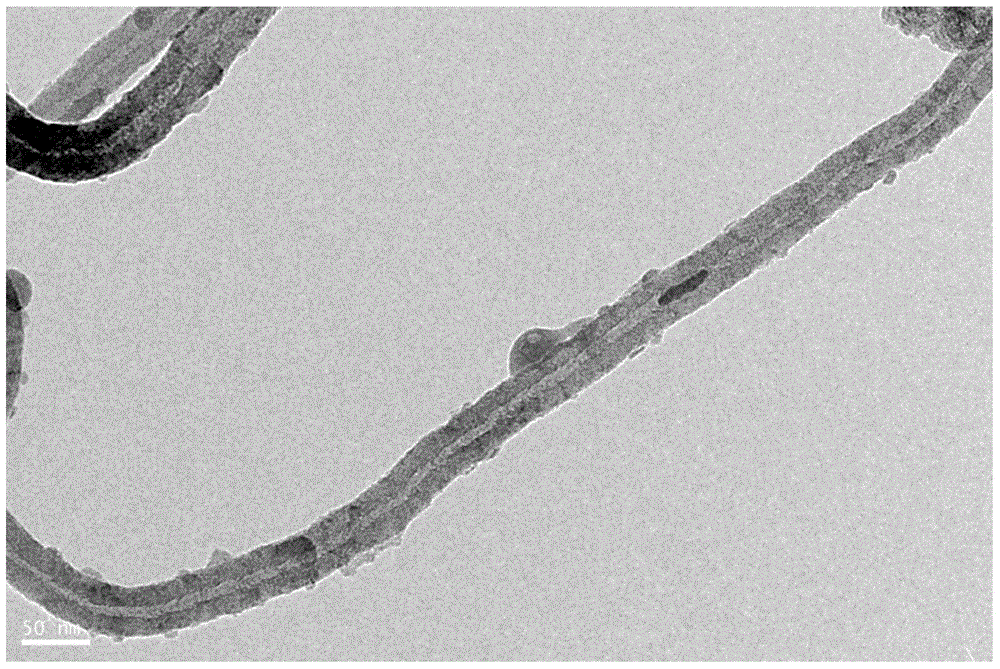

Preparation method of carbon nanotube reinforced foamed aluminum composite material for vibration attenuation and energy absorption

An aluminum composite material, carbon nanotube technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problem of difficult to achieve functional structure integration of foamed aluminum, low mechanical properties and buffer energy absorption performance, Complex preparation process and other problems, to achieve the effect of large stress, excellent mechanical properties, and improved energy absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first step, the preparation of the mixed powder of nickel nitrate, urea and aluminum powder:

[0033] First, put the spherical urea particles with a particle size of 0.45mm in an electric heating constant temperature drying oven, and dry them at 60°C for 1 hour. Put the nickel nitrate particles in an electric heating constant temperature drying oven, and dry them at 35°C for 1 hour. Ball mill 30min with the rotating speed of 200rpm / min on the planetary ball mill, be nickel nitrate according to mass ratio: the ratio of aluminum powder=0.001, take the atomized aluminum powder that the nickel nitrate after ball milling and particle diameter are 40 μ m, put the two Put into the ball mill jar, carry out ball milling 30min with the rotating speed of 200rpm / min on the ball mill, obtain the powder that nickel nitrate and aluminum powder evenly mix, according to volume ratio be aluminum powder: the ratio of urea=0.11:1 takes by weighing the dried urea granules , mixed with t...

Embodiment 2

[0043] The first step, the preparation of the mixed powder of nickel nitrate, urea and aluminum powder:

[0044] First, put spherical urea particles with a particle size of 1.2mm in an electric heating constant temperature drying oven, and dry them at 70°C for 1.5h. Put the nickel nitrate particles in an electric heating constant temperature drying oven, and dry them at 40°C for 1.5h. Nickel particle is ball milled 45min with the rotating speed ball mill of 200rpm / min on the planetary ball mill, is nickel nitrate according to mass ratio: the ratio of aluminum powder=0.01, takes by weighing the nickel nitrate after ball milling and particle diameter and is the atomized aluminum powder of 50 μ m, and two put into the ball mill tank, carry out ball mill 45min with the rotating speed of 200rpm / min on the ball mill, obtain the powder that nickel nitrate and aluminum powder evenly mix, be aluminum powder according to volume ratio: the ratio of urea=2:1 takes by weighing after drying ...

Embodiment 3

[0051] The first step, the preparation of the mixed powder of nickel nitrate, urea and aluminum powder:

[0052] First, put the spherical urea particles with a particle size of 2mm in an electric heating constant temperature drying oven, and dry them at 80°C for 2h. Put the nickel nitrate particles in an electric heating constant temperature drying oven, and dry them at 45°C for 2h. Ball mill 60min with the rotating speed of 200rpm / min on the planetary ball mill, be nickel nitrate according to mass ratio: the ratio of aluminum powder=0.02, take by weighing the nickel nitrate after ball milling and the atomized aluminum powder that particle diameter is 60 μm, put the two into In the ball mill jar, carry out ball milling 60min with the rotating speed of 200rpm / min on the ball mill, obtain the powder that nickel nitrate and aluminum powder evenly mix, be aluminum powder according to volume ratio: the ratio of urea=4:1 takes by weighing the dried urea granule, Mixing with the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com