Technique for removing polycyclic aromatic hydrocarbon components in heavy oil product

A technology for condensed aromatic hydrocarbons and heavy substances, which is applied in the technical field of removing condensed aromatic hydrocarbon components in heavy oil products, can solve the problems of low yield of final products, low content of condensed aromatic hydrocarbons, etc., and achieves good hydrogenation effect. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

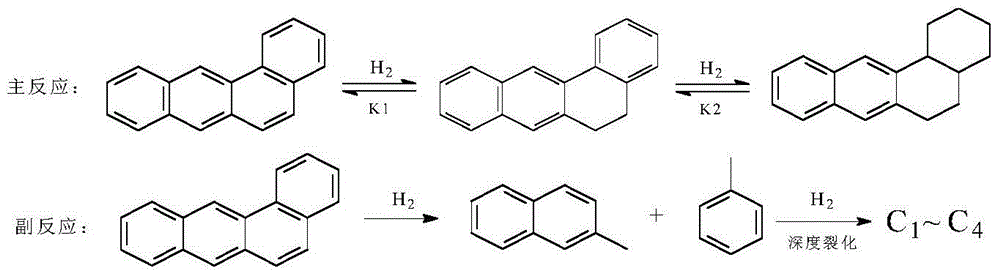

Method used

Image

Examples

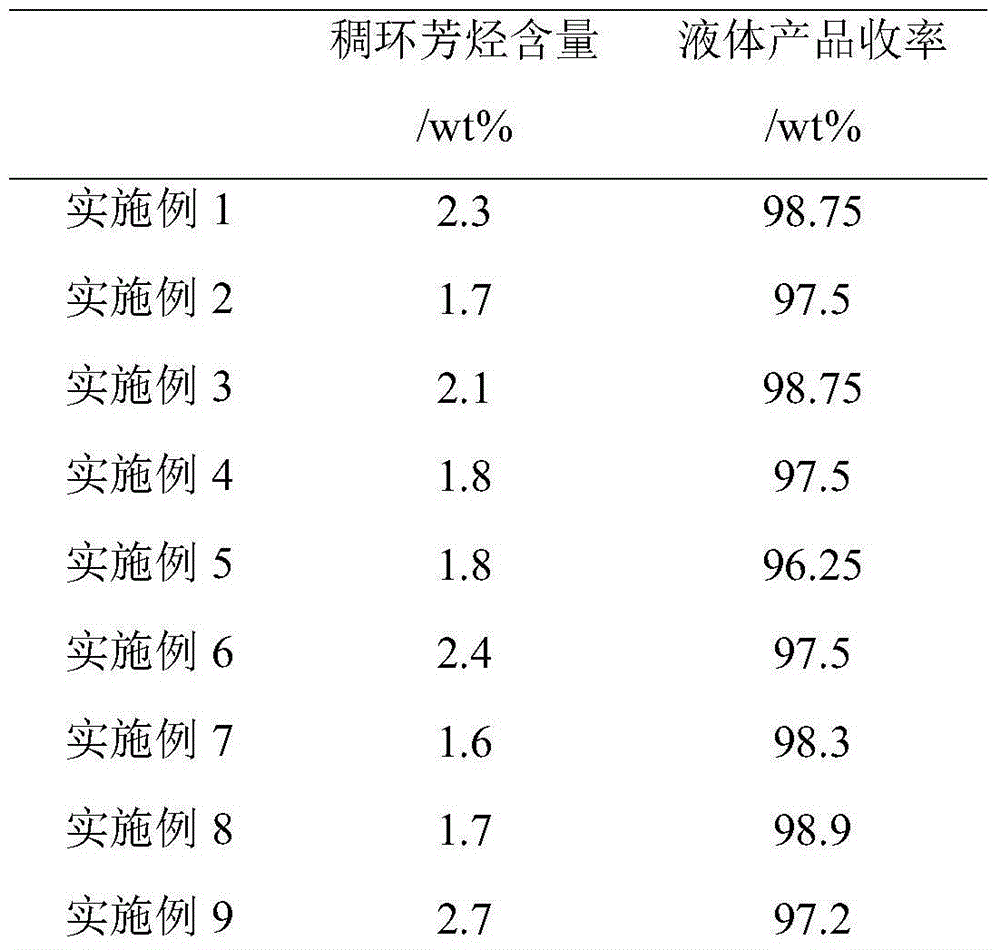

Embodiment 1

[0019] Add 80g of heavy oil and 24g of Pd-Pt / Yb / USY molecular sieve catalyst into a 500mL reaction kettle equipped with a stirrer, electric heater, thermocouple and pressure controller, discharge the air inside with nitrogen, and set the stirring in the kettle The rate is 300r / min, the reaction temperature is 300°C, feed fresh hydrogen to 10.0MPa, after 4 hours of reaction, pass cooling water until the temperature in the kettle drops to 80°C, discharge the residual gas, open the kettle to take out the material, filter out the catalyst particles, 79 g of liquid product was obtained and tested for fused-ring aromatics content.

Embodiment 2

[0021] The steps are the same as in Example 1, except that the reaction time is 6 hours to obtain 78g of the final liquid product.

Embodiment 3

[0023] The steps are the same as in Example 1, except that the reaction temperature is 340° C. to obtain 79 g of the final liquid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com