Material perfusion and filling device and process for narrow and long space

A filling device and a long and narrow technology are applied in the field of production process equipment for filling filling, which can solve the problems of restricting the promotion and application of new materials, poor uniformity of filling materials, and difficulty in controlling waste and cost, so as to achieve ingenious and reasonable process design, ensure quality and Consistency, the effect of solving production problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

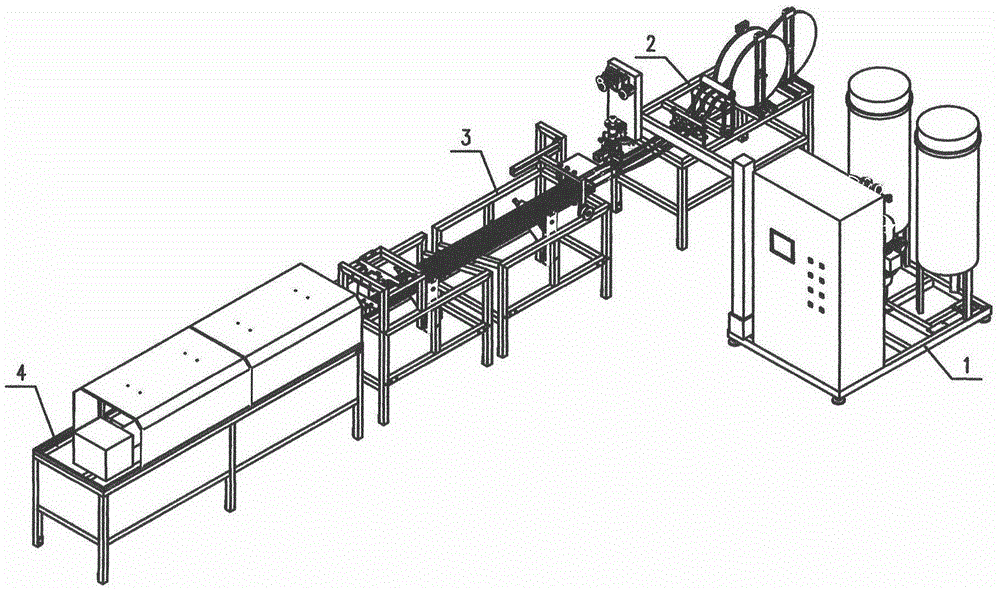

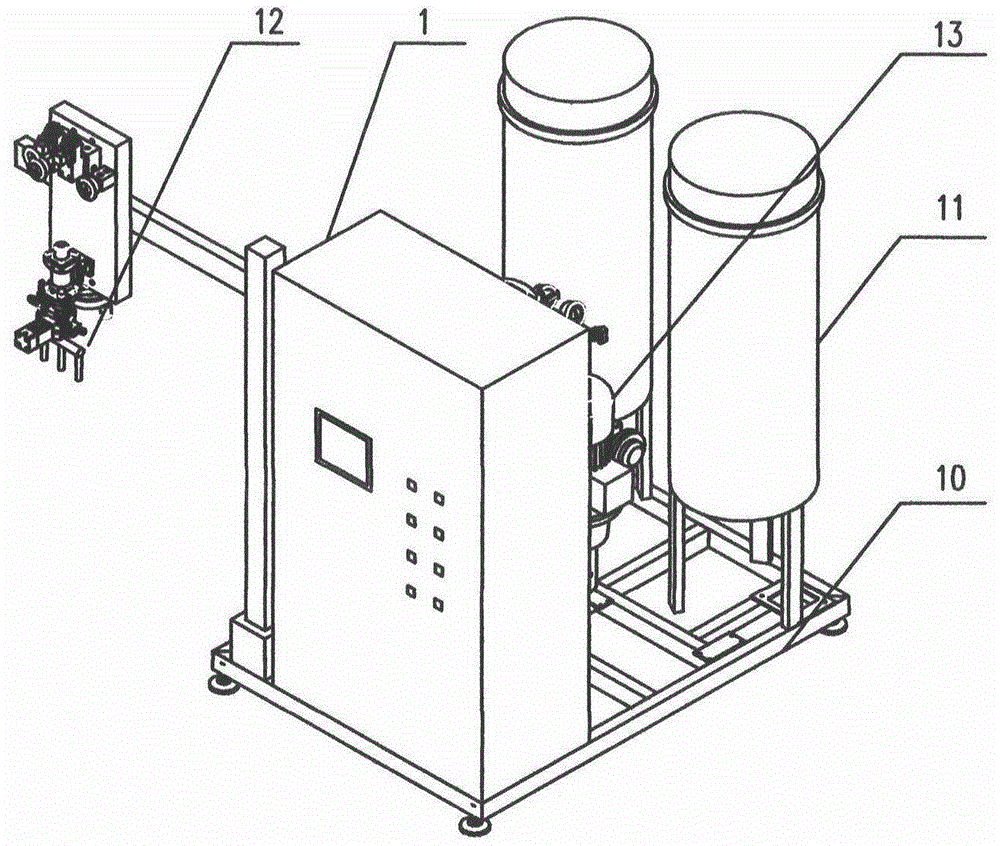

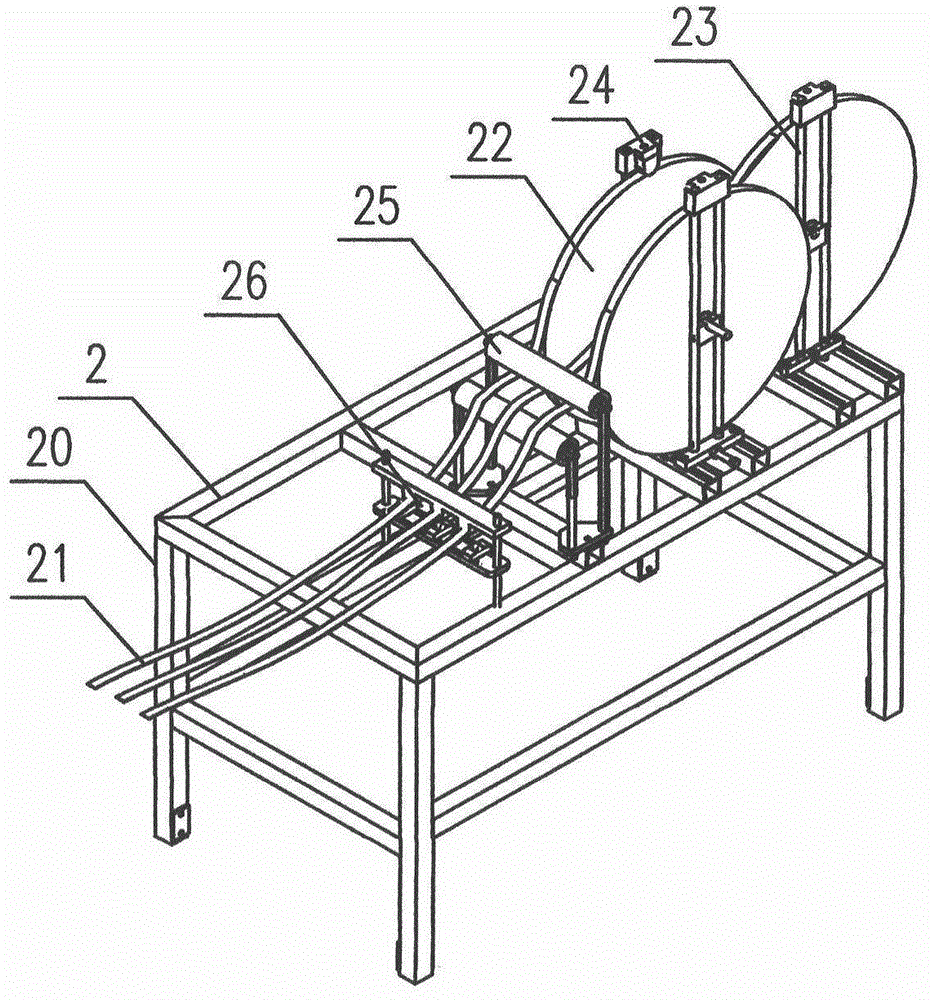

[0037] Embodiment 1: Referring to the accompanying drawings, a material pouring and filling device for a narrow and long space includes: a pouring host 1, a carrier folding conveying part 2, a filling profile positioning part 3 and a carrier pulling part 4; the carrier folding conveying part is arranged on The left end of the perfusion filling device, the profile positioning part is set at the middle position of the perfusion filling device, the carrier traction part is set at the right end of the perfusion filling device; the perfusion host is set at the carrier folded conveying part and the outside of the joint of the profile positioning part; the perfusion host includes: a base 10, a material storage container 11, a discharge port 12 and a delivery pump 13; the material storage container, the discharge port and the delivery pump are fixedly arranged on On the base, the conveying pump is respectively connected to the discharge port and the material storage container through t...

Embodiment 2

[0046] Embodiment 2: A material perfusion filling device for narrow and long spaces and a perfusion filling process, the following steps are adopted:

[0047] Step 1: Adjust the traction speed of the carrier traction part of the device according to the filling requirements. The following requirements must be met: the filling material pumped by the filling machine to the carrier will completely enter the filling cavity of the filling workpiece with the carrier, and the foaming and swelling will be completed in time. . The traction speed of the adjusted present embodiment is 10cm / second; then the starting device is in a standby state;

[0048] Step 2: Place the filling profile, that is, the workpiece with a narrow and long filling cavity. In this embodiment, it is a steel pipe with a length of one or two meters and an inner cavity diameter of 5 cm. Place it on the profile positioning frame for positioning and fixing, and press the confirmation button to notify the device to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com