Method for restoring and reutilizing LED (Light Emitting Diode) discarded substrate

A technology for substrates and epitaxial wafers, which is applied in the field of recovery and reuse of LED scrap substrates, can solve problems such as long process time, high operating temperature, and potential safety hazards, and achieve the effects of short process time, safety, operation, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for recovering and reusing LED scrap substrates, comprising the following steps:

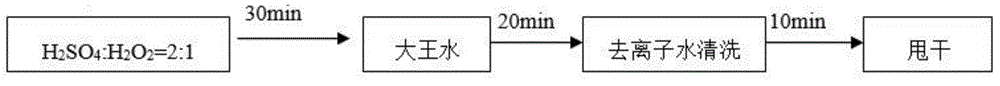

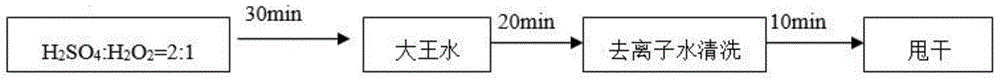

[0023] (1) First use the epitaxial waste film to use H 2 SO 4 :H 2 o 2 = 2:1 and other chemical liquid cleaning, clean the scrapped epitaxial wafers and rinse with water to dry them.

[0024] (2) Fast engraving process Cl 2 / BCl 3 The / Ar ratio is about 10:2:1, the upper electrode power is 1000w, the lower electrode power is about 300w, and the etching depth is 5um.

[0025] (3) The lithography process removes GaN and at the same time removes the unevenness caused by fast etching, which effectively improves the appearance of PSS after regeneration. This process uses the upper electrode power of 500w, the lower electrode power of 200w; the etching gas is Cl 2 / BCl 3 , the ratio is about 20:1, and the etching depth is about 1.5um.

[0026] (4) The modification stage is to fully remove the GaN layer through excessive etching without affecting the bottom width, height, and m...

Embodiment 2

[0031] A method for recovering and reusing LED scrap substrates, comprising the following steps:

[0032] (1) Firstly rework the prepared scrap sheet completely, remove the film layer deposited during the preparation process by chemical corrosion and rinse with water to dry it.

[0033] (2) Fast engraving process Cl 2 / BCl 3 The / Ar ratio is about 10:2:1, the upper electrode power is 1000w, the lower electrode power is about 300w, and the etching depth is 5um.

[0034] (3) The lithography process removes GaN and at the same time removes the unevenness caused by fast etching, which effectively improves the appearance of PSS after regeneration. This process uses the upper electrode power of 500w, the lower electrode power of 200w; the etching gas is Cl 2 / BCl 3 , the ratio is about 20:1, and the etching depth is about 1.5um.

[0035] (4) The modification stage is to fully remove the GaN layer through excessive etching without affecting the bottom width, height, and morpholo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com