A hydraulic oil tank with oil-water separation

A hydraulic oil tank and oil-water separation technology, which is applied in the direction of oil supply tank devices, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problems of oil-water separation, poor effect, and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

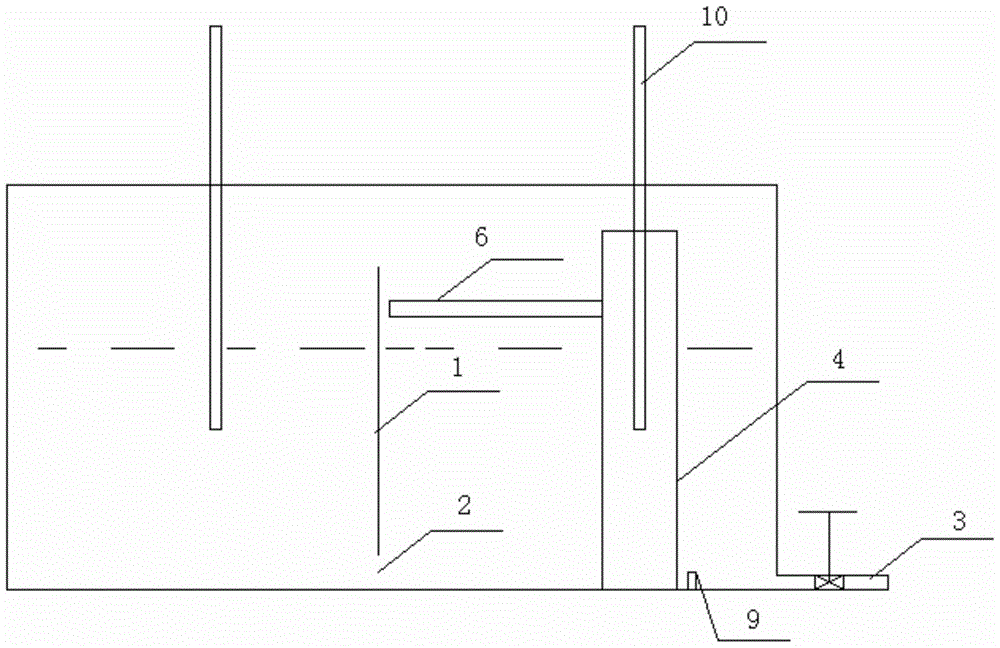

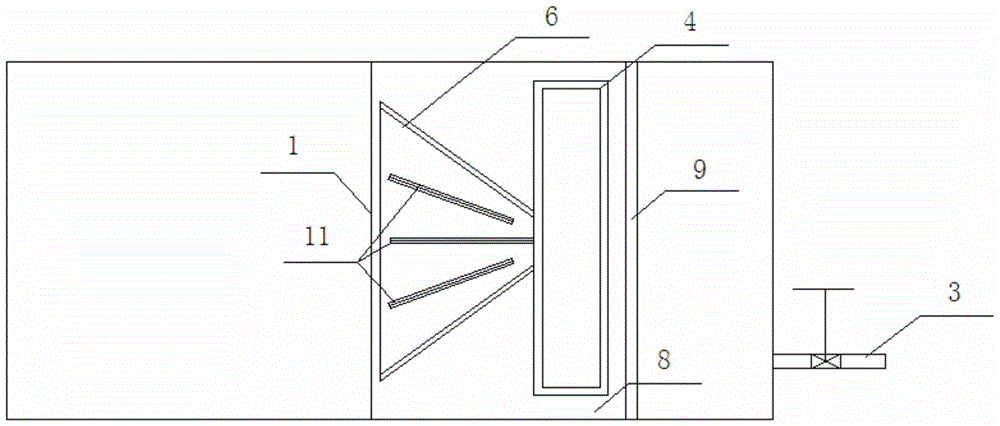

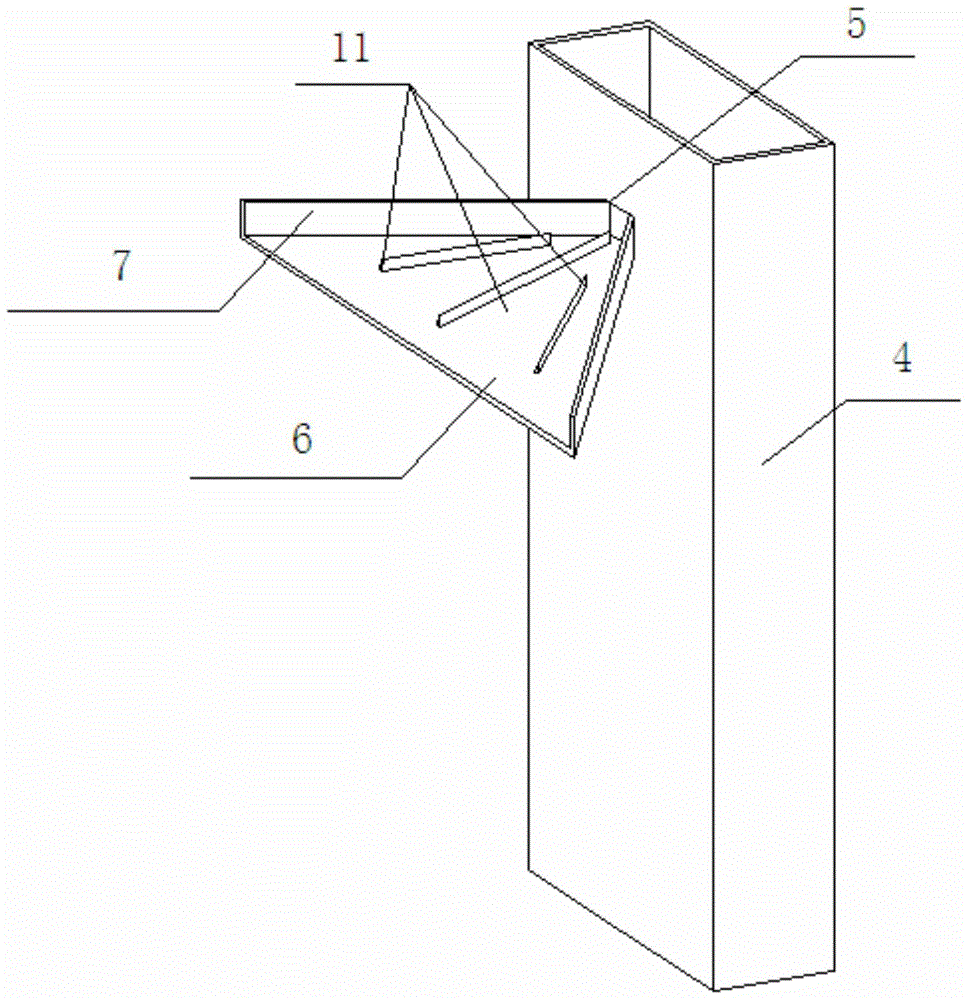

[0010] see figure 1 figure 2 image 3 , when the oil tank is working, different from the prior art, the oil in the oil return pipe 10 does not flow back into the oil return tank, but returns the oil to the oil return barrel 4 of the oil return tank. The oil in the barrel overflows through the opening 5 of the barrel wall and flows into the diffusion device 6. Due to the action of the column edge 7 erected upward along the corner of the welding surface on the diffusion device 6, and at the same time under the action of the diverter bar 11, the inflow is diffused. The oil surface in the device 6 expands into a plane, and the oil speed slows down. When the return oil flows out from the diffusion device 6 and flows downward against the partition 1 without impact, the generation of air bubbles is reduced. The above not only maintains the stability of oil convection, but also reduces the air bubbles on the oil surface, so that oil and water can be separated better. When the retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com