Screening equipment for processing environmentally degradable materials

A technology for degrading materials and screening equipment, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc. It can solve the problem of inconvenient discharge of impurities in the screen, and achieve the effects of easy screening and separation, strong practicability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

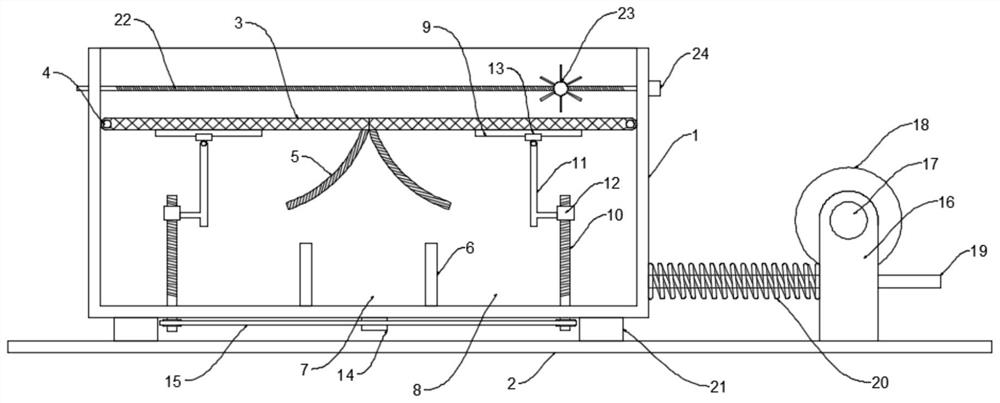

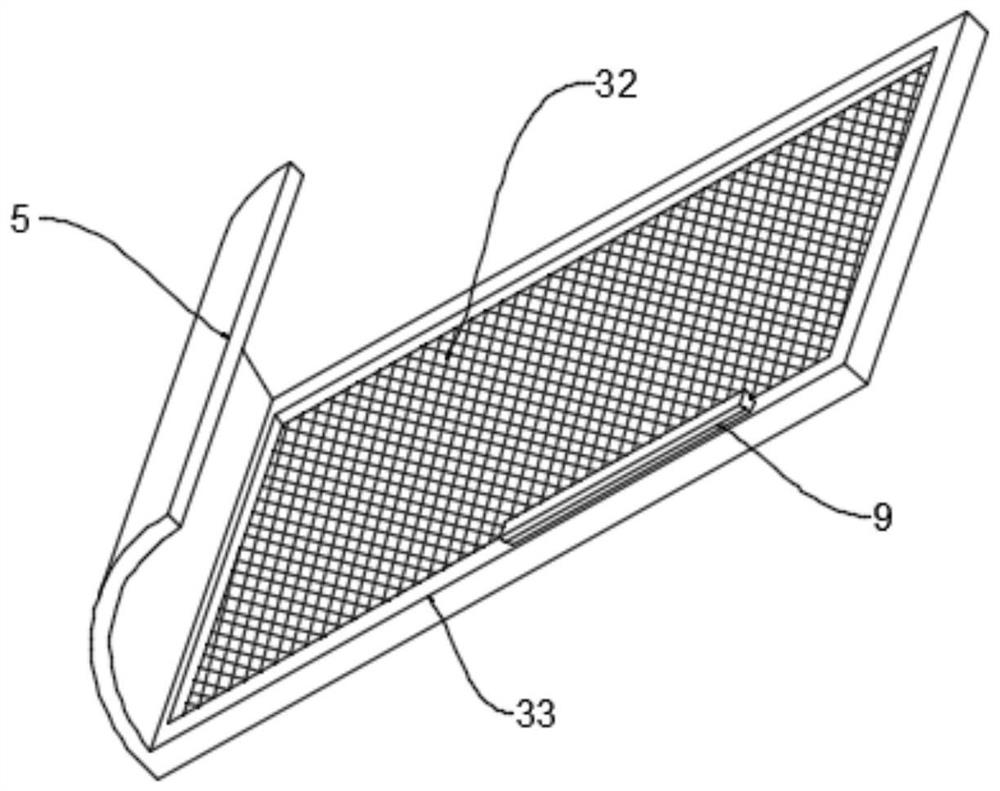

[0021] see figure 1 and 2 , in an embodiment of the present invention, a screening device for processing environmentally degradable materials, including a screening tank 1 and a base plate 2, two sieve plate parts 3 are arranged inside the screening tank 1 near the port, and two sieve plates Part 3 constitutes a screening plate horizontally, and the sides of the two sieve plate parts 3 close to the side wall of the screening tank body 1 are hinged to the side wall of the screening tank body 1 through the hinge seat 4, and the inside of the screening tank body 1 is also provided with a function to hold the screen plate parts 3 An adjustable support assembly that is held up and rotated. The sieve plate member 3 is composed of a screen mesh 32 and an outer frame 33 surrounding the outside. The two sieve plate members 3 are equipped with arc-shaped guide plates 5 at the bottom of the end. 1 The bottom wall is provided with two partitions 6, and the two partitions 6 divide the bot...

Embodiment 2

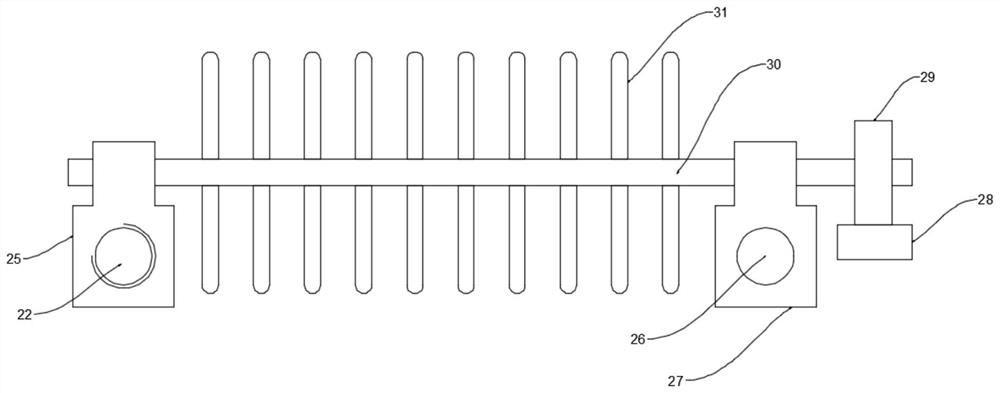

[0025] see figure 1 and 3 The difference between the embodiment of the present invention and embodiment 1 is that: the port of the screening tank body 1 is also provided with a turning assembly which is located on the sieve plate part 3 and turns the material on it, and the turning assembly includes a horizontal wire The rod 22, the limit slide bar 26 and the turning unit 23 arranged between the horizontal screw rod 22 and the limit slide bar 26, the end of the horizontal screw rod 22 is rotatably connected with the side wall of the screening tank body 1 and one end of the horizontal screw rod 22 is connected There is a turning motor 24, and the horizontal screw rod 22 is covered with a fixed screw sleeve 25, and the slide bar 26 is limited to be provided with a sliding seat 27. The turning motor 24 drives the horizontal screw rod 22 to rotate and utilizes the fixed screw sleeve 25 and the horizontal wire The cooperation of the rod 22 can drive the entire turning unit 23 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com