Bridge deck pavement block, bridge paved by same and manufacturing method of bridge deck pavement block

A technology for paving and bridges, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of easy formation of ruts, ruts, potholes, sliding, oil flooding, etc., to improve the resistance to deformation, improve mechanical strength, combine Powerful and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

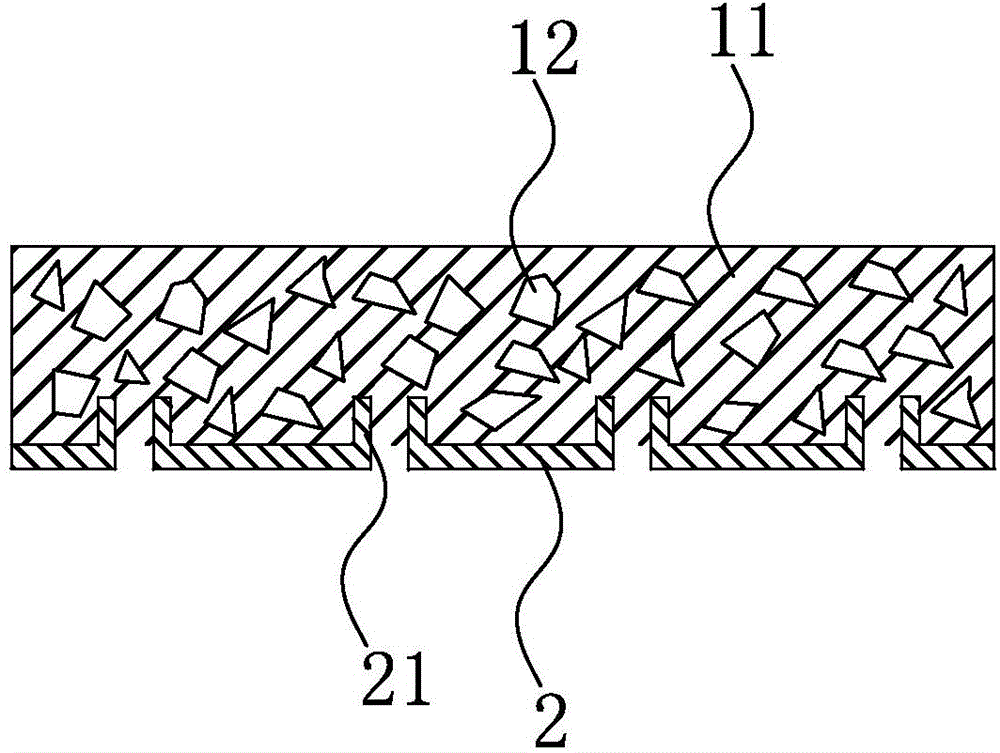

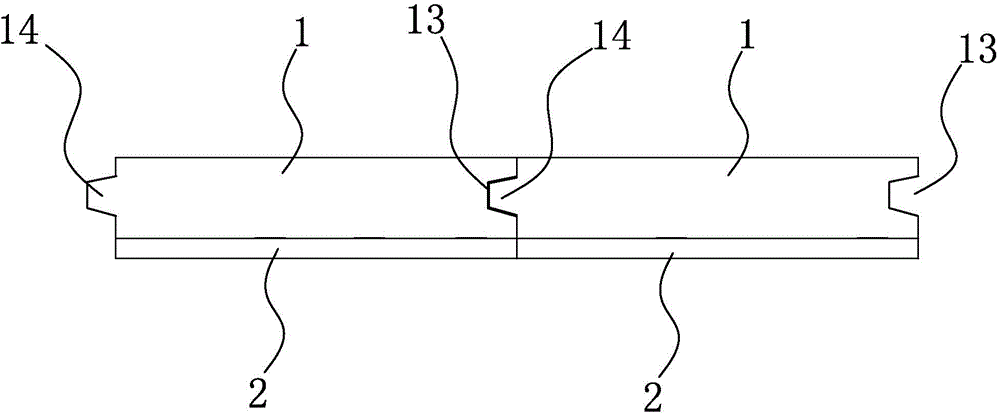

[0067] see Figure 1 to Figure 2 , according to the embodiment of the bridge deck pavement provided by the present invention, the pavement body 1 is made of composite rubber concrete or rubber asphalt concrete. The pavement body 1 made of composite rubber concrete or rubber asphalt concrete has better mechanical properties, high temperature stability, water stability, low temperature crack resistance, durability, aging resistance, and deformation resistance than traditional bridge deck pavement structures. etc. have been greatly improved, and have the characteristics of light weight, long service life, fatigue cracking resistance, etc., which better solve the problems of sliding, pushing, cracking, pits, ruts and bulges in the current bridge deck pavement structure. It can be applied to all kinds of hard bridge deck paving.

[0068] see Figure 1 to Figure 2 , according to the above-mentioned embodiment of the present invention, further includes a base plate arranged at the ...

Embodiment 2

[0082] This embodiment is roughly the same as the above-mentioned embodiment one, and the difference is that the composite rubber described in this implementation contains the following substances and parts by weight:

[0083]

Embodiment 3

[0085] This embodiment is roughly the same as the above-mentioned embodiment one, and the difference is that the composite rubber described in this implementation contains the following substances and parts by weight:

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com