Method for producing succinic acid by taking sugarcane bagasse as raw materials through fermentation

A technology of bagasse and succinic acid is applied in the field of bioengineering, which can solve the problems of increased cost and low yield, and achieve the effects of increasing concentration, protecting the environment, and requiring low fermentation equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

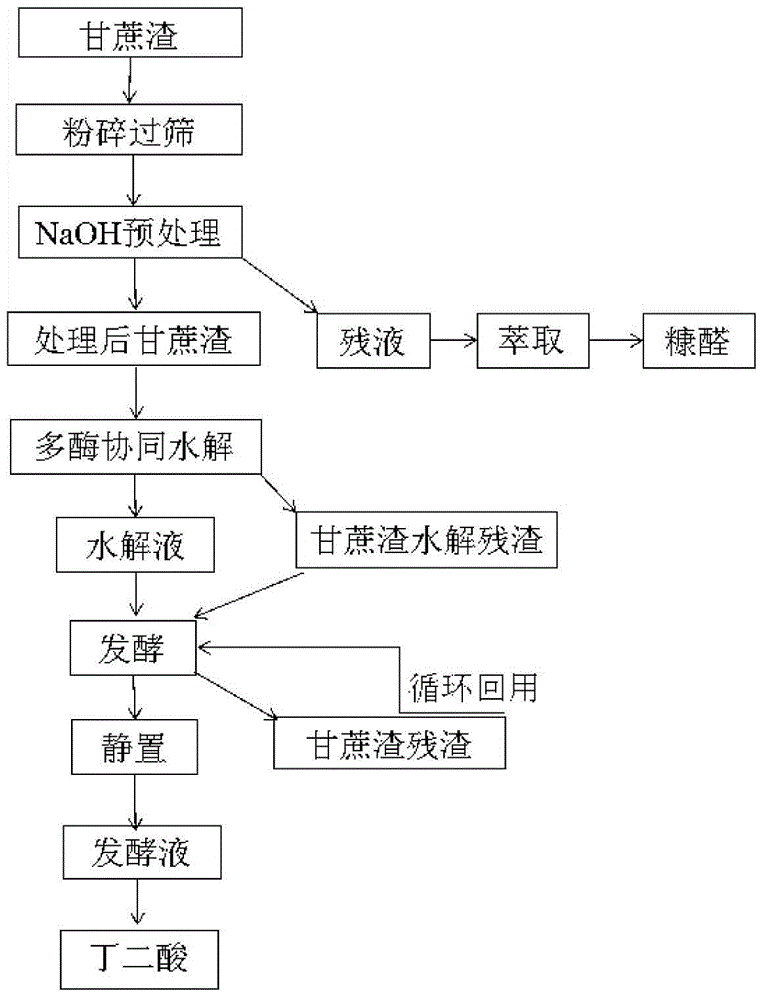

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: dilute alkali pretreatment bagasse

[0035] Take 20 g of crushed and dried bagasse, mix it with 300 mL of NaOH solution with a mass concentration of 1%, pretreat the bagasse at a high temperature of 121°C for 2 hours, filter and wash the bagasse until neutral, and dry at 65°C to obtain 13g of pretreated bagasse. The processed bagasse has a weight loss of 35%, a total cellulose content of 87.6%, and its composition is shown in Table 1.

[0036] Table 1 Components of alkaline pretreated bagasse measured by NREL method

[0037]

Embodiment 2

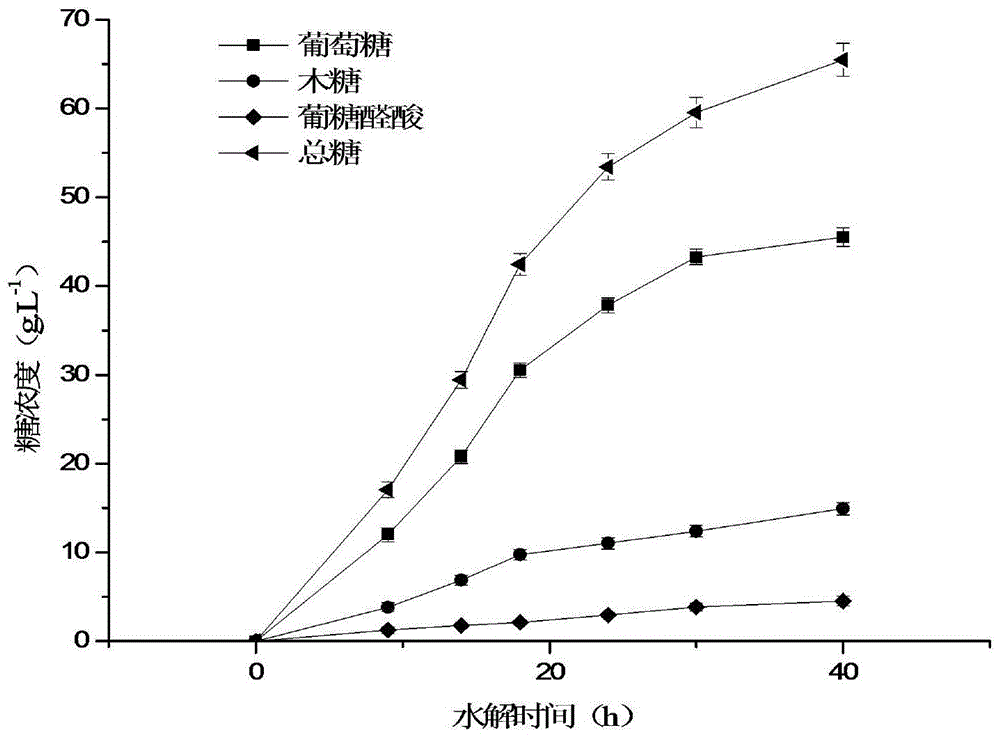

[0038] Example 2: Multi-enzyme synergistic hydrolysis of bagasse after alkali treatment

[0039] Weigh 3g of the bagasse that has been pretreated with alkali, transfer it to a 150mL conical flask, add cellulase 25FPU.g -1 , Xylanase 85U.g -1 , β-glucanase 40U.g -1 , Pectinase 25U.g -1 , add pH 5.0 citric acid buffer solution, set the volume to 40mL, perform hydrolysis on a water bath shaker at 50°C for 40h, and take a sample every 4h. Multi-enzyme synergistic hydrolysis time figure 2 . After 40 hours of hydrolysis, the reducing sugar concentration in the hydrolyzate is 65.6g.L -1 , the total cellulose hydrolysis efficiency of bagasse reaches up to 90%, and the concentration of glucose in bagasse hydrolyzate is 45.06g.L -1 , the concentration of xylose is 14.92g.L -1 , the concentration of glucuronic acid is 5.62g.L -1 , the concentration ratio of glucose and xylose is close to 3:1. The multi-enzyme synergistic hydrolysis pretreatment time curve of bagasse is as follo...

Embodiment 3

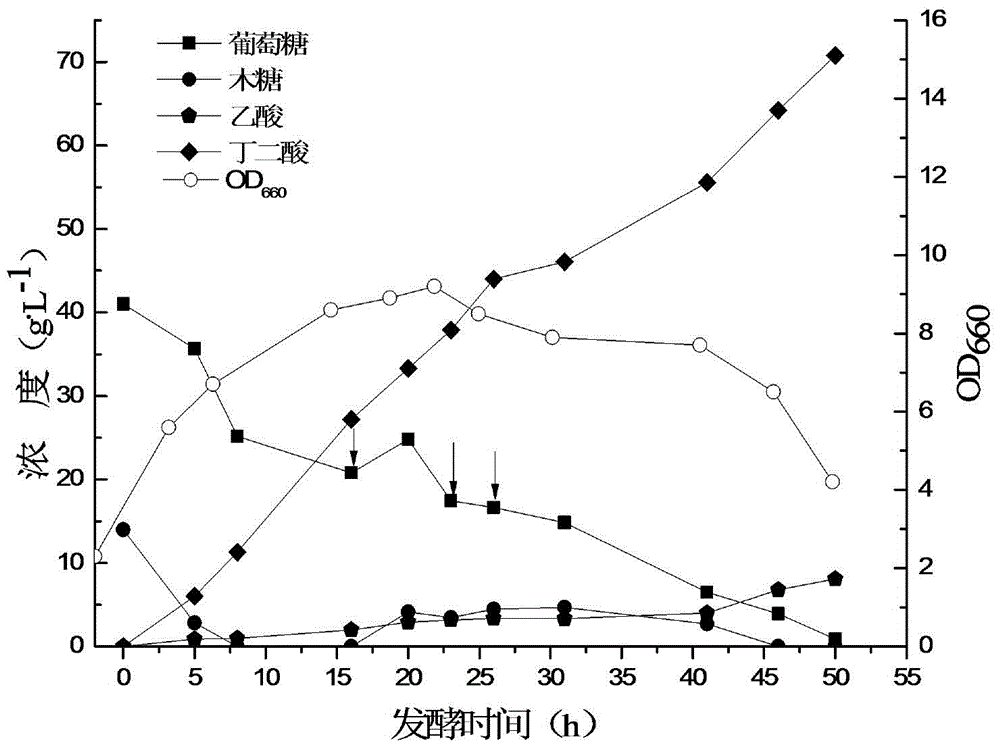

[0040] Embodiment 3: sugarcane bagasse hydrolyzate fed-batch fermentation produces succinic acid

[0041] Strain: Actinobacillus ssuccinogenes F3-21. Medium: bagasse hydrolyzate sugar concentration 55g.L -1 , corn steep liquor concentration 25g.L -1 , anhydrous calcium chloride concentration 0.2g.L -1 , dipotassium hydrogen phosphate concentration 2g.L -1 , sodium dihydrogen phosphate concentration 9.6g.L -1 , magnesium chloride hexahydrate concentration 0.2g.L -1 , sodium sulfide concentration 0.1g.L -1 , adjust the pH to 6.0, and sterilize at 121°C for 20 minutes.

[0042] In a 3L stirred fermenter, fed-batch fermentation is adopted, and the concentration of the initial bagasse hydrolyzed sugar solution is 55g.L -1 , when the residual sugar concentration in the fermentation broth drops to 20g.L -1 When using a peristaltic pump, add the total reducing sugar concentration to 200g.L -1 The concentrated sugar cane bagasse is hydrolyzed to control the sugar concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com