High-temperature antioxidant and preparation method thereof, and applications of high-temperature antioxidant in gear oil

A high-temperature antioxidant and gear oil technology, applied in the field of lubricating oil, can solve problems such as poor gear shifting of synchronizers, oil seal wear and oil leakage, and carbon on the surface of gears, so as to improve anti-oxidation ability, reduce oil seal wear, and prolong The effect of the oil change interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

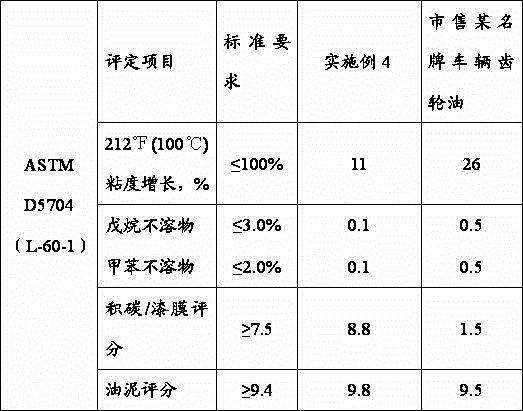

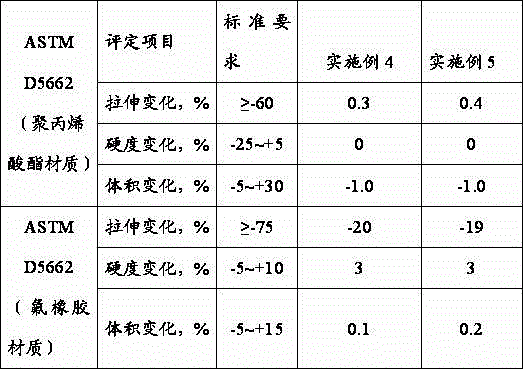

Examples

Embodiment 1

[0044] Example 1, this example provides a high-temperature antioxidant (2,2'-thiobis-p-tertylphenol alkenyl succinate copper) including the following specific steps:

[0045] In a 500mL four-neck flask equipped with a thermometer sleeve, a stirrer, a reflux condenser and a dropping funnel, add 0.45mol p-tetylphenol and 320mL n-hexane to form a suspension, stir and cool down to 0-15°C , drop 32.6g of sulfur dichloride into the reaction flask through the dropping funnel, drop it for about 1.50h, absorb the hydrogen chloride gas generated by the reaction with water, continue to stir at this temperature for 1h, filter out the precipitate, first use 60mL of n-hexane Washing, washing with water, and drying to obtain the white product 2,2'-thiobis-p-tetraoctylphenol.

[0046] Add about 0.25mol of alkenyl succinic acid phenol and 40mL of benzene into the container, mix and stir, heat to 80°C and protect with nitrogen, add 2,2,-thiobis-p-tetraoctylphenol benzene solution dropwise, Af...

Embodiment 2

[0048] Example 2, this example provides a high temperature antioxidant (2,2'-thiobis-p-tertylphenol alkenyl succinate copper) including the following specific steps:

[0049] In a 500mL four-neck flask equipped with a thermometer sleeve, a stirrer, a reflux condenser and a dropping funnel, add 0.40mol p-tertylphenol and 300mL n-hexane to form a suspension, stir and cool down to 0-15°C , drop 31g of sulfur dichloride into the reaction flask through the dropping funnel, drop it in about 1.50h, absorb the hydrogen chloride gas produced by the reaction with water, continue to stir at this temperature for 1h, filter out the precipitate, and wash it with 57mL of n-hexane , and then washed with water and dried to obtain the white product 2,2'-thiobis-tetraoctylphenol.

[0050] Add about 0.22mol of alkenyl succinic acid phenol and 35mL of benzene into the container, mix and stir, heat to 80°C and protect with nitrogen, add 2,2,-thiobis-p-tetraoctylphenol benzene solution dropwise, A...

Embodiment 3

[0052] Embodiment 3, this embodiment provides a high-temperature antioxidant (2,2'-thiobis-p-tertylphenol alkenyl succinate copper) including the following specific steps:

[0053] In a 500mL four-necked flask equipped with a thermometer sleeve, a stirrer, a reflux condenser and a dropping funnel, add 0.5mol p-tertylphenol and 340mL n-hexane to form a suspension, stir and cool down to 0-15°C , drop 34g of sulfur dichloride into the reaction bottle through the dropping funnel, drop it in about 1.50h, absorb the hydrogen chloride gas generated by the reaction with water, continue to stir at this temperature for 1h, filter out the precipitate, and wash it with 70mL of n-hexane , and then washed with water and dried to obtain the white product 2,2'-thiobis-tetraoctylphenol.

[0054] Add about 0.3mol of alkenyl succinic acid phenol and 50mL of benzene into the container, mix and stir, heat to 80°C and protect with nitrogen, add 2,2,-thiobis-p-tert-octylphenol benzene solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com