Solvent type polyurethane structure adhesive and preparation method thereof

A polyurethane and adhesive technology, applied in the field of polyurethane materials, can solve the problems of toxic unblocking agents, etc., and achieve the effects of good operating performance, energy saving, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 50.00 grams of PCL (M n =2000) into a 500mL three-necked flask, dehydrated at 115°C for 1 hour and then cooled to 60°C. Take 0.04 g of DBTDL, 18 g of TDI and 30 g of butanone into a three-necked flask, stir and react at 80°C for 2 hours, then add 12 g of PHE and react at 80°C for 5 hours to obtain a blocked polyurethane prepolymer (component A).

[0043] Then 3 grams of TMP, 3.3 grams of CO and 10 grams of ethyl acetate were mixed uniformly to obtain component B, and then mixed with 0.1 grams of 2,6-di-tert-butyl-p-cresol, 0.5 grams of KH560, 7 grams of nano-silica, The above-mentioned closed polyurethane prepolymer is stirred and mixed uniformly to obtain a solvent-type polyurethane structural adhesive.

[0044] According to actual construction needs, the ratio of component A and component B can also be adjusted to obtain adhesives with different bonding strengths and thermodynamic properties.

Embodiment 2

[0046] 80.00 grams of PEA (M n =2000) into a 500mL three-necked flask, dehydrated at 115°C for 1 hour and then cooled to 60°C. Take 0.04 g of DBTDL, 10 g of MDI and 70 g of butanone into a three-necked flask, stir and react at 70°C for 2 hours, then add 0.95 g of DEG, and react at 60°C for 5 hours to obtain a hydroxyl-terminated polyurethane prepolymer.

[0047] Then add 6.25 grams of HDIT, 1.40 grams of PHE, 0.02 grams of DBTDL and 10 grams of butyl acetate into a 50mL three-necked flask, react at 85°C for 3 hours under stirring conditions to obtain a blocked isocyanate curing agent, and then stir and mix with the above polyurethane prepolymer After uniformity, a solvent-based polyurethane structural adhesive is obtained.

[0048] According to actual construction needs, the ratio of the two components can also be adjusted to obtain adhesives with different bonding strengths and thermodynamic properties.

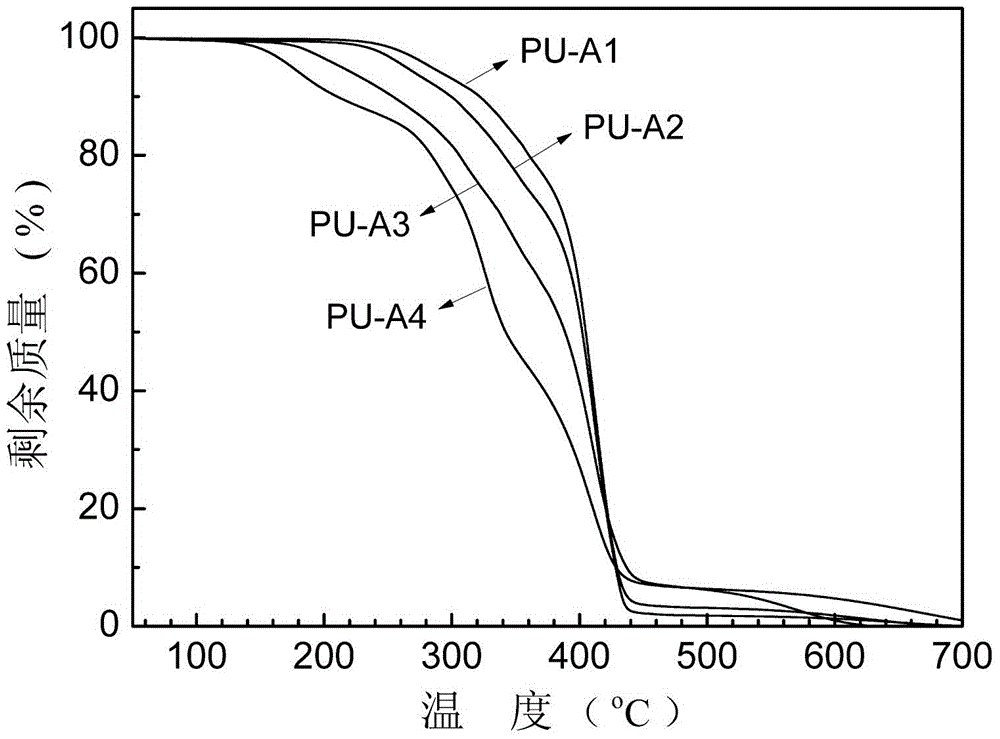

[0049] If other conditions of this embodiment remain unchanged, and D...

Embodiment 3

[0052] 50.00 grams of PBA (M n =3200) into a 500mL three-neck flask, dehydrated at 115°C for 1 hour and then cooled to 60°C. 0.02 g of DBTDL, 2.72 g of TDI and 55 g of methyl ethyl ketone were added into a three-necked flask, stirred and reacted at 80° C. for 2 hours to obtain a hydroxyl-terminated polyurethane prepolymer PU-CA.

[0053] Then, take 80 grams of TDI and 230 mL of methyl ethyl ketone and add them to a 500 mL three-necked flask, raise the temperature to 65 ° C, add 20.5 grams of TMP under stirring, complete the addition within 2 hours, keep warm at 70 ° C for 2 hours, and then add 51.9 grams of PHE , react at 80°C for 4 hours, and cool to room temperature to obtain blocked isocyanate curing agent PU-CA.

[0054] Finally, according to construction requirements, a certain proportion of blocked isocyanate curing agent and the above polyurethane prepolymer are stirred and mixed evenly to obtain a solvent-based polyurethane structural adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

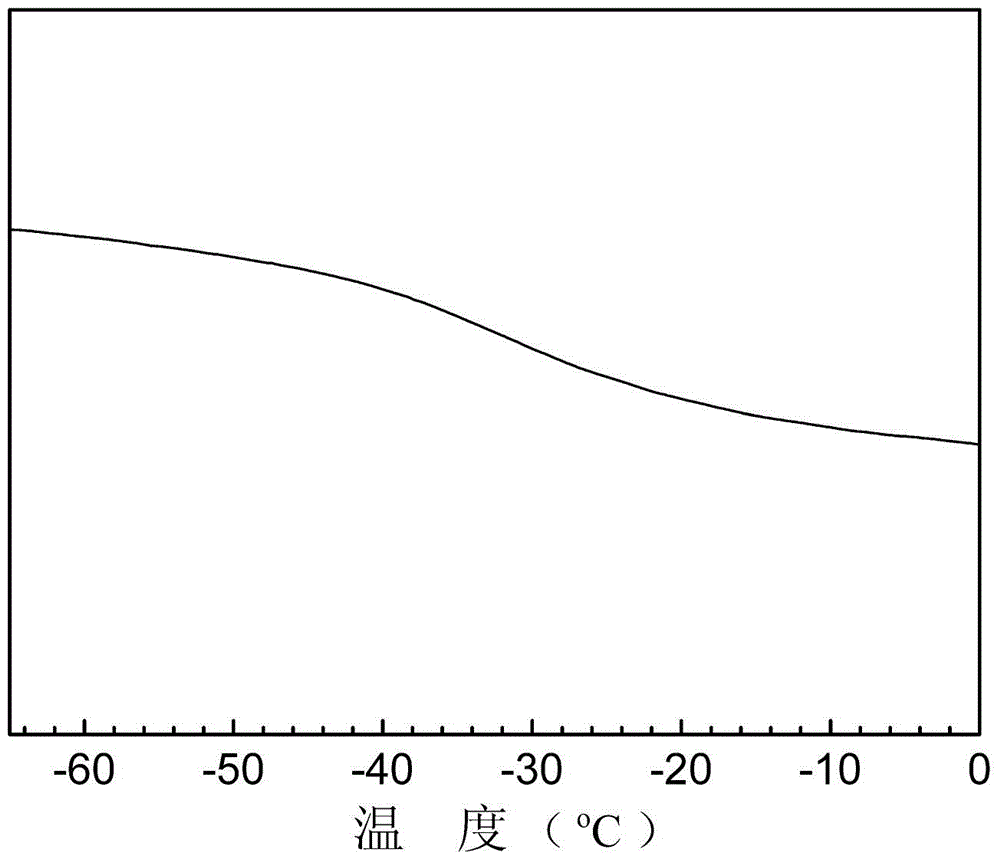

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com