Preparation method for rubber peptizer DBD

A technology of rubber peptizer and aminobenzene, which is applied in the field of synthesis of chemical raw materials, can solve the problems of low yield and complicated process, and achieve the effects of high productivity, simple process flow and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

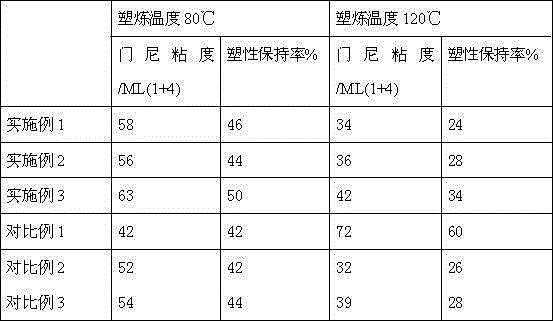

Examples

Embodiment 1

[0019] First prepare p-aminobenzothiazole:

[0020] Heat the water bath to 50~55°C, weigh 10ml of toluene ethanol solution, dilute it 50 times, prepare a diluted toluene solution, then pour 3g of p-aminoacetanilide crystals, stir, and wait until the aminoacetanilide crystals are completely dissolved in the toluene solution, Toluene solution is an excellent organic solvent; after the temperature is stable, slowly add 5-7 drops of concentrated sulfuric acid, and stir until a suspension is formed; the temperature of the water bath is raised to 70-75°C, and 5g of sodium thiocyanate is weighed Add the solid to the suspension, stir, then add 10ml of benzoyl chloride solution, stir to react; wash with water, dry, and distill off the solvent to obtain needle crystals. This step mainly utilizes p-aminoacetanilide and sodium thiocyanide as the main reactants, and the yield is 68%.

[0021] Then prepare 2,2′-diphenylamine disulfide:

[0022] Weigh 5g of synthesized 2-aminobenzothiazole...

Embodiment 2

[0026] First prepare p-aminobenzothiazole:

[0027] Heat the water bath to 50~55°C, weigh 5ml of toluene in ethanol, dilute 50 times to prepare a diluted toluene solution, then pour 2.1g of p-aminoacetanilide crystals, stir until the aminoacetanilide crystals are completely dissolved in the toluene solution , toluene solution is an excellent organic solvent; after the temperature is stable, slowly add 5-7 drops of concentrated sulfuric acid, and stir until a suspension is formed; the temperature of the water bath is raised to 70-75°C, and 4.3g of thiocyanate is weighed Sodium chloride solid was added to the suspension, stirred, and then 8ml of benzoyl chloride solution was added, stirred and reacted; washed with water, dried, and distilled off the solvent to obtain needle crystals. This step mainly utilizes p-aminoacetanilide and sodium thiocyanide as the main reactants, and the yield is 66%.

[0028] Then prepare 2,2′-diphenylamine disulfide:

[0029] Weigh 5.3g of synthesi...

Embodiment 3

[0033] First prepare p-aminobenzothiazole:

[0034] Heat the water bath to 50~55°C, weigh 5.6ml of toluene in ethanol, dilute 50 times to prepare a diluted toluene solution, then pour 3g of p-aminoacetanilide crystals, stir until the aminoacetanilide crystals are completely dissolved in the toluene solution , toluene solution is an excellent organic solvent; after the temperature is stable, slowly add 5-7 drops of concentrated sulfuric acid, and stir until a suspension is formed; the temperature of the water bath is raised to 70-75°C, and 3.2g of thiocyanate is weighed Sodium chloride solid was added to the suspension, stirred, and then 10ml of benzoyl chloride solution was added, stirred and reacted; washed with water, dried, and distilled off the solvent to obtain needle crystals. This step mainly utilizes p-aminoacetanilide and sodium thiocyanide as the main reactants, and the yield is 68%.

[0035] Then prepare 2,2′-diphenylamine disulfide:

[0036] Weigh 3.6g of synthes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com