Preparation method of silicon nitride-based self-lubricating ceramic cutter material containing alumina-coated hexagonal boron nitride composite powder

A technology of hexagonal boron nitride and composite powder, which is applied in the field of preparation of silicon nitride-based self-lubricating ceramic tool materials, can solve problems such as inapplicability, and achieve improved mechanical properties, fracture toughness and flexural strength, and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

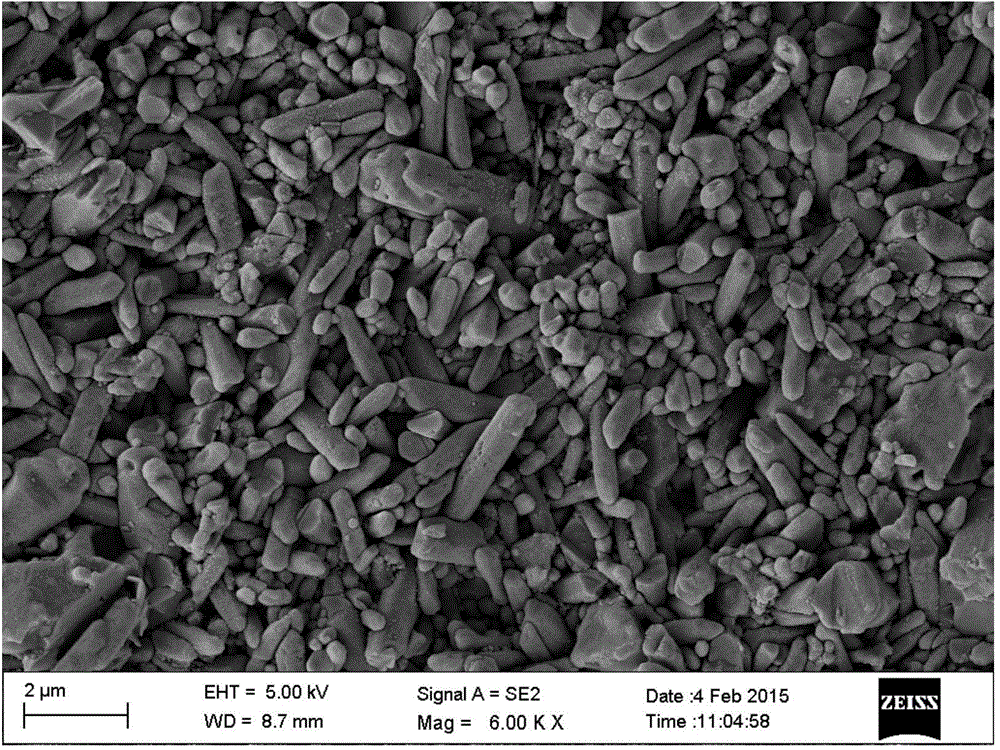

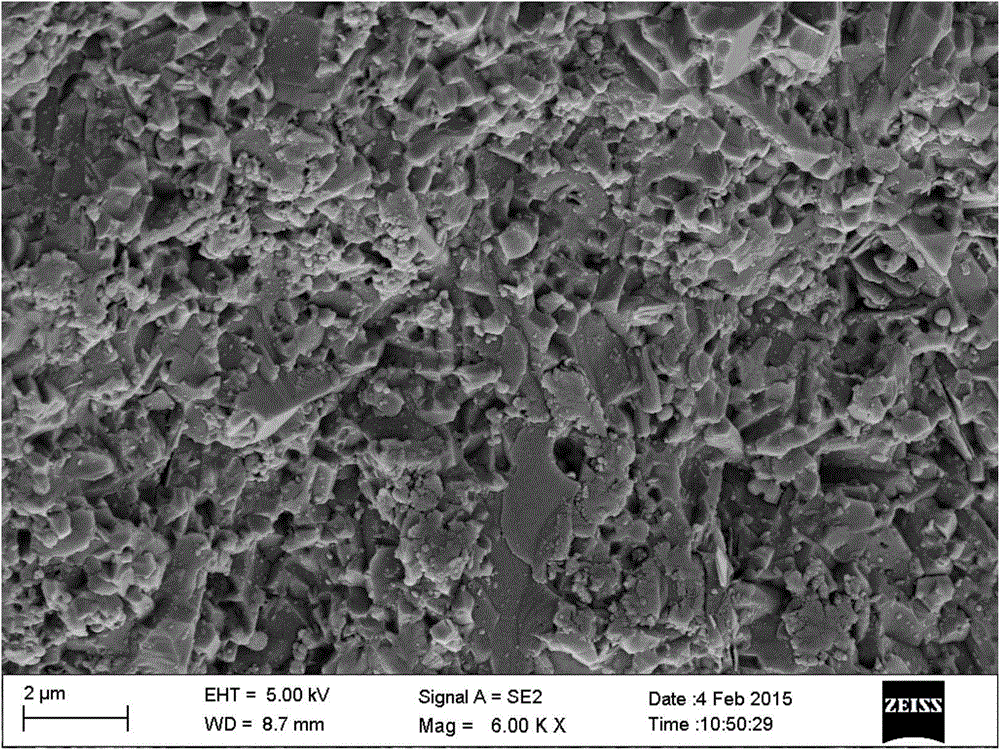

[0033] Adding aluminum oxide-coated hexagonal boron nitride composite powder, silicon nitride-based self-lubricating ceramic tool material, the volume percentage of each raw material component is micron silicon nitride (α-Si 3 N 4 )62%, nano-silicon nitride (α-Si 3 N 4 ) 10%, micron titanium carbide 10%, alumina 3.2%, yttrium oxide 4.8%, alumina-coated hexagonal boron nitride 10%.

[0034] In proportion, weigh micron silicon nitride (α-Si 3 N 4 ), nano silicon nitride (α-Si 3 N 4 ), micron titanium carbide, aluminum oxide, yttrium oxide. Use an appropriate amount of absolute ethanol as the dispersion medium, respectively configure micron silicon nitride, micron titanium carbide suspension and nano silicon nitride suspension, and ultrasonically disperse for 15 minutes while fully stirring. The obtained micron silicon nitride, micron titanium carbide suspension and nano silicon nitride suspension were mixed, then aluminum oxide and yttrium oxide were added to prepare a mi...

Embodiment 2

[0039] Silicon nitride-based self-lubricating ceramic tools with aluminum oxide-coated hexagonal boron nitride powder added, the volume percentage of each raw material component is micron silicon nitride (α-Si 3 N 4 )67%, nano-silicon nitride (α-Si 3 N 4 ) 10%, micron titanium carbide 10%, alumina 3.2%, yttrium oxide 4.8%, alumina-coated hexagonal boron nitride 5%.

[0040] In proportion, weigh micron silicon nitride (α-Si 3 N 4 ), nano silicon nitride (α-Si 3 N 4 ), micron titanium carbide, aluminum oxide, yttrium oxide. Use an appropriate amount of absolute ethanol as the dispersion medium, respectively configure micron silicon nitride, micron titanium carbide suspension and nano silicon nitride suspension, and ultrasonically disperse for 15 minutes while fully stirring. The obtained micron silicon nitride, micron titanium carbide suspension and nano silicon nitride suspension were mixed, then aluminum oxide and yttrium oxide were added to prepare a mixed suspension, ...

Embodiment 3

[0044] The volume percentage of each raw material component of silicon nitride-based self-lubricating ceramic tools with alumina-coated hexagonal boron nitride powder is micron silicon nitride (α-Si 3 N 4 )57%, nano-silicon nitride (α-Si 3 N 4 ) 10%, micron titanium carbide 10%, alumina 3.2%, yttrium oxide 4.8%, alumina-coated hexagonal boron nitride 15%.

[0045] In proportion, weigh micron silicon nitride (α-Si 3 N 4 ), nano silicon nitride (α-Si 3 N 4 ), micron titanium carbide, aluminum oxide, yttrium oxide. Use an appropriate amount of absolute ethanol as the dispersion medium, respectively configure micron silicon nitride, micron titanium carbide suspension and nano silicon nitride suspension, and ultrasonically disperse for 15 minutes while fully stirring. The obtained micron silicon nitride, micron titanium carbide suspension and nano silicon nitride suspension were mixed, then aluminum oxide and yttrium oxide were added to prepare a mixed suspension, fully stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com