High-efficiency welding wheel grinding device and grinding method

A welding wheel and high-efficiency technology, which is used in grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems that affect the quality of the welding wheel, affect the production efficiency, and virtual welding of the welding wheel, so as to reduce the defect of the welding seam. problems, improve quality and stability, reduce the effect of welding current shunting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

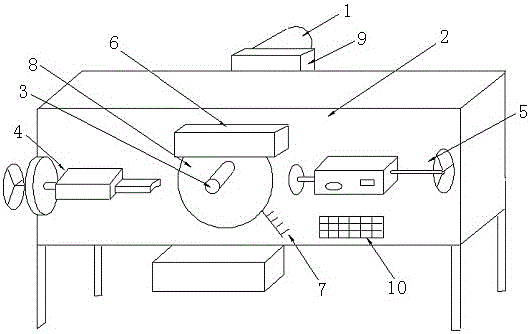

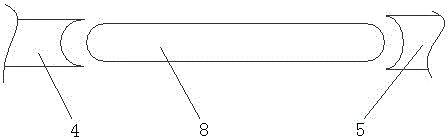

[0022] Such as figure 1 As shown, a high-efficiency welding wheel grinding device includes a drive motor 1, a grinding reference platform 2, a grinding rotating shaft 3, a grinding tool assembly 4, and a strengthening wheel assembly 5, the grinding tool assembly 4 and the strengthening wheel The assembly 5 is installed on the grinding reference platform 2, and the grinding rotation shaft 3 is vertically hinged on the grinding reference platform 2. In the present invention, in order to control the speed, the driving motor 1 is driven by a multi-stage gearbox 9 The grinding rotating shaft 3 rotates, and the shaft center of the grinding wheel 8 is opened with a through hole. After the grinding rotating shaft 3 passes through the through hole, the grinding wheel 8 is locked and fixed on the grinding wheel by a locking hydraulic nut. On the shaft 3; the grinding reference platform 2 is also equipped with a cooling mechanism 6 and a welding wheel diameter scale line 7. The cooling mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com