On-line monitoring device and method for motion state of broach

A motion state and monitoring device technology, which is applied in the field of mechanical cutting, can solve the problems of lack of monitoring of the motion state of the broach and the inability to obtain the number of processed workpieces, etc., and achieve the effects of low installation environment requirements, small size, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

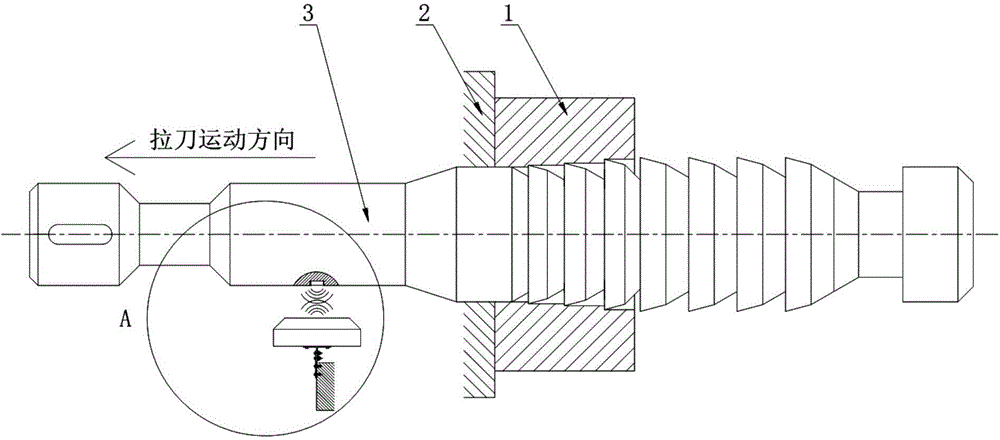

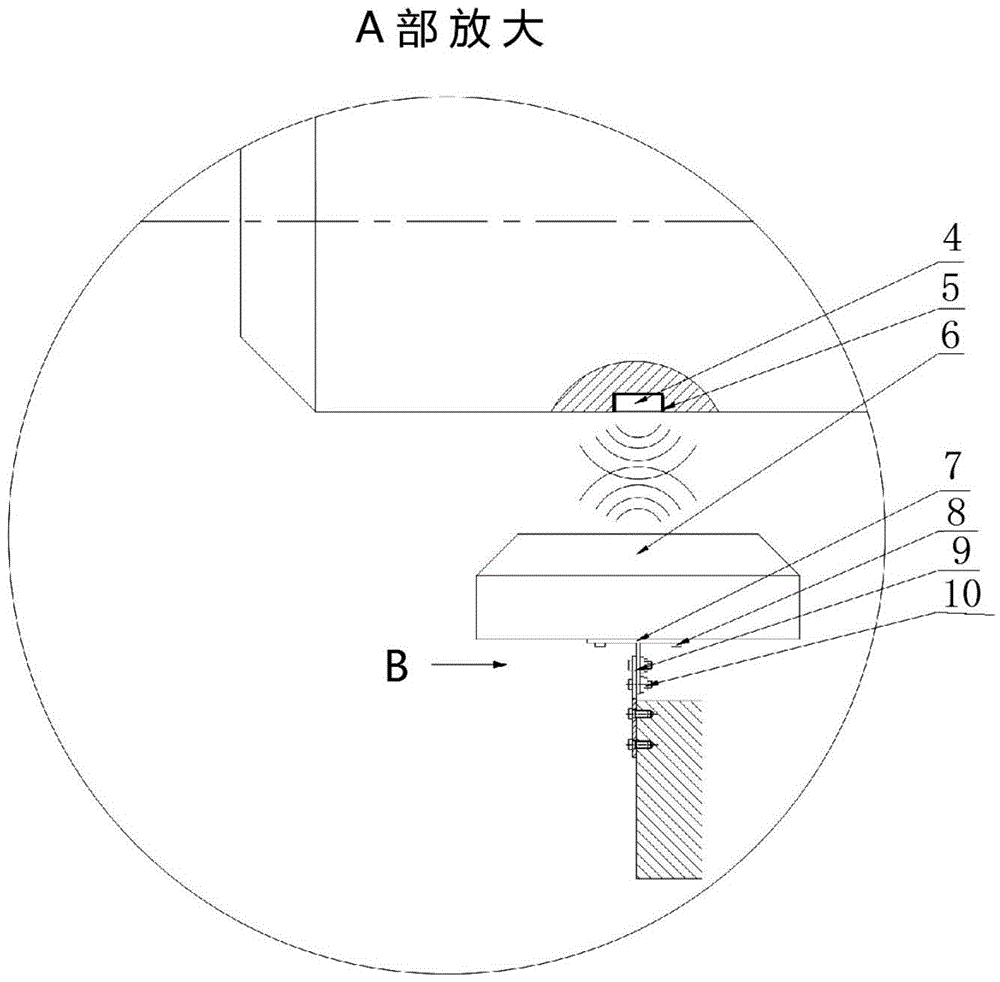

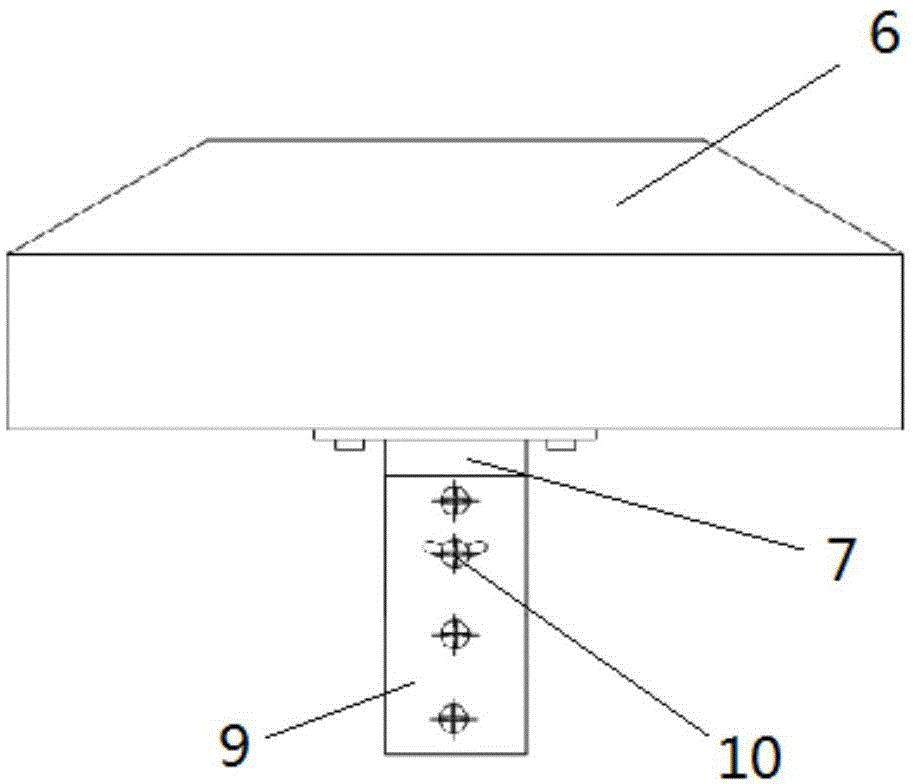

[0026] The invention is a device for long-term continuous monitoring of broach movement in broaching. It transmits motion information based on the principle of radio frequency identification. By installing the monitoring device on the broach and the machine tool, the tool life cycle Long-term continuous monitoring of broach movement; specifically, the passive anti-metal tag embedded in the handle of the broach is used as a data storage chip, and then the anti-metal tag is read and written through the ultra-high frequency reader installed inside the machine tool Operation, to achieve long-term continuous broach motion information collection. The whole set of device can automatically identify the label and write specific data through the embedded program design, without the support of the host, it can be directly installed inside the machine tool, and can ensure long-term, continuous and accurate broach movement monitoring.

[0027] Below in conjunction with embodiment and accom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com