A multifunctional casting loose sand furnace

A loose sand furnace and multi-functional technology, which is applied in the field of residual sand cleaning equipment in investment casting, can solve the problems of no filter device, no pressure control device, and inability to clean it out, so as to improve the utilization rate and service life, and the temperature is as fast as possible. Uniform and stable effect to improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

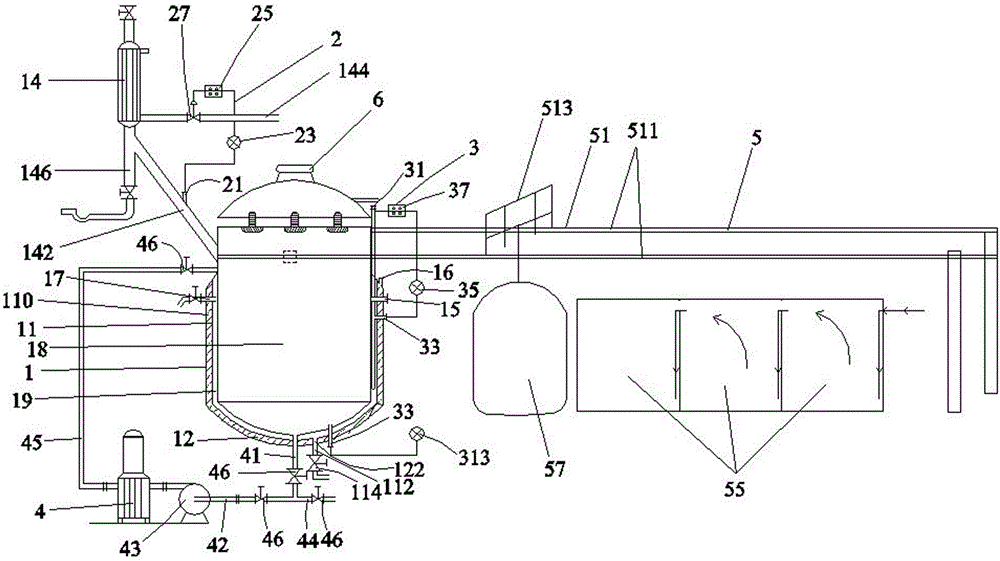

[0070] see Figure 1 to Figure 7 , a multifunctional sand casting furnace, including a vertical reaction kettle 1, a pressure control device 2, a heating temperature control display device 3, a filter device 4, a load rinsing device 5, and an end cover opening and closing device 6.

[0071] The vertical reactor 1 includes a vertical cylinder 11 , a lower head 12 installed at the bottom of the cylinder 11 and a reflux condenser 14 installed at the top of the cylinder 11 .

[0072] A connection pipe 142 is connected between the reflux condenser 14 and the barrel 11 .

[0073] The reflux condenser 14 is equipped with a water inlet pipe 144 and an absorption pipe 146 .

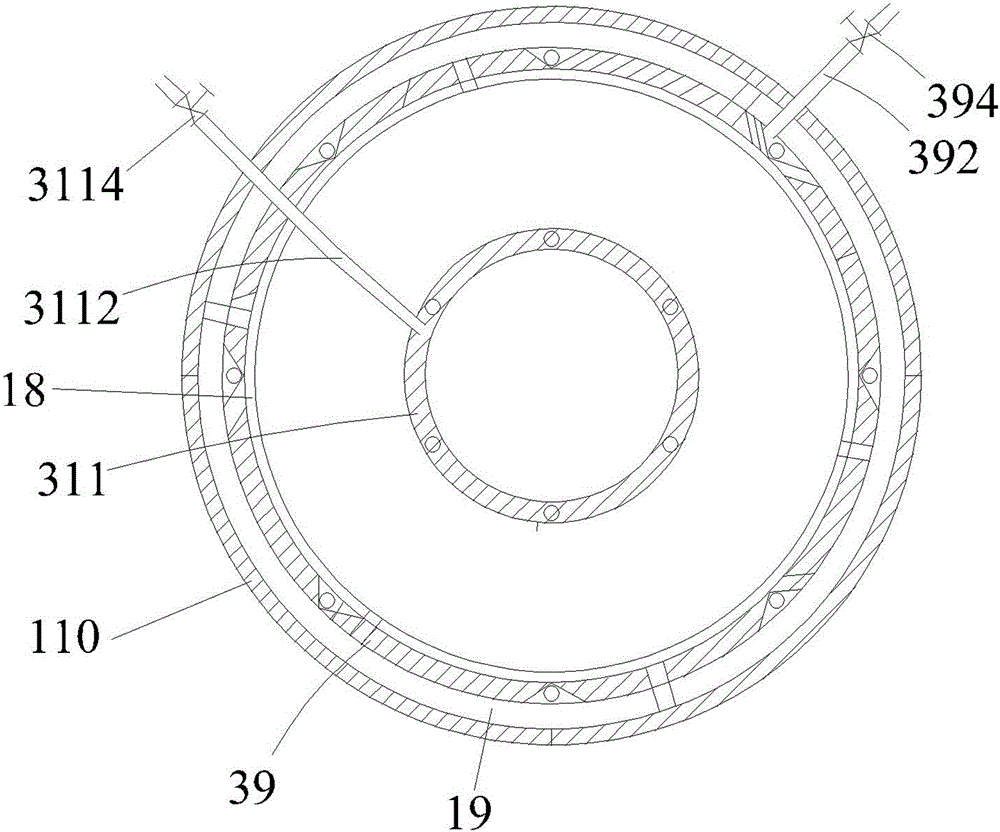

[0074] The vertical reactor 1 adopts a jacketed oil bath method for heat conduction. The vertical reactor 1 includes an inner cavity 18 , an intermediate layer 19 and an outer layer 110 arranged from the inside to the outside.

[0075] The inner chamber 18 is filled with working fluid (loose sand agent) and cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com