Temperature control method for slurry bed reactor, design method and application thereof

A technology of reactor and slurry bed, which is applied in the field of temperature control of slurry bed reactor, can solve the problems of reaction progress, uneven density, destruction of reaction balance, unfavorable reaction, etc., achieve uniform reactants and temperature, and increase cooling effect , Improve the effect of running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the content of the present invention, it will be described in conjunction with the accompanying drawings and specific embodiments.

[0029] This embodiment is a hydrogenation method and a temperature control method involved in the oil-coal mixing process. The hydrogenation reactor is a secondary stage. The specific process is as follows:

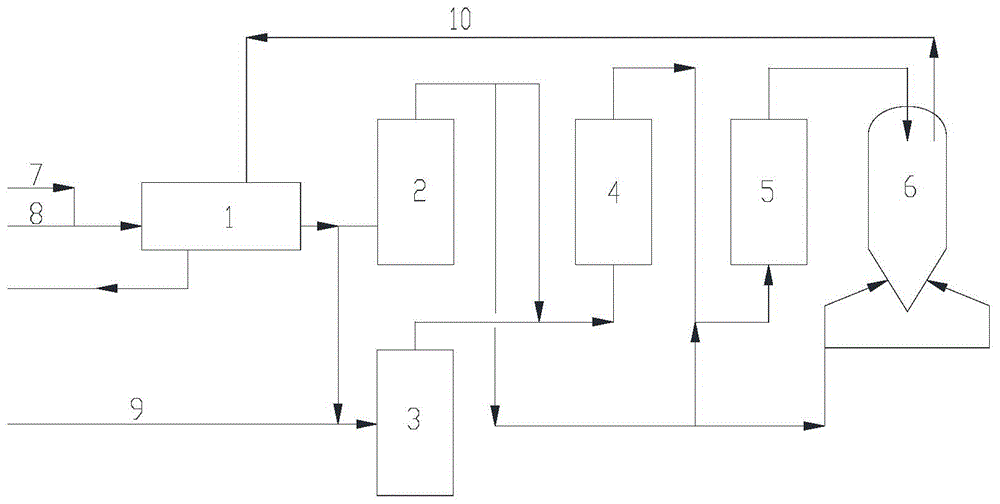

[0030] like figure 1 As shown, after the supplementary hydrogen 7 is mixed with the circulating hydrogen 8, it exchanges heat with the outlet gas of the high temperature and high pressure separator 6, that is, the hot high-fraction gas 10 at the hydrogen high-fraction gas heat exchanger 1 to raise the temperature to hydrogen at 425°C. Then 20% of the hydrogen is mixed with the oil-coal slurry feed 9 and enters the mixture flow that is heated to 365°C in the raw material heating furnace 3, and 80% of the hydrogen enters the high-temperature hydrogen that is heated to 535°C in the hydrogen heating furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com