Method for preparing high-performance B-ZSM-5 molecular sieve membrane in dilute synthesis solution

A technology of B-ZSM-5 and dilute synthetic liquid, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of improving separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of B-ZSM-5 seed layer

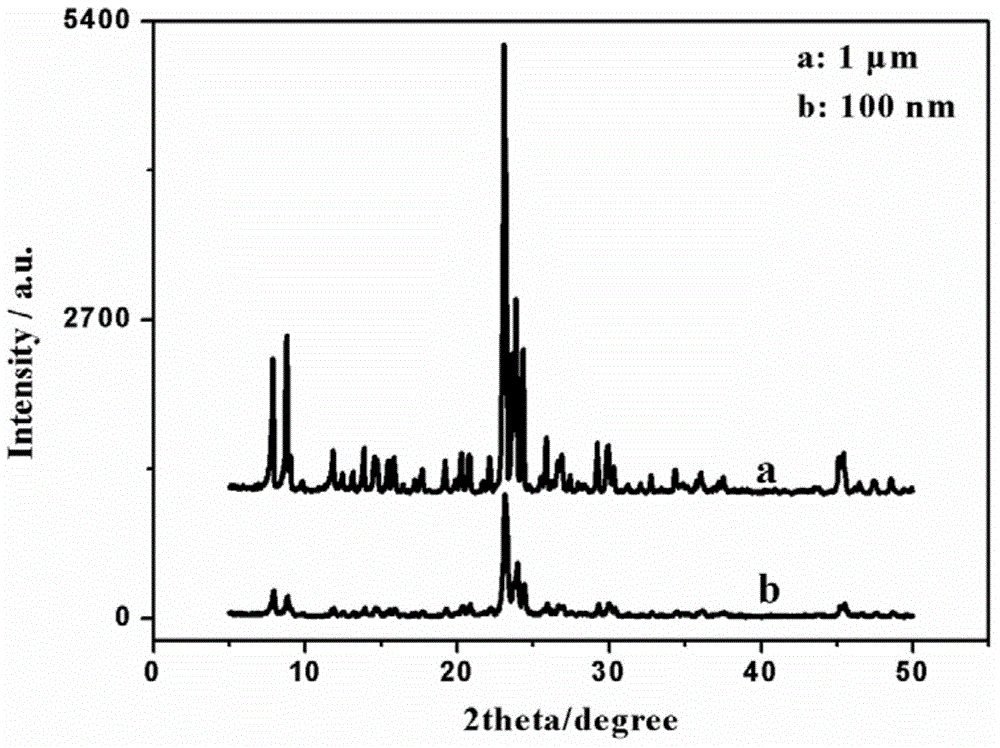

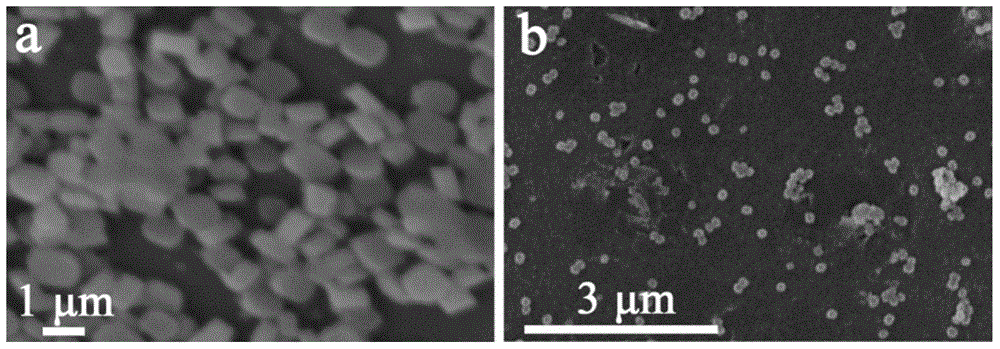

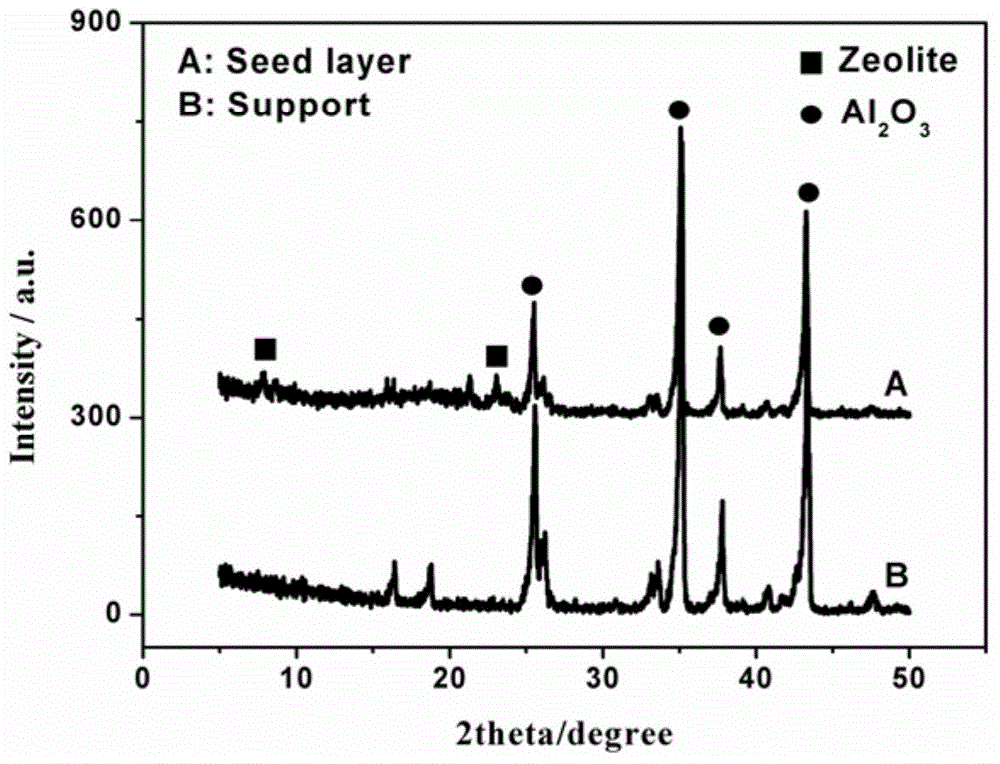

[0030] First, use hot dipping to coat large seed crystals, using such as figure 2 The B-ZSM-5 molecular sieve with a size of 1μm shown in a is used as a large seed crystal. First, the two ends of the alumina carrier tube are sealed with a polytetrafluoroethylene plug, so that the seed crystal can only be introduced to the outer surface of the carrier tube. Place the sealed carrier tube in an oven at 175°C and heat it for 3 hours to cause a pressure difference between the inside and outside of the carrier tube. Put the hot carrier tube into a large seed suspension with a mass concentration of 2wt% for 20 seconds, and then slowly take it out vertically. Then immediately remove the Teflon plug to release the water in the tube, dry it at room temperature, dry it overnight in a 50℃ oven, then put it in a 175℃ oven to solidify the seed layer, and then wipe the carrier tube with degreased cotton Molecular sieve remaining on the surfa...

Embodiment 2

[0032] Example 2 Preparation of B-ZSM-5 molecular sieve membrane

[0033] The carrier used in this experiment to synthesize B-ZSM-5 molecular sieve membrane is the tubular macroporous α-Al provided by Foshan Ceramic Research Institute 2 O 3 The carrier has an inner diameter and an outer diameter of 8 mm and 13 mm, respectively, a length of 80 mm, a porosity of about 36%, and an average pore diameter of about 1-3 μm.

[0034] Preparation of B-ZSM-5 molecular sieve membrane: Seal both ends of the carrier tube coated with the seed layer and put it into a high-pressure reactor with a PTFE liner. The crystallization mother liquor of the membrane should be equipped with B-ZSM -5 seed crystals are prepared by the method of synthetic solution, and its molar composition is 1TEOS:0.2TPAOH:0.06B(OH) 3 :600H 2 O, the synthetic solution after stirring and clarification is slowly poured into the autoclave, sealed and put into a 175℃ oven to react for 24h. After the reaction, the membrane tube is ...

Embodiment 3

[0035] Example 3 Pervaporation performance test

[0036] The template-removed B-ZSM-5 molecular sieve membrane passes such as Figure 5 The shown pervaporation device tests its separation performance, in which the heating belt heats the raw material liquid to a certain temperature, the magnetic stirrer stirs the raw material liquid to keep the temperature and concentration of the raw material liquid uniform, and the membrane tube is sealed at one end with a separator and put in the material liquid The other end of the tank is connected to a vacuum pump through a cold trap cooled by liquid nitrogen, and the osmotic pressure is maintained at about tens of Pa. Driven by the pressure difference, the vapor permeating the membrane is condensed in the cold trap by liquid nitrogen. The pervaporation performance of the membrane is represented by the permeation flux J and the separation coefficient S. The permeation flux J represents the unit membrane area per unit time (t / h) (A / m 2 ) The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com