Preparation method of chitosan/hydroxyapatite magnetic bone repair support material

A technology for hydroxyapatite and scaffolding materials, applied in the field of chemical and biological engineering materials, can solve the problems of poor biocompatibility and limited sources, and achieve the effects of good mechanical properties, easy operation and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

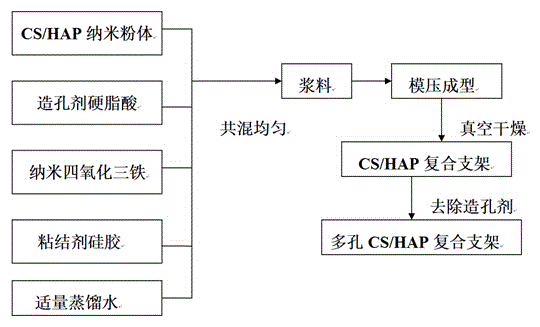

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve formic acid (mass percentage concentration: 2%) in water to prepare a formic acid aqueous solution with a mass percentage concentration of 2.5%, dissolve chitosan in the formic acid solution at a ratio of 0.4g / mL, and heat the lower shell in a water bath at 50°C After the polysaccharide is completely dissolved, let it stand for 1 hour to defoam;

[0032] (2) Dissolving phosphoric acid (mass percentage concentration is 85%) in the solution obtained in step (1), then adding distilled water to dilute to obtain phosphoric acid solution, the volume percent concentration of phosphoric acid in the phosphoric acid solution is 0.1%;

[0033] (3) Dissolve calcium hydroxide in water at a ratio of 1.25g / mL, and stir well to obtain calcium salt lye;

[0034] (4) According to the ratio of calcium hydroxide to phosphoric acid molar ratio of 1.5:1, co-titrate the phosphoric acid solution obtained in step (2) and the calcium salt alkali solution obtained in step (3) in the ...

Embodiment 2

[0040] (1) Dissolve citric acid (3% by mass) in water to prepare a citric acid aqueous solution with a concentration of 4% by mass, dissolve chitosan in the citric acid solution at a ratio of 0.5g / mL, and place in a 60°C water bath Stand still 1.5h degassing after chitosan dissolves completely under heating;

[0041] (2) Dissolve phosphoric acid (mass percentage concentration is 87%) in the solution obtained in step (1), then add distilled water to dilute to obtain phosphoric acid solution, the volume percent concentration of phosphoric acid in the phosphoric acid solution is 0.15%;

[0042] (3) Dissolve calcium hydroxide in water at a ratio of 1.4g / mL, and stir well to obtain calcium salt lye;

[0043] (4) According to the ratio of calcium hydroxide to phosphoric acid molar ratio of 1.6:1, co-titrate the phosphoric acid solution obtained in step (2) and the calcium salt alkali solution obtained in step (3) in the aqueous solution, and co-precipitate for 8 hours. Wherein the ...

Embodiment 3

[0049] (1) Dissolve lactic acid (4% by mass) in water to prepare an aqueous lactic acid solution with a concentration of 5% by mass, dissolve chitosan in the lactic acid solution at a ratio of 0.6g / mL, and heat the lower shell in a water bath at 70°C After the polysaccharide is completely dissolved, let it stand for 2 hours to defoam;

[0050] (2) Dissolving phosphoric acid (mass percentage concentration is 89%) in the solution obtained in step (1), then adding distilled water to dilute to obtain phosphoric acid solution, the volume percent concentration of phosphoric acid in the phosphoric acid solution is 0.2%;

[0051] (3) Dissolve calcium hydroxide in water at a ratio of 1.5g / mL, and stir well to obtain calcium salt lye;

[0052] (4) According to the ratio of calcium hydroxide to phosphoric acid molar ratio of 1.7:1, co-titrate the phosphoric acid solution obtained in step (2) and the calcium salt alkali solution obtained in step (3) in the aqueous solution, and co-precipi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com