Method for Measuring Radon Emissions in Return Air Shafts of Uranium Mine

A technology of air return shaft and discharge volume, which is applied in the field of uranium mining and metallurgy industry, can solve the problems that cannot meet the requirements of radiation protection and evaluation of uranium ore, and achieve measurement accuracy, small sampling uncertainty and statistical fluctuation, Highly Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A method for measuring radon emission in return air shafts of uranium mines, the specific measurement method is as follows:

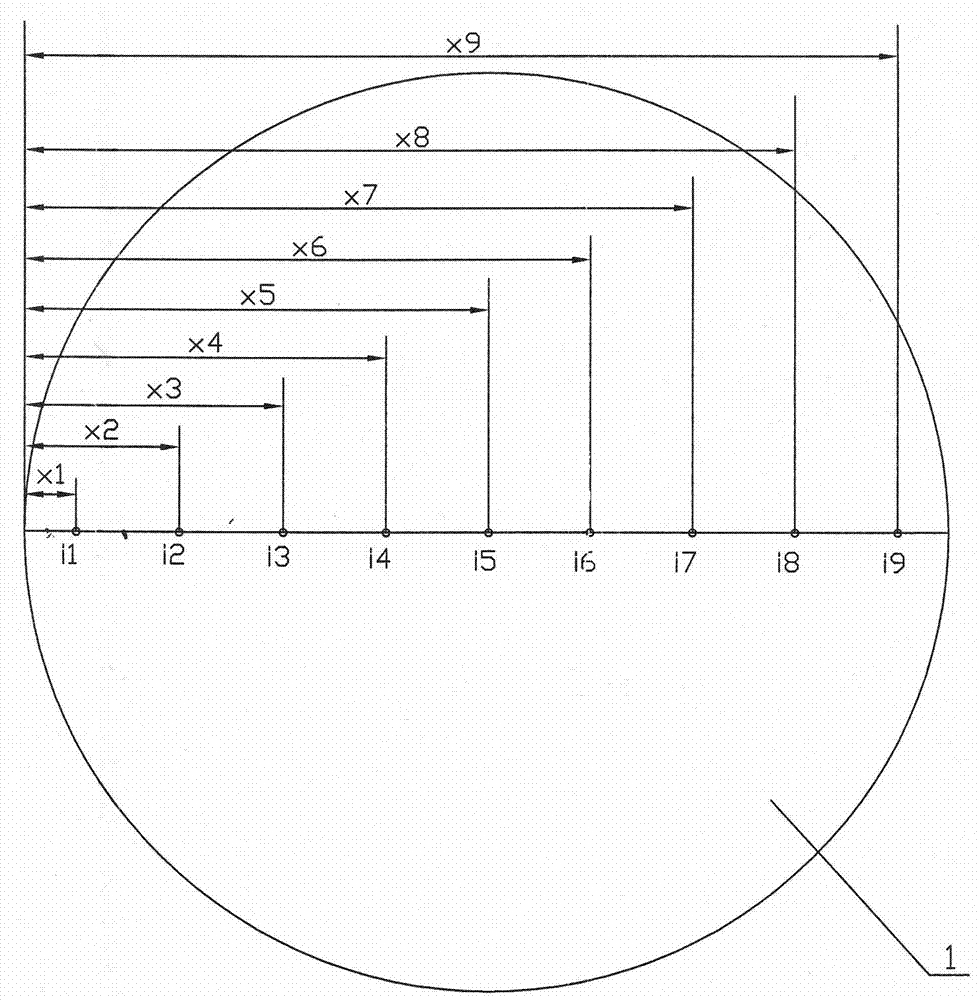

[0038] The present embodiment adopts nine-point method to measure, at first adopts nine-point method to measure wind speed Vi and radon concentration Ci at each point of a certain section in the wellhead of return air shaft 1, wherein nine sampling points are respectively away from return air shaft 1 well wall distance : x1 is 3%d; x2 is 10%d; x3 is 20%d; x4 is 30%d; x5 is 50%d; x6 is 70%d; x7 is 80%d; x8 is 90%d; x9 is 97%d; where d is the outlet diameter of return air shaft 1, in m.

[0039] According to the measured wind speed values at the nine sampling points, the expression formula of the wind speed V and the radial distance x of the return air shaft 1 is deduced by interpolation method:

[0040]

[0041] get:

[0042]

[0043]

[0044]

[0045]

[0046]

[0047]

[0048]

[0049]

[0050] In the formula, V is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com