Fault detection device and method for a flue transducer

A technology of fault detection and transducer, which is applied in the direction of detecting the appearance of fluid at the leakage point and measuring the liquid tightness by using liquid/vacuum degree, etc., which can solve the problems of flue blockage and dust deposition, etc., and prolong the service life , good thermal conductivity, reduce the effect of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

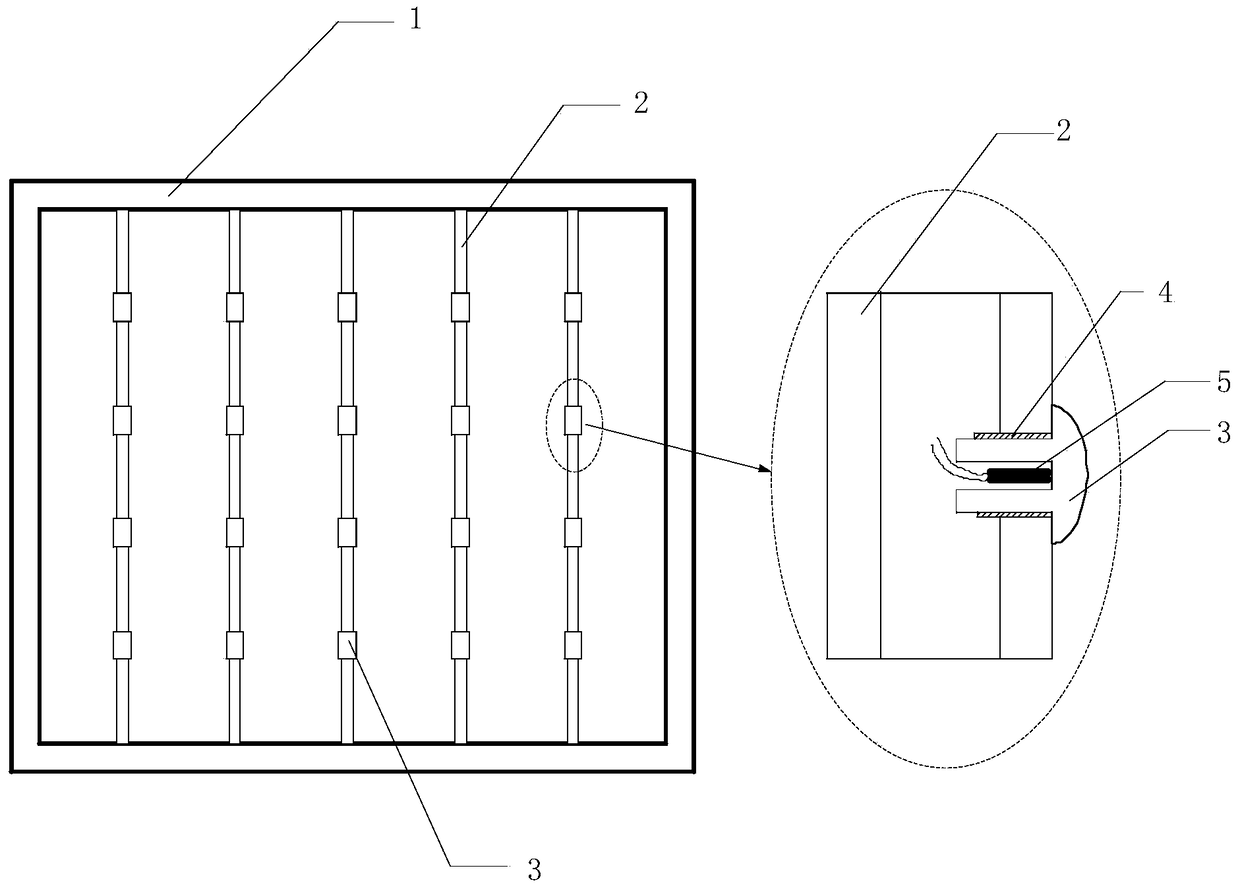

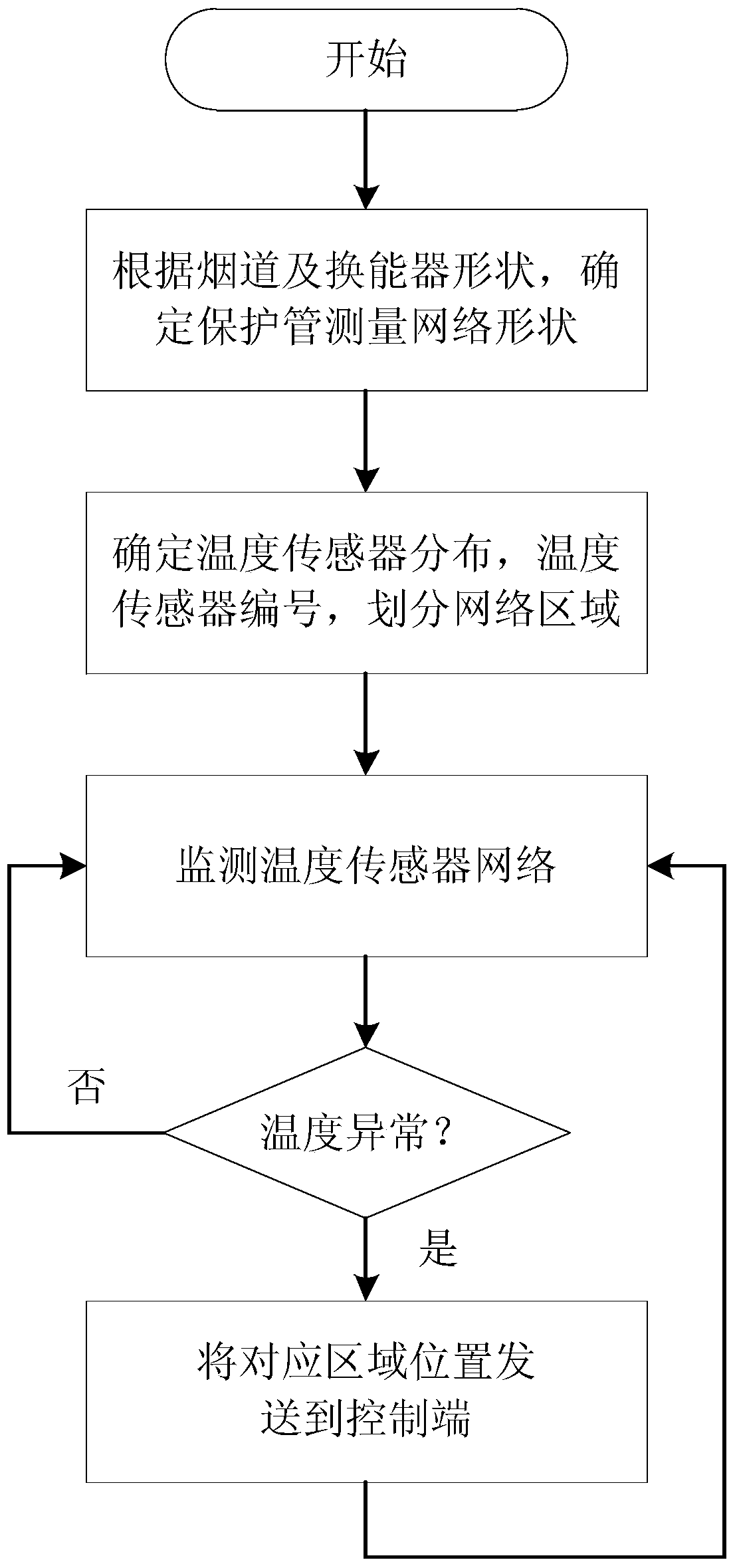

[0020] A flue transducer fault detection device of the present invention includes a protective tube measurement network 1, a protective tube 2, a protective cover 3, a sleeve hole 4, a temperature sensor 5 and a control board, wherein the temperature sensor 5 is used to measure the Temperature, the protective cover 3 is used to conduct heat in the area and protect the temperature sensor 5, the cover hole 4 is used to install the protective cover 3, the protective cover 3 matches the cover hole 4; the protective tube 2 is a hollow tubular structure, and the protective tube 2 There are several evenly distributed sleeve holes 4, and the temperature sensor 5 is fixed in the protective sleeve 3 with heat-conducting silica gel; The internal space is electrically connected to the control board.

[0021] The protective tube measurement network 1 is composed of several protective tubes; the shape and size of the protective tube measurement network 1 are designed according to the shape ...

Embodiment 2

[0023] On the basis of Embodiment 1, further, the protection tube 2 is made of wear-resistant corundum material; corundum tubes are ready-made products in the market, and the cost is relatively low.

[0024] The protective sleeve 2 is a screw with a hollow structure, and the sleeve hole 4 is a screw hole matching the screw. The screw is made of steel material, which has good thermal conductivity and has sufficient supply in the market. , and the price is relatively cheap, easy to process.

Embodiment 3

[0026] On the basis of Embodiment 1, further, the temperature sensor 5 is a thermocouple. When installing, the thermocouple probe is fixed on the side of the screw that meets the flue gas through a material with good thermal conductivity and adhesion ability such as heat-conducting silica gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com