Manufacturing method of polyimide/polyacrylonitrile-based blended pre-oxidized fiber

A technology of pre-oxidizing fiber and polyimide, which is applied in the field of fiber, can solve the problems of low thermal expansion coefficient of heat transfer, difficult preparation, low output, etc., and achieve the effect of improving time-consuming and improving the degree of pre-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

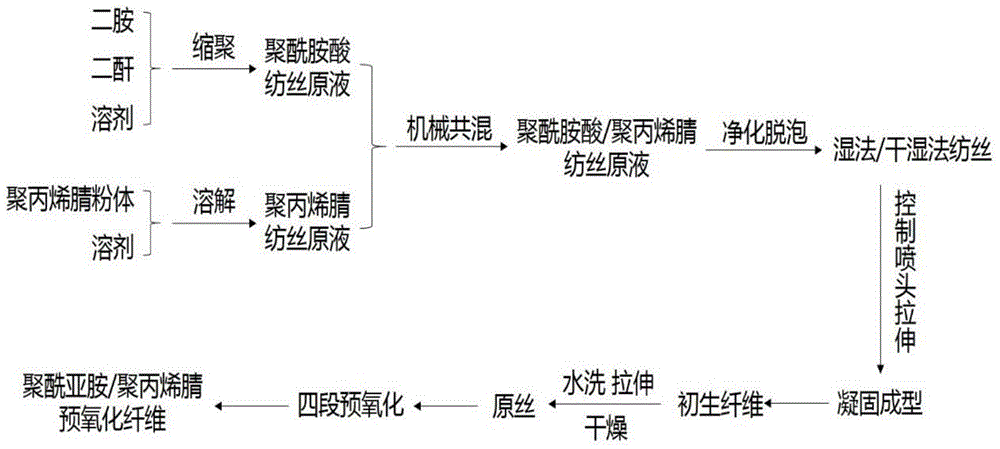

Method used

Image

Examples

Embodiment 1

[0038] A: Synthesis of polyamic acid / polyacrylonitrile blend spinning solution. BPDA, ODA and p-PDA are mechanically stirred in DMSO at low temperature for a certain period of time to prepare a polyamic acid solution of BPDA / ODA / p-PDA. N 2 Under protective conditions, the PAN powder was dissolved in DMSO to obtain a PAN solution. N 2 Under protective conditions, a certain amount of PAN solution is added to the PAA system, and the PAN accounts for 2% of the mass fraction of the PAA (excluding solvent).

[0039] B: Preparation of polyamic acid / polyacrylonitrile blended as-spun fibers. The blended spinning solution is degassed, and the primary fiber is prepared by wet spinning process.

[0040] C: Preparation of polyamic acid / polyacrylonitrile blend precursors. The blended primary fiber is subjected to layered heating treatment, which makes it pass through 60°C, 70°C, 80°C, and 110°C in sequence to complete dehydration and solvent removal.

[0041] D: Preparation of polyimi...

Embodiment 2

[0043] A: Synthesis of polyamic acid / polyacrylonitrile blend spinning solution. BPDA, ODA and p-PDA are mechanically stirred in DMSO at low temperature for a certain period of time to prepare a polyamic acid solution of BPDA / ODA / p-PDA. N 2 Under protective conditions, the PAN powder was dissolved in DMSO to obtain a PAN solution. N 2 Under protective conditions, a certain amount of PAN solution is added to the PAA system, and the PAN accounts for 2% of the mass fraction of the PAA (excluding solvent).

[0044] B: Preparation of polyamic acid / polyacrylonitrile blended as-spun fibers. The blended spinning solution is degassed, and the primary fiber is prepared by wet spinning process.

[0045] C: Preparation of polyamic acid / polyacrylonitrile blend precursors. The blended primary fiber is subjected to layered heating treatment, which makes it pass through 60°C, 70°C, 80°C, and 110°C in sequence to complete dehydration and solvent removal.

[0046] D: Preparation of polyimi...

Embodiment 3

[0048] A: Synthesis of polyamic acid / polyacrylonitrile blend spinning solution. BPDA, ODA and p-PDA are mechanically stirred in DMSO at low temperature for a certain period of time to prepare a polyamic acid solution of BPDA / ODA / p-PDA. Dissolve PAN powder in DMSO to prepare PAN solution. A certain amount of PAN solution is added into the PAA system, and the PAN accounts for 10% of the mass fraction of the PAA (excluding solvent).

[0049] B: Preparation of polyamic acid / polyacrylonitrile blended as-spun fibers. The blended spinning solution is degassed, and the primary fiber is prepared by wet spinning process.

[0050] C: Preparation of polyamic acid / polyacrylonitrile blend precursors. The blended primary fiber is subjected to layered heating treatment, and it passes through 90°C, 100°C, 120°C, and 160°C in sequence to complete dehydration and solvent removal.

[0051] D: Preparation of polyimide / polyacrylonitrile blended preoxidized fibers. The blended raw silk is subje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com